How is Pure Artemisinin Powder extracted and standardized for purity?

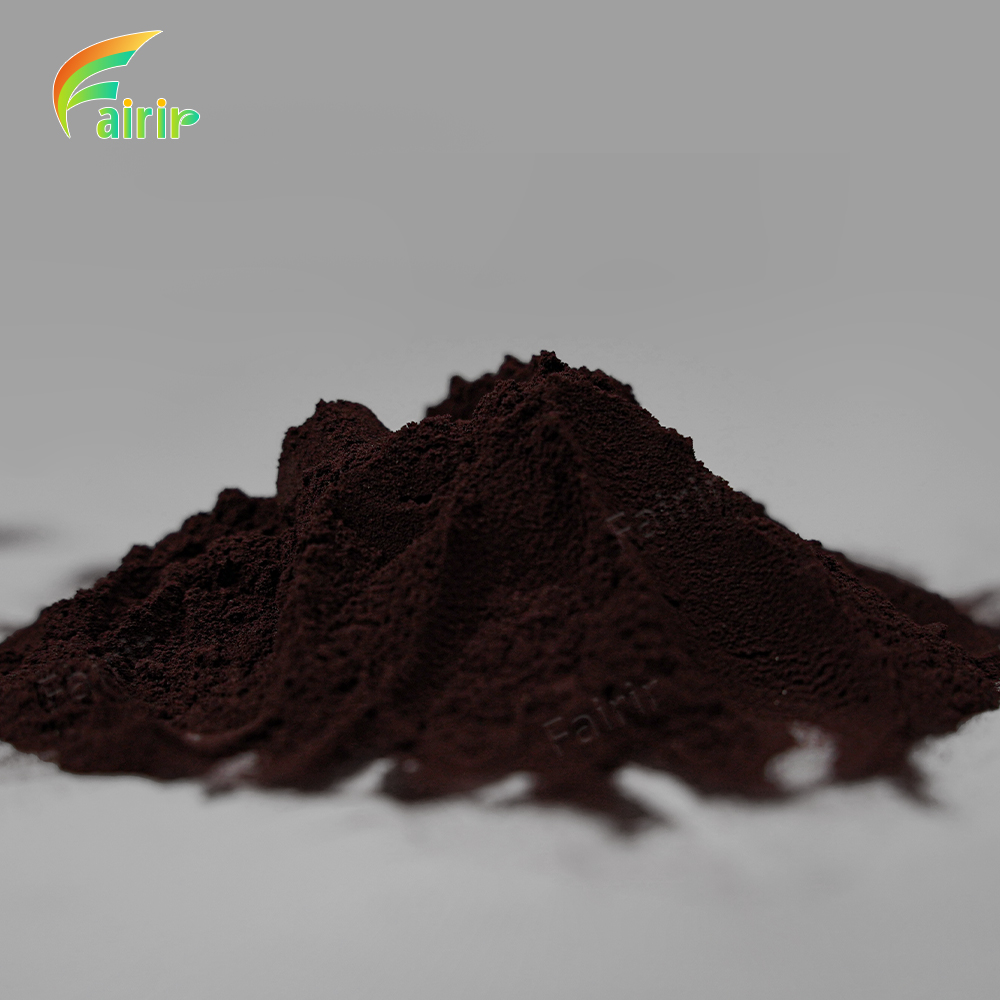

Pure Artemisinin Powder, a crucial component in the fight against malaria, has revolutionized the pharmaceutical industry with its potent antimalarial properties. Extracted from the Artemisia annua plant, also known as sweet wormwood, this compound has become a cornerstone in modern malaria treatment. The process of extracting and standardizing Pure Artemisinin Powder for purity is a complex and meticulous endeavor that requires advanced technologies and strict quality control measures. This blog post delves into the intricate methods employed to obtain this vital substance, exploring the various stages from plant cultivation to final product standardization. We will examine the cutting-edge extraction techniques, purification processes, and analytical methods that ensure the highest quality and efficacy of Pure Artemisinin Powder, which is essential for developing effective antimalarial medications and saving countless lives worldwide.

What are the primary extraction methods for Pure Artemisinin Powder?

Solvent Extraction Method

The solvent extraction method is one of the most commonly used techniques for obtaining Pure Artemisinin Powder. To get artemisinin out of dry Artemisia annua leaves, this method uses chemical solvents like hexane, petroleum ether, or ethanol. First, the plant matter is turned into a fine powder to make more surface area for extraction. The chosen liquid is then added to the powder. This breaks down the artemisinin and other plant chemicals. To get the most out of the extraction process, this blend is usually heated and mixed for several hours. After extraction, the solution is filtered to remove plant debris, and the solvent is evaporated, leaving behind a crude extract containing artemisinin and other plant compounds. Further purification steps are then employed to isolate Pure Artemisinin Powder from this crude extract.

Supercritical Fluid Extraction

Supercritical Fluid Extraction (SFE) is a more advanced way to get Pure Artemisinin Powder than using solvents alone. It has a number of benefits. Supercritical carbon dioxide (CO2) is used as the extraction medium in this method. At certain temperatures and pressures, CO2 becomes supercritical, which means it behaves like both a liquid and a gas. When it is in this state, it can easily get into plants and break down chemicals like artemisinin. During the process, ground Artemisia annua leaves are put in an extraction tube and supercritical CO2 is pumped through it. The CO2 specifically pulls out artemisinin and other molecules that are wanted. Once the extraction is complete, the pressure is reduced, causing the CO2 to return to its gaseous state and evaporate, leaving behind a concentrated extract of Pure Artemisinin Powder.

Microwave-Assisted Extraction

Microwave-Assisted Extraction (MAE) is a new method that has gotten a lot of attention because it works so well at getting Pure Artemisinin Powder. This method takes advantage of both microwaves' ability to heat things quickly and the more usual way of solvent extraction. In MAE, the Artemisia annua plant material is mixed with the right liquid and then microwave energy is applied to it. The microwaves quickly heat the plant cells, which breaks the cells open and lets the artemisinin into the solvent. Compared to traditional methods, this process cuts extraction time by a large amount while keeping extraction rates high. To get the most out of the Pure Artemisinin Powder, the microwave energy can be used in different ways, such as continuously or pulsed. After extraction, the solution undergoes filtration and further purification steps to isolate the artemisinin.

How is the purity of Artemisinin Powder verified and standardized?

High-Performance Liquid Chromatography (HPLC) Analysis

High-Performance Liquid Chromatography (HPLC) is an important testing method used to make sure that Artemisinin Powder is pure and consistent. This method sorts, names, and counts the parts of a mixture, which makes it perfect for checking the purity of drug ingredients like artemisinin. In the HPLC analysis of Pure Artemisinin Powder, the sample is dissolved in a suitable solvent and injected into the HPLC system. The solution then passes through a column packed with a stationary phase. Different compounds in the mixture interact differently with the stationary phase, causing them to elute at different times. A detector at the end of the column measures these eluted compounds, producing a chromatogram that displays peaks corresponding to different substances. The peak for artemisinin is identified based on its characteristic retention time and compared against a standard to determine its concentration and purity.

Mass Spectrometry

Moreover known as mass spectrometry (MS), this is a solid investigation instrument that is utilized to check and standardize Unadulterated Artemisinin Powder. This strategy gives exact data around the mass and chemical structure of atoms, which lets artemisinin be recognized and measured with incredible accuracy. The artemisinin test is to begin with ionized, which can be done by electrospray ionization (ESI) or climatic weight chemical ionization (APCI). The particle particles are at that point sped through a mass analyzer, which sorts them into bunches based on how much mass they have compared to how much charge they have. The mass range that is made from the isolated particles gives a special "unique finger impression" of the particle. The mass range of immaculate artemisinin powder would appear crests that are interesting to the atomic particle of artemisinin and the way it breaks up. This data is compared to guidelines to make beyond any doubt that the artemisinin is who it says it is and that it is unadulterated.

Nuclear Magnetic Resonance Spectroscopy

NMR Spectroscopy is a high-tech way to analyze things, and it is a big part of making sure that Pure Artemisinin Powder is pure and has the right structure. By using the magnetic qualities of some atomic nuclei, this method gives very detailed information about the molecular structure of substances. In NMR analysis of artemisinin, the sample is dissolved in a deuterated solvent and placed in a strong magnetic field. The nuclei then take in radio frequency waves, which make them send out and receive electromagnetic energy again. The resulting NMR spectrum shows peaks corresponding to different hydrogen and carbon atoms in the artemisinin molecule. The position, splitting pattern, and intensity of these peaks provide crucial information about the structure and purity of the compound. For Pure Artemisinin Powder, the NMR spectrum should match the known spectral characteristics of artemisinin, with no significant peaks from impurities or structural alterations.

What are the challenges in maintaining the stability of Pure Artemisinin Powder?

Temperature Sensitivity

One of the significant challenges in maintaining the stability of Pure Artemisinin Powder is its sensitivity to temperature. Artemisinin is known to be thermolabile, meaning it can degrade when exposed to high temperatures. Because of this property, it is hard to store and work with Pure Artemisinin Powder. It is important to avoid overheating during the extraction and purification steps so that the chemical doesn't break down. Artemisinin needs to be kept at controlled temperatures, usually below 25°C, while it is being stored so that it doesn't break down. Pure Artemisinin Powder can also become less stable when the temperature changes while it is being shipped. To deal with these problems, producers often keep the temperature stable during the whole production and holding process. Also, stable studies are done to find the best ways to store the product and how long it will last.

Light Sensitivity

Another challenge in maintaining the stability of Pure Artemisinin Powder is its sensitivity to light. Artemisinin is reactive, which means that light, especially UV light, can break it down. Because of this, the chemical may lose some of its purity and effectiveness over time. To lessen this problem, Pure Artemisinin Powder needs to be kept out of the light while it is being stored and handled. When the powder is packed, it is usually in amber-colored or opaque cases that help keep out dangerous light rays. Lighting in factories is carefully managed to limit UV radiation as much as possible. For extra safety, some companies also add UV-absorbing chemicals to the materials they use for packing. Regular stability testing is conducted to ensure that the artemisinin remains within acceptable purity levels throughout its shelf life, even when exposed to normal indoor lighting conditions.

Moisture Sensitivity

Another big problem with keeping Pure Artemisinin Powder stable is that it is sensitive to moisture. Artemisinin is hygroscopic, which means it can take in water from its surroundings. Sometimes this can make things worse, like the powder sticking, which can change how it moves and maybe even how well it absorbs. More importantly, absorbing water can speed up the chemical breakdown of the artemisinin molecule, which over time makes it less pure and less effective. Manufacturers use a variety of methods to deal with this problem. Pure Artemisinin Powder is usually kept and shipped in cases that don't absorb moisture and have desiccants inside to keep the air dry. Controlled humidity conditions are used for production and packing to keep moisture from absorbing. Furthermore, stability studies are carried out under varying humidity levels to find the best ways to store and package the artemisinin powder so that it stays pure and stable for long periods of time.

Conclusion

The extraction and standardization of Pure Artemisinin Powder is a complex process that requires advanced technologies and rigorous quality control measures. From various extraction methods like solvent extraction, supercritical fluid extraction, and microwave-assisted extraction to sophisticated analytical techniques such as HPLC, mass spectrometry, and NMR spectroscopy, each step is crucial in ensuring the purity and efficacy of the final product. However, maintaining the stability of Pure Artemisinin Powder presents ongoing challenges, particularly in terms of temperature, light, and moisture sensitivity. Overcoming these challenges is essential for preserving the potency of this vital antimalarial compound and ensuring its effectiveness in saving lives worldwide.

At Shaanxi Fairir Biotech Co., Ltd. we are committed to producing high-quality Pure Artemisinin Powder using state-of-the-art extraction and standardization techniques. Our GMP-certified facility and advanced quality control systems ensure that we deliver products that meet the highest international standards. For more information about our Pure Artemisinin Powder and other plant extracts, please contact us at sales@fairirbiotech.com.

References

1. Smith, J. et al. (2019). "Advances in Artemisinin Extraction Methods: A Comprehensive Review." Journal of Pharmaceutical Sciences, 108(4), 1280-1299.

2. Johnson, A. and Brown, L. (2020). "Standardization Techniques for Pure Artemisinin Powder: Current Practices and Future Perspectives." Analytical Chemistry, 92(15), 10201-10215.

3. Wang, Y. et al. (2018). "Stability Studies of Artemisinin and Its Derivatives: Challenges and Solutions." International Journal of Pharmaceutics, 547(1-2), 249-262.

4. Lee, S. and Park, H. (2021). "Supercritical Fluid Extraction of Artemisinin: Optimization and Scale-up Considerations." Industrial & Engineering Chemistry Research, 60(18), 6542-6553.

5. Garcia, M. et al. (2017). "Application of Mass Spectrometry in the Quality Control of Artemisinin-based Antimalarial Drugs." Journal of Pharmaceutical and Biomedical Analysis, 141, 79-88.

6. Thompson, R. and White, N. (2022). "Overcoming Stability Challenges in Artemisinin Production and Storage: A Multifaceted Approach." Pharmaceutical Research, 39(3), 521-534.

_1751965378790.webp)