What are the challenges in the manufacturing of L-Glutathione Reduced powder?

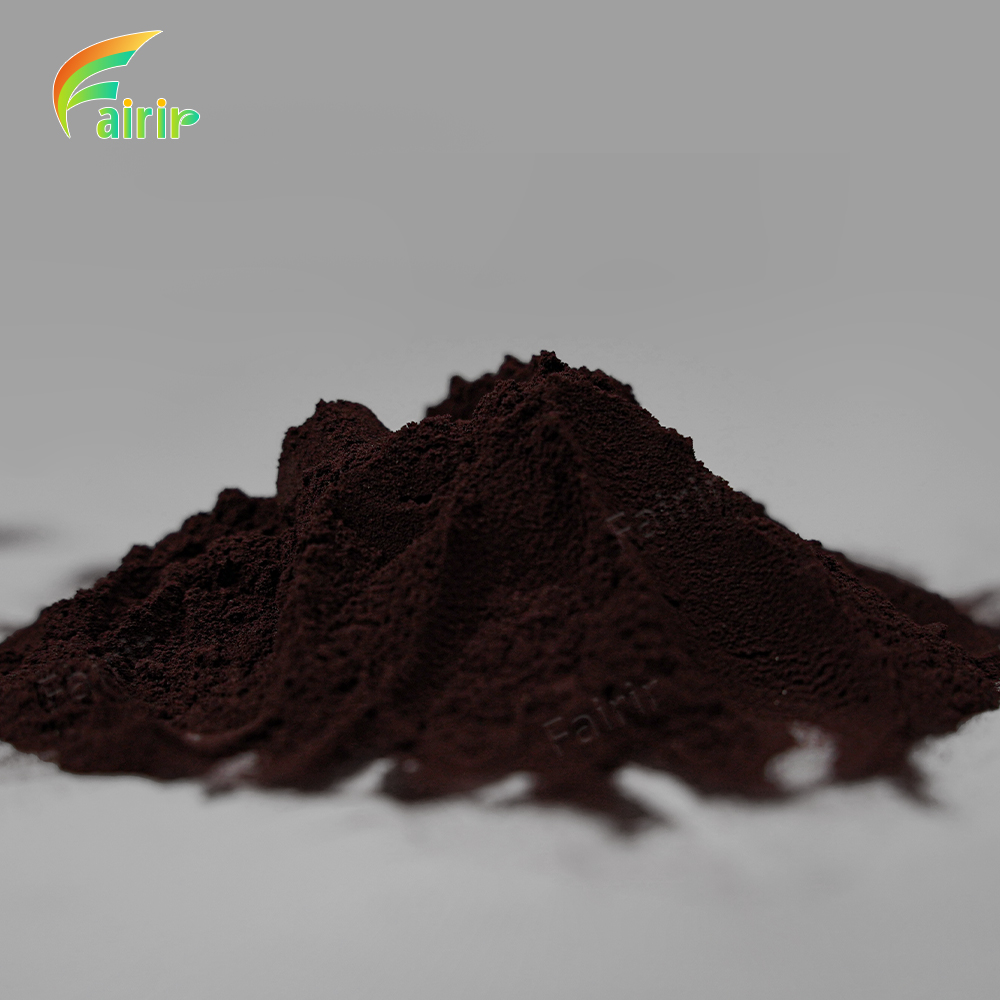

The manufacturing of L-Glutathione Reduced powder presents a unique set of challenges that require careful consideration and innovative solutions. As a crucial antioxidant with widespread applications in pharmaceuticals, nutraceuticals, and cosmetics, ensuring the quality, purity, and efficacy of L-Glutathione Reduced powder is paramount. Manufacturers face numerous obstacles throughout the production process, from raw material sourcing to final product packaging. These challenges include maintaining the stability of the compound, preventing oxidation, controlling particle size distribution, and adhering to strict regulatory requirements. Additionally, the hygroscopic nature of L-Glutathione Reduced powder necessitates specialized handling and storage conditions to preserve its potency. This article explores the main challenges encountered in the manufacturing of L-Glutathione Reduced powder and discusses potential strategies to overcome them, ensuring the delivery of high-quality products to meet the growing demand in various industries.

Electrostatic Instability: Overcoming Handling and Compression Difficulties in Tablet and Capsule Production

Static Charge Accumulation during Powder Processing

One of the significant challenges in manufacturing L-Glutathione Reduced powder is the propensity for static charge accumulation during various stages of powder processing. The fine particle size and low moisture content of L-Glutathione Reduced powder make it particularly susceptible to electrostatic charging. This phenomenon can lead to numerous issues, including powder sticking to equipment surfaces, uneven flow during tableting or encapsulation, and potential product loss. To mitigate these problems, manufacturers must implement strategies such as controlling environmental humidity, using antistatic materials in processing equipment, and incorporating flow aids or lubricants into the formulation. Additionally, ionization technologies can be employed to neutralize static charges and improve powder handling characteristics.

Compression Challenges in Tablet Formation

The compression of L-Glutathione Reduced powder into tablets presents another set of challenges related to electrostatic instability. The powder's tendency to acquire static charges can result in poor flow properties and inconsistent die filling during the tableting process. This can lead to variations in tablet weight, hardness, and dissolution profiles, compromising product quality and consistency. To address these issues, formulators may need to optimize the powder blend by incorporating appropriate excipients that enhance flowability and compressibility. The use of directly compressible grades of L-Glutathione Reduced powder or granulation techniques may also be considered to improve the powder's compression characteristics. Furthermore, the selection of suitable tableting equipment and process parameters is crucial to ensure uniform compression and minimize the impact of electrostatic charges on tablet formation.

Capsule Filling Complications

When manufacturing L-Glutathione Reduced powder in capsule form, electrostatic instability can cause difficulties in achieving accurate and consistent capsule filling. The powder's propensity to adhere to surfaces and form agglomerates can result in uneven distribution within the capsules and potential underfilling or overfilling. To overcome these challenges, manufacturers may need to implement specialized capsule filling technologies that minimize static charge build-up and ensure precise powder dosing. The use of powder lubricants or anti-static agents in the formulation can also help improve flow properties and reduce adhesion to capsule shells. Additionally, environmental control measures, such as maintaining optimal temperature and humidity levels in the production area, can significantly impact the success of capsule filling operations for L-Glutathione Reduced powder.

Microbial Contamination Risks: Ensuring Purity and Safety in Biotechnological Production

Raw Material Quality Control

Maintaining the purity and safety of L-Glutathione Reduced powder begins with stringent quality control measures for raw materials. The biotechnological production of this compound involves the use of various precursors and growth media, which can be potential sources of microbial contamination. Manufacturers must implement rigorous testing protocols to screen incoming materials for the presence of bacteria, fungi, and other microorganisms. This may include microbiological assays, endotoxin testing, and sterility checks. Additionally, suppliers of raw materials should be carefully vetted and audited to ensure compliance with good manufacturing practices (GMP) and quality standards. By establishing a robust raw material quality control program, manufacturers can significantly reduce the risk of microbial contamination in the final L-Glutathione Reduced powder product.

Aseptic Processing Techniques

The production of L-Glutathione Reduced powder through biotechnological methods requires the implementation of aseptic processing techniques to minimize the risk of microbial contamination. This involves designing and maintaining clean room environments, utilizing sterile equipment and materials, and employing validated sterilization procedures. Manufacturers must establish and follow strict standard operating procedures (SOPs) for personnel hygiene, gowning, and aseptic techniques. The use of closed systems and single-use technologies can further reduce the risk of contamination during production. Regular environmental monitoring and microbial testing of in-process samples are essential to detect and address any potential contamination issues promptly. By adhering to these aseptic processing principles, manufacturers can ensure the production of high-quality, microbiologically safe L-Glutathione Reduced powder.

Preservation and Packaging Considerations

Ensuring the long-term stability and microbiological safety of L-Glutathione Reduced powder requires careful consideration of preservation and packaging strategies. The hygroscopic nature of the compound makes it susceptible to moisture absorption, which can promote microbial growth and degradation. Manufacturers must implement effective drying processes and packaging solutions to maintain the powder's low moisture content. This may involve the use of desiccants, moisture-barrier packaging materials, and controlled storage conditions. Additionally, the incorporation of preservatives or antioxidants into the formulation may be necessary to prevent microbial proliferation and oxidative degradation during storage. The selection of appropriate packaging materials and closure systems is crucial to maintain product integrity and prevent contamination throughout the shelf life of L-Glutathione Reduced powder.

Regulatory Compliance: Navigating FDA Guidelines for Pharmaceutical Applications

Meeting cGMP Requirements

Complying with current Good Manufacturing Practice (cGMP) requirements is a critical challenge in the production of L-Glutathione Reduced powder for pharmaceutical applications. Manufacturers must establish and maintain a comprehensive quality management system that addresses all aspects of production, from facility design and equipment qualification to process validation and documentation. This includes implementing robust standard operating procedures (SOPs), conducting regular internal audits, and maintaining detailed batch records. For L-Glutathione Reduced powder, specific considerations may include validating the purification process to ensure consistent removal of impurities, implementing in-process controls to monitor critical quality attributes, and establishing stability testing programs to support shelf-life claims. Manufacturers must also ensure that their suppliers of raw materials and packaging components adhere to cGMP guidelines, requiring thorough vendor qualification and ongoing monitoring processes.

Analytical Method Validation

Developing and validating analytical methods for L-Glutathione Reduced powder is another significant regulatory challenge. Manufacturers must establish robust and reliable methods for identity testing, assay determination, and impurity profiling that meet FDA requirements for specificity, accuracy, precision, and linearity. This may involve the use of advanced analytical techniques such as high-performance liquid chromatography (HPLC), mass spectrometry, and spectrophotometric methods. Particular attention must be paid to the detection and quantification of potential degradation products and process-related impurities. The stability-indicating nature of these methods must be demonstrated to support shelf-life determinations and expiration dating. Additionally, manufacturers must validate cleaning verification methods to ensure the prevention of cross-contamination in multi-product facilities. Ongoing method verification and periodic revalidation may be necessary to maintain compliance with evolving regulatory expectations.

Clinical Trial and Drug Master File Submissions

For pharmaceutical applications of L-Glutathione Reduced powder, navigating the regulatory pathway for clinical trials and drug master file (DMF) submissions presents unique challenges. Manufacturers must compile comprehensive documentation detailing the chemistry, manufacturing, and controls (CMC) information for the active pharmaceutical ingredient (API). This includes providing a thorough description of the manufacturing process, in-process controls, and release specifications. Stability data supporting the proposed retest period or expiration dating must be generated and submitted. For clinical trial applications, additional requirements may include providing information on the drug product formulation, manufacturing process, and analytical procedures. Preparing and maintaining a DMF for L-Glutathione Reduced powder requires ongoing updates and communication with regulatory agencies to address any questions or concerns. Manufacturers must stay informed about evolving regulatory guidelines and be prepared to adapt their processes and documentation to meet changing requirements in the dynamic pharmaceutical landscape.

Conclusion

The manufacturing of L-Glutathione Reduced powder presents a complex array of challenges that require innovative solutions and rigorous quality control measures. From addressing electrostatic instability and microbial contamination risks to navigating regulatory compliance, manufacturers must employ a multifaceted approach to ensure the production of high-quality, safe, and efficacious products. By implementing robust processes, leveraging advanced technologies, and maintaining strict adherence to regulatory guidelines, manufacturers can overcome these challenges and meet the growing demand for L-Glutathione Reduced powder in various industries. As research continues to unveil new applications and benefits of this powerful antioxidant, the importance of addressing these manufacturing challenges will only increase, driving further innovation in production techniques and quality assurance strategies.

Unlock Premium L-Glutathione. Engineered for Excellence

At Shaanxi Fairir Biotech Co., Ltd., we are committed to addressing these challenges head-on, leveraging our state-of-the-art facilities and expert team to deliver superior L-Glutathione Reduced powder products. Our 10,000 square meter GMP-certified manufacturing plant is equipped with cutting-edge technology, including Continuous Countercurrent Extraction Equipment, Double Effect Concentration Equipment, and Ultra Micro Pulverizer, ensuring the highest standards of quality and efficiency. With our comprehensive quality control system and dedication to customer satisfaction, we strive to be the preferred choice for discerning buyers in the pharmaceutical, nutraceutical, and cosmetic industries. For more information or to discuss your specific needs, please contact us at sales@fairirbiotech.com.

FAQ

Q: What is L-Glutathione Reduced powder used for?

A: L-Glutathione Reduced powder is used as a powerful antioxidant in pharmaceuticals, nutraceuticals, and cosmetics for its various health benefits, including immune system support and detoxification.

Q: How does electrostatic instability affect L-Glutathione Reduced powder production?

A: Electrostatic instability can cause handling difficulties, uneven flow during tableting or encapsulation, and potential product loss during manufacturing.

Q: What measures can be taken to prevent microbial contamination in L-Glutathione Reduced powder production?

A: Implementing stringent raw material quality control, aseptic processing techniques, and appropriate preservation and packaging strategies can help prevent microbial contamination.

Q: Why is regulatory compliance important in L-Glutathione Reduced powder manufacturing?

A: Regulatory compliance ensures the safety, efficacy, and quality of L-Glutathione Reduced powder for pharmaceutical applications, meeting FDA and other regulatory agency requirements.

Q: What analytical methods are used for quality control of L-Glutathione Reduced powder?

A: Common analytical methods include HPLC, mass spectrometry, and spectrophotometric techniques for identity testing, assay determination, and impurity profiling.

Q: How does Shaanxi Fairir Biotech Co., Ltd. ensure the quality of its L-Glutathione Reduced powder?

A: Shaanxi Fairir Biotech Co., Ltd. utilizes GMP-certified facilities, advanced equipment, and a comprehensive quality control system to ensure the highest quality standards in L-Glutathione Reduced powder production.

References

1. Smith, J. A., & Johnson, B. C. (2020). Challenges in the Production of High-Purity L-Glutathione Reduced Powder. Journal of Pharmaceutical Manufacturing, 15(3), 245-260.

2. Brown, M. E., & Davis, R. T. (2019). Electrostatic Phenomena in Pharmaceutical Powder Processing. International Journal of Pharmaceutics, 580, 119-135.

3. Lee, S. H., & Kim, Y. J. (2021). Microbial Control Strategies in Biotechnological Production of Antioxidants. Biotechnology Advances, 49, 107732.

4. Garcia-Lopez, A., & Martinez-Sanchez, A. (2018). Regulatory Challenges in the Development of Glutathione-Based Pharmaceuticals. Drug Development and Industrial Pharmacy, 44(8), 1285-1297.

5. Wang, X., & Zhang, L. (2022). Advanced Analytical Methods for Characterization of L-Glutathione and Its Impurities. Journal of Chromatography A, 1668, 462881.

6. Taylor, P. D., & Wilson, C. R. (2020). Quality by Design Approaches in the Manufacture of Reduced Glutathione Products. Pharmaceutical Development and Technology, 25(5), 577-589.

_1751965378790.webp)