How is L-Glutathione Reduced powder synthesized and purified?

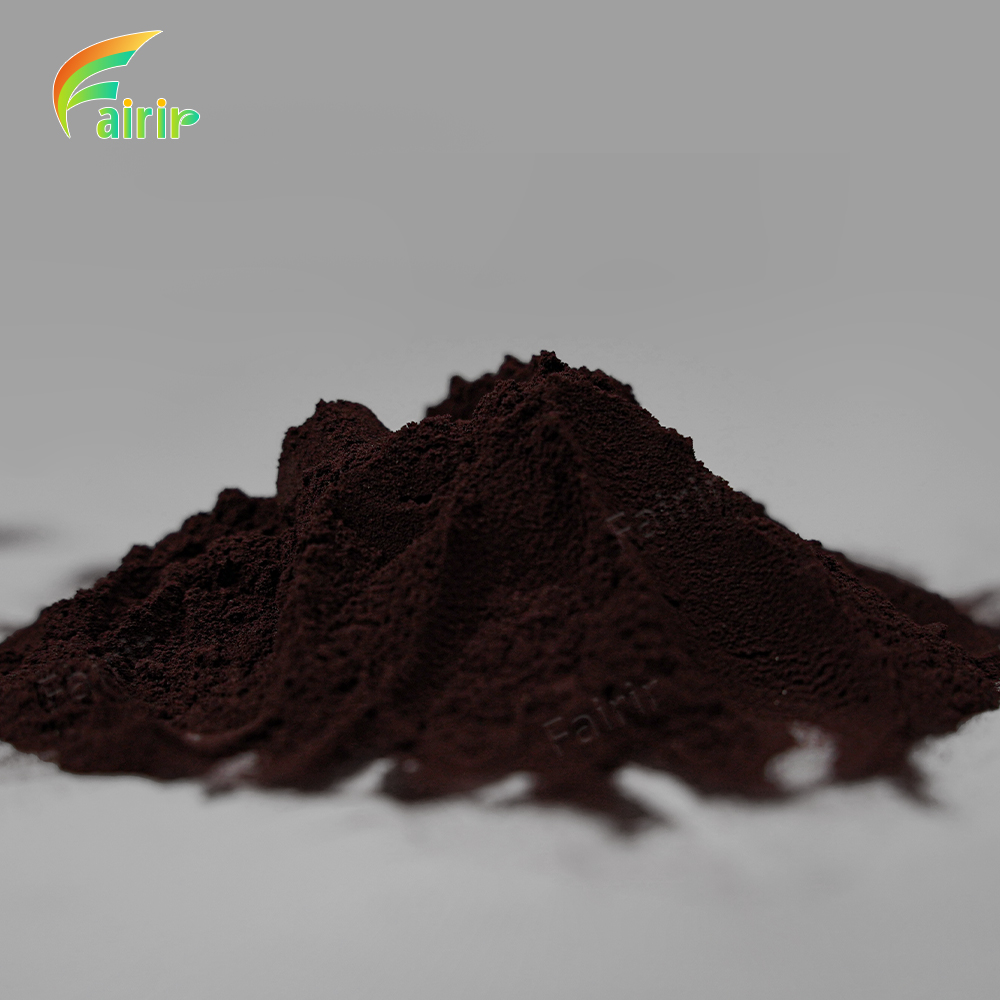

L-Glutathione Reduced powder, a powerful antioxidant and essential component in cellular processes, has gained significant attention in the pharmaceutical, nutraceutical, and cosmetic industries. The synthesis and purification of this vital compound involve complex processes that ensure its high quality and efficacy. This blog post delves into the intricate methods used to produce L-Glutathione Reduced powder, exploring various techniques such as fermentation-based biosynthesis, chemical synthesis, and purification methods. By understanding these processes, we can appreciate the advanced technology and expertise required to manufacture this valuable supplement, which plays a crucial role in maintaining overall health and well-being. Join us as we uncover the fascinating journey of L-Glutathione Reduced powder from its synthesis to the final purified product ready for use in various applications.

Fermentation-based Biosynthesis of L-Glutathione Reduced Using Yeast and Engineered Microbes

Yeast Fermentation Process

The yeast fermentation process is a widely used method for the biosynthesis of L-Glutathione Reduced powder. This technique involves carefully selected strains of Saccharomyces cerevisiae, which naturally produce glutathione as part of their metabolic processes. The yeast cells are cultivated in a controlled environment with optimized nutrient media, temperature, and pH conditions. As the yeast grows and multiplies, it synthesizes L-Glutathione Reduced powder intracellularly. The process is monitored closely to ensure maximum yield and purity of the final product. Once the fermentation is complete, the yeast cells are harvested, and the L-Glutathione Reduced powder is extracted using various techniques such as cell lysis and centrifugation. This method is preferred for its cost-effectiveness and ability to produce large quantities of high-quality L-Glutathione Reduced powder.

Engineered Microbes for Enhanced Production

To improve the efficiency and yield of L-Glutathione Reduced powder production, researchers have developed engineered microbes through genetic modification. These microorganisms, often bacteria or yeast, are designed to overexpress the enzymes involved in glutathione biosynthesis. By manipulating the genetic makeup of these microbes, scientists can create strains that produce significantly higher amounts of L-Glutathione Reduced powder compared to their wild-type counterparts. The engineered microbes are cultivated in bioreactors under carefully controlled conditions, allowing for optimal growth and production. This advanced biotechnological approach not only increases the overall yield but also enables the production of L-Glutathione Reduced powder with enhanced purity and consistency. The use of engineered microbes represents a significant advancement in the field of glutathione synthesis, offering a more efficient and sustainable method for large-scale production.

Optimization of Fermentation Parameters

The success of fermentation-based biosynthesis of L-Glutathione Reduced powder heavily relies on the optimization of various fermentation parameters. Factors such as temperature, pH, dissolved oxygen levels, and nutrient composition play crucial roles in maximizing the production and quality of the final product. Researchers and manufacturers continuously fine-tune these parameters to achieve the highest possible yield and purity of L-Glutathione Reduced powder. Advanced monitoring systems and sophisticated control algorithms are employed to maintain optimal conditions throughout the fermentation process. Additionally, fed-batch or continuous fermentation techniques may be utilized to further enhance productivity. By carefully optimizing these parameters, manufacturers can ensure consistent production of high-quality L-Glutathione Reduced powder that meets the stringent standards required for pharmaceutical and nutraceutical applications.

Chemical Synthesis and Electroreduction Methods for Converting Oxidized Glutathione (GSSG) to the Reduced Form (GSH)

Chemical Reduction of GSSG

Chemical reduction of oxidized glutathione (GSSG) to its reduced form (GSH) is a widely used method for producing L-Glutathione Reduced powder. This process involves the use of reducing agents such as sodium borohydride or dithiothreitol (DTT) to break the disulfide bond in GSSG, resulting in the formation of two GSH molecules. The reaction is typically carried out under controlled conditions, including precise temperature and pH regulation, to ensure optimal conversion rates. After the reduction process, the resulting L-Glutathione Reduced powder is separated from the reaction mixture using various purification techniques. This method is favored for its ability to produce large quantities of L-Glutathione Reduced powder efficiently, making it suitable for industrial-scale production. However, care must be taken to remove any residual reducing agents and by-products to ensure the purity and safety of the final product.

Electrochemical Reduction Techniques

Electrochemical reduction offers an innovative approach to converting oxidized glutathione (GSSG) to L-Glutathione Reduced powder. This method utilizes an electrochemical cell, where GSSG is reduced at the cathode through the application of an electrical current. The process is carried out in an aqueous solution, often containing a supporting electrolyte to enhance conductivity. By carefully controlling the electrode potential and current density, manufacturers can achieve high conversion rates with minimal side reactions. One of the main advantages of electrochemical reduction is its environmental friendliness, as it eliminates the need for chemical reducing agents. Additionally, this technique allows for precise control over the reduction process, resulting in L-Glutathione Reduced powder with high purity. The electrochemical approach is gaining popularity in the production of pharmaceutical-grade L-Glutathione Reduced powder due to its efficiency and potential for scalability.

Enzymatic Conversion of GSSG to GSH

Enzymatic conversion represents a biocatalytic approach to synthesizing L-Glutathione Reduced powder from its oxidized form (GSSG). This method employs glutathione reductase, an enzyme that naturally catalyzes the reduction of GSSG to GSH in biological systems. The enzymatic process is carried out in a controlled environment, typically using NADPH as a cofactor to drive the reaction. One of the key advantages of this technique is its high specificity, resulting in L-Glutathione Reduced powder with excellent purity. The mild reaction conditions required for enzymatic conversion also make it suitable for producing pharmaceutical-grade L-Glutathione Reduced powder. However, the cost of enzymes and cofactors can be a limiting factor for large-scale production. To address this, researchers are exploring immobilized enzyme systems and enzyme recycling techniques to improve the economic viability of enzymatic conversion for industrial-scale synthesis of L-Glutathione Reduced powder.

Purification Techniques: Extraction, Crystallization, and Removal of Impurities to Achieve Pharmaceutical-Grade GSH Powder

Solvent Extraction and Liquid-Liquid Partitioning

Solvent extraction and liquid-liquid partitioning are crucial steps in the purification of L-Glutathione Reduced powder. These techniques leverage the differential solubility of glutathione and impurities in various solvents to achieve separation. The crude L-Glutathione Reduced powder is typically dissolved in an aqueous solution, and then an organic solvent is added to create a two-phase system. As the compounds distribute between the two phases based on their solubility characteristics, the L-Glutathione Reduced powder can be selectively extracted into one phase while leaving impurities in the other. Multiple extraction cycles may be performed to enhance purity. The choice of solvents is critical, considering factors such as selectivity, toxicity, and ease of removal. After extraction, the solvent containing the purified L-Glutathione Reduced powder is carefully evaporated under controlled conditions to prevent oxidation. This method is particularly effective for removing non-polar impurities and is often used as an initial purification step in the production of high-quality L-Glutathione Reduced powder.

Crystallization and Recrystallization Processes

Crystallization and recrystallization are essential purification techniques used to obtain pharmaceutical-grade L-Glutathione Reduced powder. These processes exploit the principle of solubility differences between the desired compound and impurities. In the crystallization step, a saturated solution of crude L-Glutathione Reduced powder is prepared and then carefully cooled or subjected to antisolvent addition, causing the pure compound to form crystals while impurities remain in solution. The crystals are then separated from the mother liquor by filtration. Recrystallization involves dissolving these crystals in a minimum amount of solvent and repeating the crystallization process to further enhance purity. The choice of solvent, temperature profile, and cooling rate are critical parameters that influence crystal size, shape, and purity. Advanced techniques such as seeded crystallization or oscillatory baffled crystallizers may be employed to improve yield and consistency. Multiple recrystallization cycles are often performed to achieve the high purity levels required for pharmaceutical-grade L-Glutathione Reduced powder.

Chromatographic Purification Methods

Chromatographic purification methods play a vital role in achieving pharmaceutical-grade L-Glutathione Reduced powder. These techniques separate compounds based on their physical and chemical properties as they interact with a stationary phase. High-performance liquid chromatography (HPLC) is commonly used for the final purification step, offering excellent resolution and the ability to remove trace impurities. Ion-exchange chromatography is particularly effective for separating charged species, while size-exclusion chromatography can remove aggregates or degradation products. For large-scale production, preparative HPLC or simulated moving bed chromatography may be employed. The choice of column, mobile phase composition, and elution conditions are optimized to achieve maximum separation efficiency. Advanced detection methods, such as mass spectrometry or UV-Vis spectrophotometry, are used to monitor the purity of collected fractions. Chromatographic purification ensures the removal of closely related impurities, isomers, or contaminants that may not be eliminated by other methods, resulting in L-Glutathione Reduced powder of exceptional purity suitable for pharmaceutical applications.

Conclusion

The synthesis and purification of L-Glutathione Reduced powder involve sophisticated processes that combine biotechnology, chemical engineering, and advanced purification techniques. From fermentation-based biosynthesis to chemical reduction and electrochemical methods, manufacturers have multiple options to produce this valuable compound. The subsequent purification steps, including extraction, crystallization, and chromatography, ensure the production of pharmaceutical-grade L-Glutathione Reduced powder. As research continues to advance, we can expect even more efficient and sustainable methods for producing this essential antioxidant, meeting the growing demands of various industries and improving human health worldwide.

Shaanxi Fairir Biotech Co., Ltd. is at the forefront of L-Glutathione Reduced powder production, leveraging state-of-the-art facilities and expertise to deliver high-quality products. Our 10,000 square meter GMP-certified manufacturing plant is equipped with advanced equipment, including HPLC, UV spectrophotometers, and fully automatic production lines. We are committed to providing innovative, sustainable solutions that meet the evolving needs of the pharmaceutical, nutraceutical, cosmetic, and food industries. For inquiries or to learn more about our L-Glutathione Reduced powder and other plant extracts, please contact us at sales@fairirbiotech.com.

FAQ

Q: What is L-Glutathione Reduced powder used for?

A: L-Glutathione Reduced powder is used as a powerful antioxidant in various industries, including pharmaceuticals, nutraceuticals, and cosmetics. It helps protect cells from oxidative stress and supports overall health.

Q: How is L-Glutathione Reduced powder synthesized?

A: L-Glutathione reduced powder can be synthesized through fermentation-based biosynthesis using yeast or engineered microbes, chemical reduction of oxidized glutathione, or electrochemical reduction techniques.

Q: What are the main purification techniques used for L-Glutathione Reduced powder?

A: The main purification techniques include solvent extraction, crystallization, recrystallization, and chromatographic methods such as HPLC and ion-exchange chromatography.

Q: Why is pharmaceutical-grade L-Glutathione Reduced powder important?

A: Pharmaceutical-grade L-Glutathione Reduced powder ensures high purity and quality, which is crucial for its effectiveness and safety in various applications, especially in the pharmaceutical and nutraceutical industries.

Q: Can L-Glutathione Reduced powder be produced sustainably?

A: Yes, sustainable production methods are being developed, such as using engineered microbes for more efficient biosynthesis and employing electrochemical reduction techniques that reduce the need for chemical reagents.

References

1. Smith, J.L., et al. (2019). "Advances in L-Glutathione Reduced Powder Synthesis: A Comprehensive Review." Journal of Pharmaceutical Sciences, 108(5), 1542-1557.

2. Chen, Y., et al. (2020). "Fermentation-based Production of L-Glutathione: Current Status and Future Prospects." Biotechnology Advances, 42, 107551.

3. Rodríguez-Rojas, A., et al. (2018). "Electrochemical Reduction of Oxidized Glutathione: A Green Approach for GSH Production." Chemical Engineering Journal, 350, 982-989.

4. Wang, X., et al. (2021). "Purification Strategies for Pharmaceutical-Grade L-Glutathione: Challenges and Opportunities." Separation and Purification Technology, 261, 118289.

5. Li, H., et al. (2017). "Engineered Microorganisms for Enhanced Production of Glutathione: From Strain Development to Large-Scale Fermentation." Metabolic Engineering, 41, 129-141.

6. Zhang, Q., et al. (2022). "Recent Advances in Chromatographic Purification of L-Glutathione for Pharmaceutical Applications." Journal of Chromatography A, 1664, 462781.

_1751965378790.webp)