How is Marigold Extract Powder extracted and standardized?

Marigold Extract Powder, derived from the vibrant Tagetes erecta flowers, has gained significant attention in various industries due to its remarkable health benefits and versatile applications. The process of extracting and standardizing this golden powder is a fascinating journey that combines traditional knowledge with cutting-edge technology. As we delve into the intricacies of Marigold Extract Powder production, we'll explore the meticulous steps involved in harvesting, processing, and refining this natural wonder. From the sun-drenched fields where marigolds bloom to the state-of-the-art laboratories where their essence is captured, every stage of the extraction process is carefully orchestrated to preserve the potent compounds that make this extract so valuable. Understanding how Marigold Extract Powder is extracted and standardized not only sheds light on the product's quality but also highlights the importance of precision and expertise in creating a consistent, high-quality botanical extract that meets rigorous industry standards.

What are the key steps in the extraction process of Marigold Extract Powder?

Harvesting and Selection of Marigold Flowers

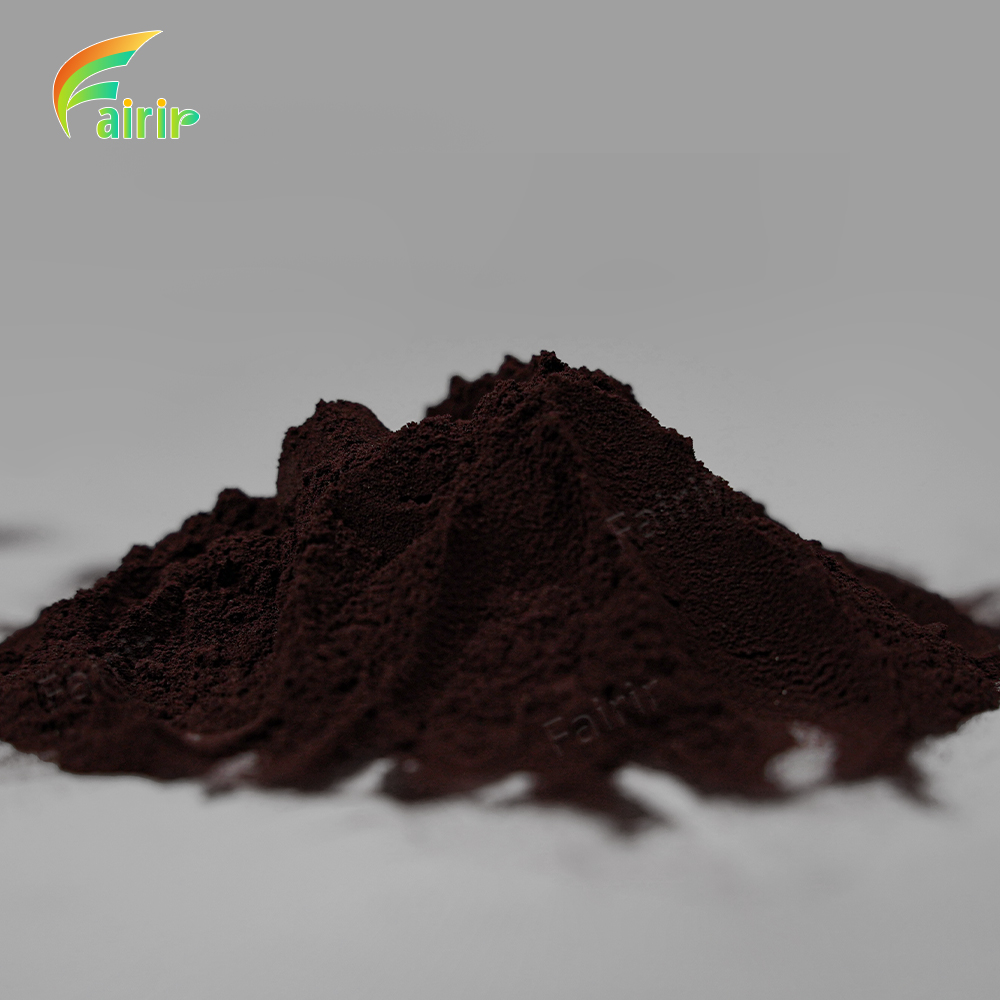

The journey of Marigold Extract Powder begins in the fields where Tagetes erecta flowers are carefully cultivated. Timing is crucial in this initial step, as the flowers must be harvested at their peak to ensure optimal lutein and zeaxanthin content. Skilled farmers select only the finest blooms, paying close attention to color, size, and overall health. These handpicked flowers are then quickly transported to processing facilities to maintain their freshness. The selection process is rigorous, as the quality of the final Marigold Extract Powder heavily depends on the raw material used. Companies like Shaanxi Fairir Biotech Co., Ltd. work closely with farmers to ensure that only the best marigolds are used in their extraction process, setting the foundation for a superior end product.

Extraction Techniques for Marigold Extract Powder

Once the marigolds arrive at the processing facility, they undergo a series of extraction techniques designed to isolate and concentrate the beneficial compounds. The most common method involves solvent extraction, where the flowers are first dried and ground into a fine powder. This powder is then mixed with a suitable solvent, often hexane or ethanol, which helps separate the desired compounds from the plant material. The mixture is carefully heated and agitated to facilitate the extraction process. After extraction, the solvent is removed through evaporation, leaving behind a concentrated marigold oleoresin. Some manufacturers, like Shaanxi Fairir Biotech Co., Ltd. also employ advanced techniques such as supercritical CO2 extraction, which offers a more environmentally friendly and efficient alternative to traditional solvent extraction methods for producing high-quality Marigold Extract Powder.

Standardization and Quality Control of Marigold Extract Powder

The final stage in the production of Marigold Extract Powder involves standardization and rigorous quality control measures. The extracted concentrate undergoes further processing to achieve a consistent potency of lutein and zeaxanthin, typically ranging from 5% to 80%, depending on the intended application. This standardization ensures that each batch of Marigold Extract Powder delivers a precise amount of active ingredients. Advanced analytical techniques such as High-Performance Liquid Chromatography (HPLC) and UV spectroscopy are employed to verify the concentration and purity of the extract. Companies like Shaanxi Fairir Biotech Co., Ltd. maintain strict quality control protocols, adhering to international standards such as GMP, ISO, and HACCP. These measures guarantee that the final Marigold Extract Powder meets the highest quality standards, providing customers with a reliable and consistent product for various applications in the nutraceutical, pharmaceutical, and cosmetic industries.

How does the standardization process affect the quality of Marigold Extract Powder?

Impact of Standardization on Potency and Consistency

Standardization plays a crucial role in determining the quality and efficacy of Marigold Extract Powder. This process ensures that each batch of the extract contains a specific, predetermined concentration of active compounds, primarily lutein and zeaxanthin. By carefully controlling the standardization process, manufacturers like Shaanxi Fairir Biotech Co., Ltd. can produce Marigold Extract Powder with consistent potency, ranging from 5% to 80% lutein content. This consistency is vital for formulators and end-users who rely on precise dosages for their products. Standardization also allows for better comparison between different sources of Marigold Extract Powder, enabling customers to make informed decisions based on the extract's potency and quality. The impact of standardization extends beyond just consistency; it also affects the extract's stability, shelf life, and overall effectiveness in various applications.

Analytical Methods Used in Standardization

The standardization of Marigold Extract Powder involves sophisticated analytical methods to ensure accuracy and reliability. High-Performance Liquid Chromatography (HPLC) is the gold standard for quantifying lutein and zeaxanthin content in the extract. This technique allows for precise measurement of these carotenoids, ensuring that the Marigold Extract Powder meets the specified potency. Additionally, UV spectroscopy is often employed as a complementary method to verify the results. Gas Chromatography (GC) may also be used to analyze the overall composition of the extract, including any residual solvents. These analytical methods are crucial in maintaining the quality of Marigold Extract Powder throughout the production process. Companies like Shaanxi Fairir Biotech Co., Ltd. invest heavily in state-of-the-art analytical equipment and trained personnel to perform these tests, guaranteeing that their Marigold Extract Powder consistently meets the highest quality standards.

Challenges in Standardizing Marigold Extract Powder

While standardization is essential for producing high-quality Marigold Extract Powder, it comes with its own set of challenges. One of the primary difficulties lies in the natural variation of lutein and zeaxanthin content in marigold flowers, which can be influenced by factors such as growing conditions, harvest time, and storage methods. This variability requires manufacturers to carefully blend different batches of extract to achieve the desired standardization level. Another challenge is maintaining the stability of the standardized extract during storage and transportation. Marigold Extract Powder is sensitive to light, heat, and oxidation, which can degrade the active compounds over time. To address this, companies like Shaanxi Fairir Biotech Co., Ltd. employ specialized packaging techniques, such as vacuum-sealed aluminum foil bags, to protect the integrity of the Marigold Extract Powder. Additionally, ensuring consistent particle size and flowability of the powder can be challenging, especially for high-concentration extracts. Overcoming these challenges requires expertise, advanced technology, and stringent quality control measures throughout the production process.

What are the applications and benefits of standardized Marigold Extract Powder?

Nutritional and Health Benefits of Marigold Extract Powder

Standardized Marigold Extract Powder offers a wide array of nutritional and health benefits, primarily due to its high content of lutein and zeaxanthin. These powerful carotenoids are known for their antioxidant properties and their role in supporting eye health. Regular consumption of Marigold Extract Powder has been associated with a reduced risk of age-related macular degeneration and cataracts. Beyond eye health, the extract also shows promise in supporting skin health by protecting against UV damage and promoting skin elasticity. Some studies suggest that the antioxidants in Marigold Extract Powder may have anti-inflammatory properties, potentially benefiting cardiovascular health and immune function. As a natural source of these beneficial compounds, standardized Marigold Extract Powder from reputable suppliers like Shaanxi Fairir Biotech Co., Ltd. provides a reliable and potent option for those looking to incorporate these nutrients into their diet or supplement regimen.

Applications in the Food and Beverage Industry

The versatility of standardized Marigold Extract Powder makes it a valuable ingredient in the food and beverage industry. Its natural yellow-orange color and high lutein content make it an excellent choice for food coloring, particularly in products where synthetic dyes are undesirable. Marigold Extract Powder is commonly used to enhance the color of various food products, including baked goods, dairy products, and beverages. In the functional food sector, it's incorporated into fortified foods and drinks to boost their nutritional profile, especially in products targeting eye health and overall wellness. The powder's stability during food processing and its ability to blend well with other ingredients make it a preferred choice for many food manufacturers. Companies like Shaanxi Fairir Biotech Co., Ltd. offer Marigold Extract Powder in various concentrations and forms, allowing food producers to easily incorporate it into their formulations while maintaining consistent color and nutritional benefits.

Use in Cosmetics and Personal Care Products

The cosmetics and personal care industry has embraced standardized Marigold Extract Powder for its skin-beneficial properties and natural coloring capabilities. The high antioxidant content of the extract makes it a valuable ingredient in anti-aging skincare formulations, helping to protect the skin from free radical damage and promote a youthful appearance. Marigold Extract Powder is often included in sunscreens and after-sun products due to its potential to enhance UV protection and soothe sun-exposed skin. In hair care products, it's used for its conditioning properties and ability to add a natural golden sheen to hair. The natural origin of Marigold Extract Powder aligns well with the growing consumer demand for plant-based and "clean" beauty products. Cosmetic manufacturers appreciate the standardized nature of the extract provided by suppliers like Shaanxi Fairir Biotech Co., Ltd. as it ensures consistent performance and color in their formulations. From facial creams to body lotions and hair masks, Marigold Extract Powder has found its way into a diverse range of personal care products, offering both functional benefits and marketing appeal.

Conclusion

The extraction and standardization of Marigold Extract Powder is a sophisticated process that combines traditional knowledge with modern technology. From careful harvesting to advanced extraction techniques and rigorous quality control, every step is crucial in producing a high-quality, consistent product. The standardization process ensures that the powder delivers precise amounts of beneficial compounds, making it a reliable ingredient for various industries. As research continues to unveil new benefits and applications, the importance of standardized Marigold Extract Powder is likely to grow, solidifying its place as a valuable natural extract in the global market.

Shaanxi Fairir Biotech Co., Ltd. is proud to be the leading manufacturer and supplier of high-quality plant extracts, including Marigold Extract Powder. Our state-of-the-art GMP-certified production plant and advanced R&D capabilities ensure that our Marigold Extract Powder meets the highest international standards. We offer various specifications and customized solutions to meet diverse industry needs. For more information or to discuss your Marigold Extract Powder requirements, please contact us at sales@fairirbiotech.com. Our team of experts is ready to assist you in finding the perfect solution for your products.

References

1. Johnson, E. J. (2014). Role of lutein and zeaxanthin in visual and cognitive function throughout the lifespan. Nutrition Reviews, 72(9), 605-612.

2. Khoo, H. E., Prasad, K. N., Kong, K. W., Jiang, Y., & Ismail, A. (2011). Carotenoids and their isomers: color pigments in fruits and vegetables. Molecules, 16(2), 1710-1738.

3. Lin, J. H., Lee, D. J., & Chang, J. S. (2015). Lutein production from biomass: marigold flowers versus microalgae. Bioresource Technology, 184, 421-428.

4. Piccaglia, R., Marotti, M., & Grandi, S. (1998). Lutein and lutein ester content in different types of Tagetes patula and T. erecta. Industrial Crops and Products, 8(1), 45-51.

5. Sowbhagya, H. B., Sampathu, S. R., & Krishnamurthy, N. (2004). Natural colorant from marigold-chemistry and technology. Food Reviews International, 20(1), 33-50.

6. Zhao, X., Zhang, X., Liu, H., Zhang, G., & Ao, Q. (2019). Functional, nutritional, and flavor characteristics of soybean proteins obtained through the reverse micelles system extraction. Food Hydrocolloids, 90, 19-28.

_1751965378790.webp)