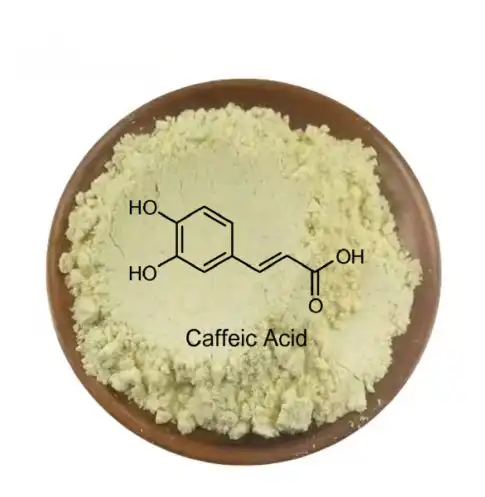

Caffeic acid powder environmental sources and sustainability

Caffeic acid powder, a potent antioxidant compound found naturally in various plant sources, has gained significant attention in recent years due to its numerous health benefits and potential applications across multiple industries. As the demand for this versatile substance continues to grow, it becomes increasingly important to explore sustainable sources and environmentally friendly production methods. This blog delves into the environmental sources of caffeic acid powder, examining innovative extraction techniques from agricultural byproducts and discussing the challenges and solutions associated with its sustainable production. By understanding the environmental impact and exploring eco-friendly approaches, we can ensure a more sustainable future for caffeic acid powder production while meeting the rising global demand for this valuable compound.

Exploring Olive Mill Wastewater as a Rich Source of Caffeic Acid

Characterization of Olive Mill Wastewater

Olive mill wastewater (OMW) has emerged as a promising source of caffeic acid powder, offering a sustainable solution to the environmental challenges posed by this agricultural byproduct. OMW is rich in phenolic compounds, including caffeic acid, which can be extracted and purified for various applications. The characterization of OMW reveals a complex mixture of organic matter, suspended solids, and polyphenols, with caffeic acid being one of the most abundant phenolic compounds present. By utilizing advanced analytical techniques such as HPLC and mass spectrometry, researchers have been able to quantify the caffeic acid content in OMW, typically ranging from 50 to 200 mg/L. This high concentration makes OMW an attractive source for caffeic acid powder production, offering a sustainable alternative to traditional extraction methods from plant materials.

Extraction Techniques for Caffeic Acid from OMW

The extraction of caffeic acid powder from olive mill wastewater requires innovative techniques to ensure high yields and purity. Several methods have been developed to efficiently isolate caffeic acid from OMW, including liquid-liquid extraction, solid-phase extraction, and membrane filtration. Among these, liquid-liquid extraction using ethyl acetate has shown promising results, with recovery rates of up to 80% for caffeic acid. Additionally, advanced technologies such as supercritical fluid extraction and ultrasound-assisted extraction have been explored to enhance the efficiency and sustainability of the process. These methods not only improve the yield of caffeic acid powder but also reduce the environmental impact by minimizing solvent usage and energy consumption. The extracted caffeic acid can then be purified and crystallized to obtain high-quality caffeic acid powder suitable for various applications in the pharmaceutical, nutraceutical, and cosmetic industries.

Environmental Benefits of Utilizing OMW

The utilization of olive mill wastewater for caffeic acid powder production offers significant environmental benefits. By repurposing this agricultural waste stream, we can reduce the environmental burden associated with OMW disposal while simultaneously creating a valuable product. The extraction of caffeic acid from OMW helps to mitigate the pollution potential of this waste, as the phenolic compounds are removed before the treated water is released into the environment. Moreover, this approach aligns with circular economy principles, transforming a waste product into a high-value resource. The production of caffeic acid powder from OMW also reduces the need for cultivating dedicated crops for caffeic acid extraction, thereby conserving land and water resources. As sustainability becomes increasingly important in industrial processes, the use of OMW as a source of caffeic acid powder represents a forward-thinking solution that addresses both waste management and resource efficiency challenges.

Sustainable Extraction Methods for Caffeic Acid from Agro-Industrial Byproducts

Green Solvents and Eco-Friendly Extraction Processes

The quest for sustainable extraction methods for caffeic acid powder has led to the development of green solvents and eco-friendly processes. Traditional extraction methods often rely on petroleum-based solvents, which pose environmental and health risks. In contrast, green solvents such as deep eutectic solvents (DES) and bio-based solvents offer a more sustainable alternative. These solvents are biodegradable, non-toxic, and can be derived from renewable resources. For instance, choline chloride-based DES has shown excellent efficiency in extracting caffeic acid from various plant materials, including agro-industrial byproducts. Additionally, supercritical CO2 extraction has emerged as a clean and efficient method for isolating caffeic acid powder, leaving no solvent residues in the final product. These green extraction techniques not only reduce the environmental footprint of caffeic acid production but also enhance the purity and quality of the extracted compound, meeting the stringent standards required by the pharmaceutical and nutraceutical industries.

Valorization of Coffee and Tea Waste

Coffee and tea waste represent abundant and underutilized sources of caffeic acid powder. These byproducts, generated in massive quantities worldwide, contain significant amounts of phenolic compounds, including caffeic acid. Innovative extraction methods have been developed to valorize these waste streams, turning them into valuable resources for caffeic acid production. For instance, subcritical water extraction has shown promising results in isolating caffeic acid from spent coffee grounds, achieving high yields with minimal environmental impact. Similarly, microwave-assisted extraction techniques have been employed to extract caffeic acid from tea waste, offering a rapid and energy-efficient alternative to conventional methods. By repurposing these agro-industrial byproducts, we can create a circular economy model for caffeic acid powder production, reducing waste and maximizing resource efficiency. The extracted caffeic acid powder can then be utilized in various applications, from antioxidant supplements to natural preservatives in the food industry.

Enzyme-Assisted Extraction Technologies

Enzyme-assisted extraction represents a cutting-edge approach to sustainable caffeic acid powder production from agro-industrial byproducts. This method employs specific enzymes to break down plant cell walls, facilitating the release of caffeic acid and other phenolic compounds. Enzymes such as cellulases, pectinases, and hemicellulases are commonly used in this process, offering a gentle and efficient extraction method that preserves the integrity of the target compounds. The enzyme-assisted extraction of caffeic acid powder has shown remarkable results in terms of yield and purity, often surpassing traditional solvent-based methods. Moreover, this technique operates under mild conditions, requiring less energy and reducing the need for harsh chemicals. The eco-friendly nature of enzyme-assisted extraction aligns perfectly with the growing demand for sustainable production methods in the nutraceutical and pharmaceutical industries. As research in this field progresses, we can expect further optimizations and scale-up of enzyme-assisted extraction technologies, paving the way for more sustainable and efficient caffeic acid powder production from a wide range of agricultural residues.

Environmental Impact of Caffeic Acid Production: Challenges and Solutions

Life Cycle Assessment of Caffeic Acid Powder Production

Conducting a comprehensive life cycle assessment (LCA) of caffeic acid powder production is crucial for understanding and mitigating its environmental impact. The LCA encompasses all stages of production, from raw material sourcing to final product distribution, providing valuable insights into the carbon footprint, water usage, and overall ecological impact of caffeic acid powder manufacturing. Studies have shown that traditional extraction methods can be resource-intensive, particularly in terms of energy consumption and solvent usage. However, by implementing sustainable practices such as using renewable energy sources and adopting closed-loop solvent recovery systems, the environmental footprint of caffeic acid powder production can be significantly reduced. Additionally, the choice of raw materials plays a critical role in the overall sustainability of the process. Utilizing agricultural byproducts and waste streams as sources of caffeic acid not only reduces waste but also minimizes the need for dedicated crop cultivation, thereby conserving land and water resources.

Water Management and Pollution Control in Extraction Processes

Effective water management and pollution control are paramount in sustainable caffeic acid powder production. The extraction process often requires significant amounts of water, and the resulting wastewater can contain high levels of organic compounds and residual solvents. To address these challenges, innovative water treatment technologies have been developed, including advanced oxidation processes and membrane filtration systems. These technologies enable the removal of pollutants and the recycling of water within the production process, significantly reducing water consumption and minimizing environmental impact. Moreover, the implementation of zero-liquid discharge (ZLD) systems in caffeic acid powder production facilities represents a promising solution for water conservation and pollution prevention. ZLD systems treat and recycle all wastewater, eliminating the need for discharge and ensuring compliance with stringent environmental regulations. By adopting these advanced water management strategies, manufacturers can significantly improve the sustainability of caffeic acid powder production while meeting the growing demand for this valuable compound.

Energy Efficiency and Carbon Footprint Reduction

Improving energy efficiency and reducing the carbon footprint of caffeic acid powder production are critical steps towards sustainable manufacturing. Traditional extraction and purification processes often require significant energy inputs, contributing to greenhouse gas emissions. To address this, innovative technologies such as microwave-assisted extraction and ultrasound-assisted extraction have been developed, offering reduced processing times and lower energy consumption compared to conventional methods. These technologies not only improve the efficiency of caffeic acid powder production but also contribute to a substantial reduction in carbon emissions. Additionally, the integration of renewable energy sources, such as solar and wind power, into production facilities can further decrease the carbon footprint of caffeic acid manufacturing. Some companies have also implemented heat recovery systems and energy-efficient equipment to optimize energy usage throughout the production process. By focusing on energy efficiency and adopting cleaner energy sources, the caffeic acid powder industry can significantly reduce its environmental impact while maintaining high product quality and meeting the growing global demand for this versatile compound.

Conclusion

The sustainable production of caffeic acid powder presents both challenges and opportunities for the nutraceutical and pharmaceutical industries. By exploring innovative sources like olive mill wastewater and agro-industrial byproducts, implementing green extraction technologies, and focusing on environmental impact reduction, we can ensure a more sustainable future for caffeic acid production. The adoption of life cycle assessments, water management strategies, and energy-efficient practices will be crucial in minimizing the ecological footprint of caffeic acid powder manufacturing. As the industry continues to evolve, these sustainable approaches will not only meet the growing demand for caffeic acid but also contribute to a more circular and environmentally responsible economy.

At Shaanxi Fairir Biotech Co., Ltd. we are committed to leading the way in sustainable caffeic acid powder production. Our state-of-the-art 10,000 square meter GMP-certified facility in Xi'an City, Shaanxi Province, is equipped with cutting-edge technology to ensure the highest quality and purity of our products. We employ advanced extraction methods and rigorous quality control measures to deliver premium caffeic acid powder that meets global standards. Our team of experienced professionals is dedicated to innovation and sustainability, continuously exploring new ways to improve our processes and reduce our environmental impact. For inquiries about our caffeic acid powder or other plant extracts, please contact us at sales@fairirbiotech.com. We look forward to partnering with you to meet your nutraceutical and pharmaceutical needs with our sustainable and high-quality products.

FAQ

Q: What is caffeic acid powder used for?

A: Caffeic acid powder is used as an antioxidant in dietary supplements, cosmetics, and pharmaceuticals. It has anti-inflammatory properties and potential applications in cancer prevention and skin protection.

Q: How is caffeic acid powder sustainably sourced?

A: Sustainable sources include olive mill wastewater, coffee and tea waste, and other agro-industrial byproducts. Green extraction methods such as supercritical CO2 extraction and enzyme-assisted extraction are used to minimize environmental impact.

Q: What are the environmental benefits of using olive mill wastewater for caffeic acid extraction?

A: Utilizing olive mill wastewater reduces waste, mitigates pollution, and creates a valuable product from a byproduct, aligning with circular economy principles and conserving resources.

Q: How does enzyme-assisted extraction improve caffeic acid powder production?

A: Enzyme-assisted extraction offers gentler processing conditions, higher yields, and improved purity while reducing energy consumption and the need for harsh chemicals.

Q: What measures are taken to reduce the carbon footprint of caffeic acid powder production?

A: Measures include implementing energy-efficient technologies, using renewable energy sources, and adopting microwave and ultrasound-assisted extraction methods to reduce processing times and energy consumption.

References

1. Romani, A., et al. (2017). Sustainable production of caffeic acid from olive mill wastewater. Journal of Cleaner Production, 168, 1217-1223.

2. Chemat, F., et al. (2019). Green extraction of natural products: Concept and principles. International Journal of Molecular Sciences, 20(14), 3398.

3. Arabi, M., et al. (2020). Enzyme-assisted extraction of phenolic compounds from olive leaves: Characterization and application in functional foods. Process Biochemistry, 98, 198-209.

4. Lores, M., et al. (2018). Natural antioxidants from residual sources. Molecules, 23(10), 2624.

5. Galanakis, C.M. (2020). The Food Systems in the Era of the Coronavirus (COVID-19) Pandemic Crisis. Foods, 9(4), 523.

6. Pinto, D., et al. (2021). Valorization of olive mill wastewaters: From problems to opportunities. Processes, 9(8), 1236.

_1751965378790.webp)