How pure should Pure Artemisinin Powder be for clinical use?

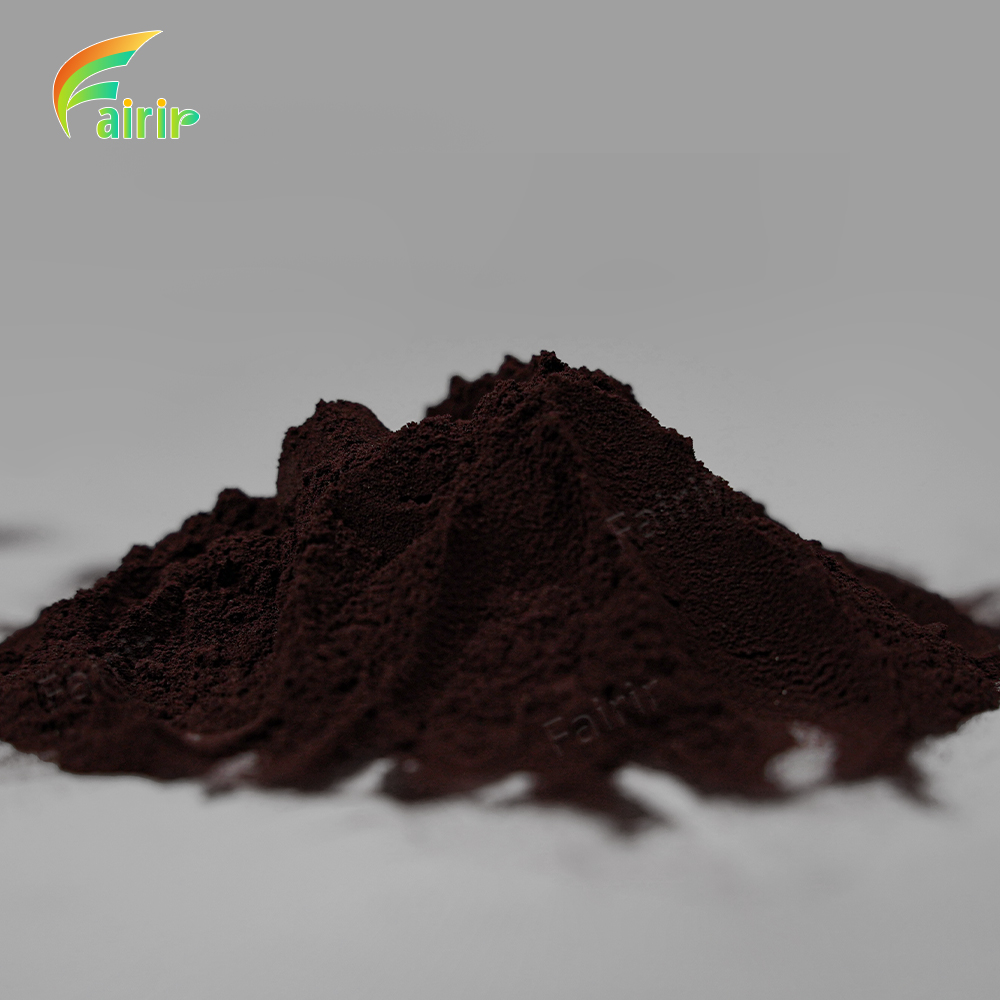

Unadulterated Artemisinin Powder, also known as Pure Artemisinin Powder, is presently an vital portion of the battle against jungle fever, which is one of the most exceedingly bad illnesses in the world. As researchers and specialists proceed to see into its conceivable employments, an critical address comes up: How unadulterated ought to Immaculate Artemisinin Powder be for therapeutic utilize? This is the most critical address since the immaculateness of the compound has a coordinate impact on how well it works, how secure it is, and how valuable it is as a medication for the most part. When precision and steadfastness are exceptionally critical, like in a clinic, the quality of artemisinin is exceptionally vital for making beyond any doubt that patients get the best care. This web journal post goes into detail around the complicated immaculateness guidelines of Unadulterated Artemisinin Powder. It talks almost the things that influence its quality, the current measures in the trade, and what these measures cruel for clinical employments. By learning around the distinctive sorts of artemisinin immaculateness, we can superior get it the troubles and chances of utilizing this solid antimalarial medicate in healthcare circumstances in the best way conceivable.

What are the quality standards for Pure Artemisinin Powder in pharmaceutical production?

Chemical purity requirements

The chemical purity of Pure Artemisinin Powder is a critical factor in pharmaceutical production. Industry standards typically require a minimum purity of 98% for clinical use. This high level of purity makes sure that there are enough of the active chemical and as few impurities as possible. To get to this level of purity, complex extraction and processing methods are needed. Pure Artemisinin Powder makers have to use high-tech analysis methods like Gas Chromatography (GC) and High-Performance Liquid Chromatography (HPLC) to make sure the powder is pure and find any possible contaminants. There are many impurities in pharmaceutical products, and even small amounts can change how stable, effective, and safe the end product is.

Microbiological standards

In addition to chemical purity, Pure Artemisinin Powder must meet stringent microbiological standards for clinical use. This includes making sure the powder doesn't have any bacteria, fungi, or other germs that could make patients less safe. Microbiological tests must be done thoroughly by manufacturers. These tests must include a total aerobic microbial count, a total yeast and mold count, and tests for specific diseases. The production environment for Pure Artemisinin Powder must be carefully controlled to prevent microbial contamination. This often involves the use of clean rooms, sterile processing equipment, and strict hygiene protocols for personnel handling the product.

Stability and storage requirements

The stability of Pure Artemisinin Powder is another crucial aspect of its quality standards. The chemical has to stay pure and effective over time even when stored in different ways. Stability studies are done by manufacturers to find out how to store Pure Artemisinin Powder most effectively and how long it will last. Usually, the powder should be kept in cases that don't let air in, away from light and moisture, and at a steady temperature. The way Pure Artemisinin Powder is packed is very important for keeping its quality. Many manufacturers use vacuum-sealed aluminum foil bags or fiber drums with double-layer food-grade poly bags to ensure the powder's integrity during storage and transportation.

How does the purity of Artemisinin Powder affect its efficacy in treating malaria?

Impact on dosage and bioavailability

The purity of Pure Artemisinin Powder directly influences its efficacy in treating malaria by affecting the dosage and bioavailability of the active compound. More pure powder means that less of it is needed to get the beneficial effect that is wanted. This means that dosing is more accurate and side effects may be lessened. Pure Artemisinin Powder that is very pure also tends to have better bioavailability, which means that the body can take and use the compound better. This higher bioavailability can make the medicine work faster and give more regular results when treating malaria. Manufacturers of Pure Artemisinin Powder must carefully control the purity to ensure that each batch delivers the expected potency and efficacy.

Reduction of side effects

The virtue of Immaculate Artemisinin Powder plays a pivotal part in minimizing potential side impacts related with intestinal sickness treatment. Individuals may have unusual reactions or issues if the powder isn't unadulterated. Making beyond any doubt the drugs are exceptionally unadulterated makes a difference companies lower the chance of side impacts and make artemisinin-based medications more secure all around. Analysts can conduct more exact pharmacokinetic and pharmacodynamic ponders with Unadulterated Artemisinin Powder that contains few debasements. These thoughts are important for figuring out the best ways to treat people and finding out how drugs may interact with each other. When Unadulterated Artemisinin Powder is utilized in combination medicines, this level of immaculateness is particularly imperative since it makes a difference keep diverse dynamic fixings from responding in ways that were not anticipated.

Resistance prevention

Maintaining high purity standards for Pure Artemisinin Powder is crucial in the ongoing battle against antimalarial drug resistance. When you use low-quality or unpure artemisinin products, they can help the malaria parasite become immune to them. Patients receive the full therapeutic amount of Pure Artemisinin Powder, which lowers the risk of incomplete treatment and the emergence of resistance. Also, the purity of Pure Artemisinin Powder stays the same across batches. This helps people believe and repeat clinical results more often, which is important for stopping the spread of malaria types that are hard to treat around the world.

What are the challenges in producing high-purity Artemisinin Powder for clinical applications?

Extraction and purification processes

Producing high-purity Pure Artemisinin Powder for clinical applications presents several challenges, particularly in the extraction and purification processes. The artemisinin content in the Artemisia annua plant is relatively low, typically ranging from 0.01% to 1.4% of dry leaf weight, making efficient extraction crucial. To get the most output while keeping the purity, advanced methods like supercritical CO2 extraction are often used. But these ways can be expensive and use a lot of energy. Once the Pure Artemisinin Powder is extracted, it needs to go through several steps of cleaning to get rid of any plant impurities and reach the desired level of purity. Steps like crystallization, filtration, and recrystallization can be in this list. Each one makes the production process more difficult and expensive

Quality control and consistency

Maintaining consistent quality and purity across different batches of Pure Artemisinin Powder is a significant challenge in production. Variations in plant material quality, environmental factors during cultivation, and slight differences in processing conditions can all impact the final purity of the product. At every step of the production process, from choosing the raw materials to testing the finished product, strict quality control measures must be in place. As part of this, Good Manufacturing Practices (GMP) must be followed and regular scientific testing must be done using tools like HPLC and spectroscopy. Making sure that Pure Artemisinin Powder is consistent from batch to batch is important for accurate clinical results and following the rules, which means spending a lot of money on quality control tools and training staff.

Scalability and cost-effectiveness

Scaling up the production of high-purity Pure Artemisinin Powder while maintaining cost-effectiveness poses significant challenges. As the need for treatments based on artemisinin grows, companies that make them need to find ways to make more of them without lowering the quality or making the prices go through the roof. Often, this means spending a lot of money on high-tech tools for extraction and purification and making sure that processes are run as efficiently as possible. The seasonal nature of Artemisia annua cultivation and the variability in artemisinin content can also complicate large-scale production planning. To deal with these problems, some companies are looking into different ways to make artemisinin, like semi-synthetic artemisinin production, which might provide a more steady supply and higher quality of Pure Artemisinin Powder for medical uses.

Conclusion

To whole up, the quality of Immaculate Artemisinin Powder is a exceptionally critical portion of how it is utilized to treat jungle fever. Pharmaceutical employments require tall immaculateness measures, more often than not 98% or higher, to make beyond any doubt that the medicate works, is secure, and is continuously the same. Getting and keeping such tall levels of virtue is exceptionally difficult in terms of extraction, filtration, and quality control, but it is fundamental to battle intestinal sickness effectively and halt medicate resistance. As innovation and ponder make strides, it will be critical to keep working to progress generation strategies and keep quality benchmarks tall in arrange to get the most out of Unadulterated Artemisinin Powder in clinical settings.

Shaanxi Fairir Biotech Co., Ltd. is proud to be the leading manufacturer and supplier of high-quality plant extracts, including Pure Artemisinin Powder. We have a great name for sending high-quality botanical ingredients to businesses all over the world. Our state-of-the-art 10,000㎡ GMP-certified production plant features 23 stainless steel extraction tanks and three fully automated production lines, achieving 98% purity in our products. Our comprehensive quality management system, adhering to international certifications such as GMP, ISO 9001, and HACCP, ensures the highest standards of quality and safety. With our advanced extraction technologies, including solvent-free CO₂ supercritical extraction, we provide superior bioactivity retention in our Pure Artemisinin Powder. For inquiries or to learn more about our products, please contact us at sales@fairirbiotech.com.

References

1. World Health Organization. (2021). Guidelines for malaria vector control. Geneva: WHO.

2. Tu, Y. (2011). The discovery of artemisinin (qinghaosu) and gifts from Chinese medicine. Nature Medicine, 17(10), 1217-1220.

3. Hien, T. T., & White, N. J. (1993). Qinghaosu. The Lancet, 341(8845), 603-608.

4. Efferth, T. (2017). From ancient herb to modern drug: Artemisia annua and artemisinin for cancer therapy. Seminars in Cancer Biology, 46, 65-83.

5. Kumar, S., & Pandey, A. K. (2013). Chemistry and biological activities of flavonoids: an overview. The Scientific World Journal, 2013, 162750.

6. Paddon, C. J., & Keasling, J. D. (2014). Semi-synthetic artemisinin: a model for the use of synthetic biology in pharmaceutical development. Nature Reviews Microbiology, 12(5), 355-367.

_1751965378790.webp)