How to Choose the Best Pure Glucomannan Powder?

Selecting the optimal Pure Glucomannan Powder requires careful evaluation of purity levels, manufacturing standards, and supplier credentials. This natural water-soluble dietary fiber, derived from konjac root (Amorphophallus konjac), serves diverse applications across pharmaceutical, nutraceutical, and food industries. Quality glucomannan powder should meet specifications of 85-95% purity, undergo rigorous testing via HPLC and UV spectrophotometry, and originate from GMP-certified facilities. Procurement professionals must assess supplier reliability, regulatory compliance, and customization capabilities to ensure consistent supply chain performance and end-product efficacy.

Understanding Pure Glucomannan Powder: Definition and Benefits

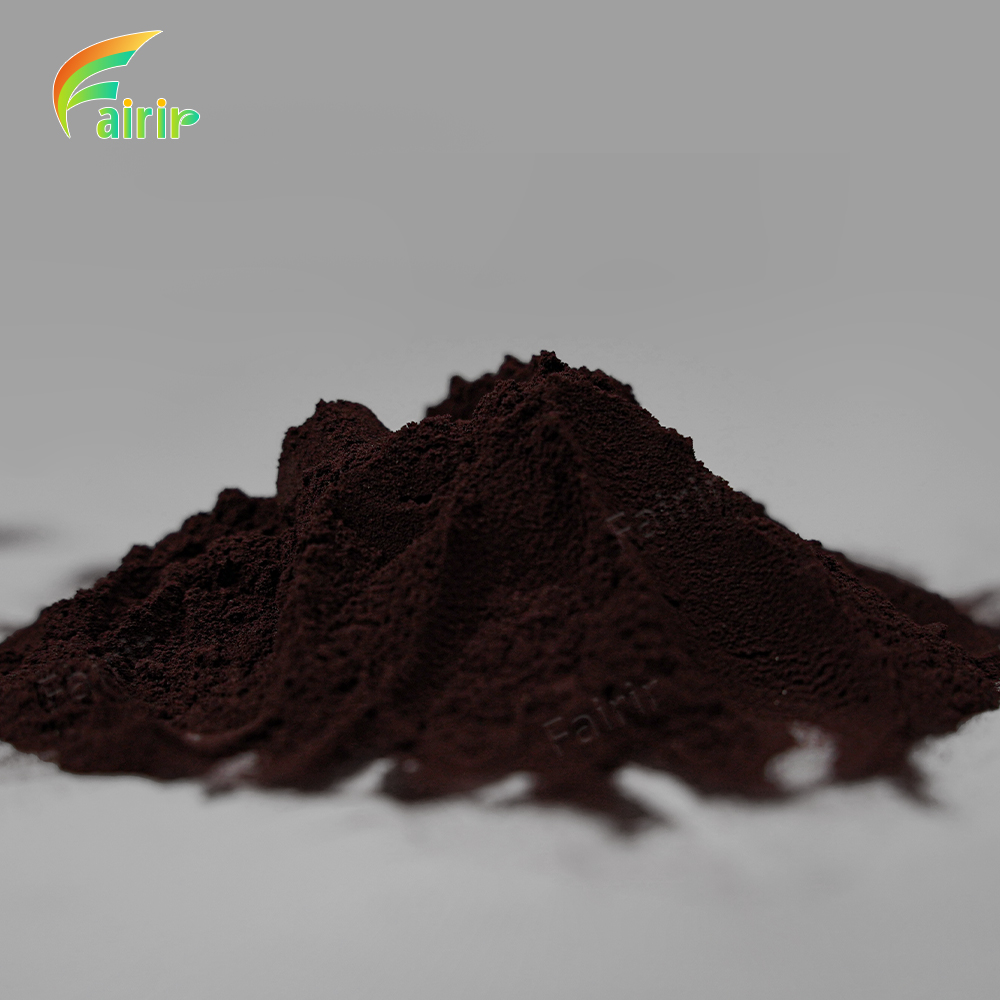

Pure glucomannan powder speaks to a premium-grade characteristic polysaccharide extracted through advanced preparation methods from konjac plant roots. This surprising dietary fiber illustrates uncommon water-absorption properties, growing up to 50 times its unique volume when hydrated. The fabrication process includes a cautious choice of premium konjac roots, followed by exact decontamination and concentration steps utilizing state-of-the-art splash drying technology.

Functional Properties and Applications

The atomic structure of glucomannan empowers special gel-forming characteristics that make it important over different businesses. In pharmaceutical applications, its capacity to moderate gastric purging underpins controlled-release definitions and craving management products. Nutraceutical producers use these properties for weight management supplements, whereas nourishment companies utilize their thickening capacities as a characteristic elective to engineered additives.

Research illustrates glucomannan's viability in blood sugar, making it especially profitable for diabetic product development. Clinical studies demonstrate critical changes in glycemic control when glucomannan is incorporated into dietary regimens. The fiber's prebiotic properties, moreover, back stomach related wellbeing, positioning it as a multifunctional ingredient for comprehensive wellness formulations.

Market Demand and Quality Standards

Global request for high-quality glucomannan proceeds extending as customer inclinations move toward natural, plant-based fixings. Producers looking for dependable supply sources prioritize items assembly worldwide quality guidelines counting ISO, GMP, and HACCP certifications. The flexibility of glucomannan applications—from conventional dietary supplements to inventive utilitarian foods—drives steady showcase development over different geographic regions.

Core Criteria for Selecting the Best Pure Glucomannan Powder

Distinguishing superior glucomannan powder requires understanding fundamental quality parameters that impact product performance and regulatory compliance. Purity levels represent the primary differentiating factor, with pharmaceutical-grade applications demanding 90-95% glucomannan content, while food-grade applications may accept 85-90% specifications.

Purity and Chemical Composition Analysis

Authentic Pure Glucomannan Powder ought to display an off-white to white powder appearance with a reliable molecule size distribution. Progressed explanatory testing strategies counting High-Performance Liquid Chromatography (HPLC), UV spectrophotometry, and Gas Chromatography (GC), give precise composition confirmation. These testing conventions guarantee items meet the indicated quality levels, while affirming the absence of destructive contaminants or adulterants.

The atomic weight profile essentially impacts utilitarian execution. High-molecular-weight glucomannan illustrates predominant consistency and gel-forming properties, basic for successful detailing execution. Trustworthy providers give comprehensive Certificates of Investigation (COA) reporting atomic weight dispersion, moisture content, and microbiological security parameters.

Organic Certification and Safety Profile

Organic-certified glucomannan powder requests to producers focusing on premium advertising portions emphasizing characteristic, economical ingredients. Natural certification guarantees development without engineered pesticides, herbicides, or hereditarily adjusted living beings. This certification includes esteem for brands situating items as clean-label choices in competitive markets.

Safety considerations include allergen testing, overwhelming metal investigation, and microbiological screening. Quality glucomannan ought to be naturally gluten-free, non-allergenic, and free from BSE/TSE defilement. Comprehensive security documentation underpins administrative endorsements over worldwide markets, decreasing compliance dangers for worldwide dissemination strategies.

Dosage Parameters and Functional Performance

Effective glucomannan dosing shifts altogether based on expected applications and target socioeconomics. Weight administration details ordinarily require 1-3 grams every day, whereas blood sugar control applications may utilize 0.5-1 gram doses. Understanding these parameters empowers exact detailing improvement and exact item labeling claims.

Functional execution testing assesses consistency advancement, gel quality, and soundness beneath different pH and temperature conditions. These characteristics specifically affect end-product execution and shopper fulfillment. Providers giving nitty-gritty utilitarian execution information empower producers to optimize definitions and anticipate item behavior all through rack life cycle.

Comparing Suppliers and Product Variants: What Global Buyers Should Know?

Supplier evaluation encompasses multiple criteria, including manufacturing capabilities, quality systems, and service responsiveness. Leading glucomannan manufacturers operate GMP-certified facilities equipped with advanced extraction and purification equipment. Manufacturing scale directly impacts pricing, availability, and supply chain reliability for long-term procurement relationships.

Manufacturing Capabilities and Quality Systems

Modern glucomannan generation requires modern hardware, including ceaseless countercurrent extraction frameworks, double-effect concentration hardware, and vacuum belt drying innovation. Facility utilizing these advanced frameworks accomplish higher quality levels and steady batch-to-batch quality. Generation capacity pointers incorporate extraction tank volumes, robotized generation lines, and by and large facility throughput capabilities.

Quality administration frameworks amplifying past fundamental GMP necessities illustrate provider commitment to excellence. ISO 9001 certification shows vigorous quality administration forms, whereas ISO 22000 certification addresses food safety management. HACCP usage guarantees efficient risk anticipation all through generation forms. These certifications collectively diminish risks of noncompliance and bolster administrative compliance over worldwide markets.

Product Format Options and Customization Services

Glucomannan accessibility ranges from numerous designs counting Pure Glucomannan Powder, typical items, and specialized definitions. Bulk powder offers the most extreme detailing adaptability for producers creating custom items. Pre-encapsulated alternatives give comfort for supplement companies looking for turnkey arrangements with decreased preparation requirements.

Private name fabricating administrations empower brands to use built up generation capabilities without considerable capital investment. These administrations regularly incorporate definition advancement, packaging plan, and administrative support. OEM organizations give versatile arrangements for companies encountering fast development or regular demand fluctuations.

Packaging alternatives run from laboratory-scale amounts for inquiry about applications to industrial-scale shipments for commercial generation. Standard bundling incorporates vacuum aluminum thwart sacks and fiber drums with double-layer food-grade poly pack liners. Custom bundling arrangements oblige particular capacity requirements and dealing with protocols.

Comparative Analysis with Alternative Fibers

Understanding glucomannan's preferences relative to elective dietary strands bolsters educated decision-making choices. Compared to psyllium husk, glucomannan illustrates a predominant water assimilation capacity and unbiased taste profile. These characteristics empower more flexible definition applications and move forward shopper recognition in packaged products.

Pectin and guar gum offer diverse utilitarian properties but need glucomannan's special combination of thick consistency and solidness over pH ranges. Methylcellulose gives comparative thickening properties but starts from engineered sources, constraining the request for common item positioning. These comparative bits of knowledge direct fabric choice based on particular detailing necessities and showcase positioning strategies.

Procurement Insights: How to Buy Pure Glucomannan Powder in Bulk?

Successful bulk procurement strategies begin with thorough supplier qualification and market analysis. Establishing relationships with multiple qualified suppliers ensures supply chain resilience while enabling competitive pricing negotiations. Market price benchmarks fluctuate based on raw material costs, seasonal availability, and global demand patterns.

Strategic Sourcing and Price Negotiations

Direct producer connections frequently give ideal estimating and supply stability compared to merchant agreements. Producers with coordinates supply chains from crude fabric sourcing through wrapped up item conveyance offer upgraded control and quality consistency. Long-term contracts stabilize estimating while ensuring supply accessibility amid peak demand periods.

Volume-based estimating levels compensate for larger amounts with decreased per-unit costs. Understanding the least arranged amounts and capacity necessities empowers ideal planning that balances stock costs with volume rebates. Installment terms arrangements can encourage optimize add up to taken a toll of possession through amplified installment periods or early installment discounts.

Logistics and Regulatory Compliance

International shipping requires careful consideration to traditions documentation, moment controls, and temperature-controlled transportation when vital. Lead times regularly run from 1-3 working days for in-stock materials, whereas custom details may require 2-4 weeks of generation time. Understanding these timelines empowers precise generation planning and stock management.

Regulatory compliance documentation must go with worldwide shipments counting certificates of investigation, well-being certificates, and country-specific permits. Experienced providers keep up administrative skill over different worldwide markets, disentangling compliance requirements for merchants. This mastery is especially important for companies entering unused geographic markets with new administrative frameworks.

Value-Added Services and Technical Support

Comprehensive specialized support includes detailing direction, application suggestions, and investigation help. Master specialized groups give important experiences for optimizing item execution and addressing detailing challenges. This back demonstrates particularly important during unused item improvement stages and scale-up operations.

Quality confirmation administrations incorporate incoming material assessment, batch testing, and a certificate of analysis. A few providers offer vendor-managed stock programs that consequently trigger reorders based on utilization designs. These administrations diminish authoritative burdens while guaranteeing reliable fabric availability.

Practical Considerations for Decision Making

Effective procurement decisions require aligning product specifications with specific end-use applications across pharmaceutical, nutraceutical, and food industry segments. Each application demands unique purity levels, functional properties, and regulatory compliance requirements. Understanding these distinctions enables precise supplier selection and optimal product specification development.

Application-Specific Requirements

Pharmaceutical applications request pharmaceutical-grade glucomannan assembly, exacting immaculateness and security requirements. These items require broad documentation, counting medicate ace records and administrative backup for item enrollment forms. Facility must keep up pharmaceutical-grade natural controls and approval protocols.

Nutraceutical applications adjust immaculateness requirements with fetched contemplations, while keeping up shopper security guidelines. Food-grade applications prioritize utilitarian execution and tangible nonpartisanship over greatest virtue levels. Understanding these application-specific needs guides detailed improvement and provider assessment criteria.

Long-Term Partnership Development

Successful provider connections expand past value-based acquiring toward vital organizations supporting shared development targets. Dependable providers illustrate steady quality, responsive communication, and proactive problem-solving capabilities. These connections give competitive preferences through special estimating, need allotment amid supply imperatives, and collaborative product development opportunities.

Regular provider reviews and execution audits keep up relationship quality while recognizing change opportunities. Key execution markers include on-time conveyance, quality consistency, and responsiveness to specialized requests. Setting up clear desires and communication conventions avoids errors while cultivating beneficial long-term partnerships.

Company Introduction and Product Service Information

Shaanxi Fairir Biotech stands as a recognized worldwide producer specializing in premium Pure Glucomannan Powder generation. Our 10,000 square meter GMP-certified facility consolidates advanced extraction gear, counting ceaseless countercurrent extraction frameworks, double-effect concentration hardware, and state-of-the-art shower drying innovation. This comprehensive framework empowers steady generation of high-quality glucomannan powder assembly determinations from 85-95% immaculateness levels.

Our quality control research facility highlights High-Performance Fluid Chromatography, UV spectrophotometers, and revolving vanishing gear, guaranteeing thorough testing conventions. Fourteen stainless steel extraction tanks extending from 500 to 3000 liters capacity, bolster adaptable clump measuring for assorted client prerequisites. Two completely computerized generation lines accomplish extraction productivity up to 98%, illustrating our commitment to operational excellence.

Comprehensive Product Portfolio

Our Pure Glucomannan Powder portfolio includes numerous grades custom-made for pharmaceutical, nutraceutical, and nourishment applications. Standard details extend from 85% to 95% immaculateness with CAS number 37200-17-2 confirmation. Item designs incorporate bulk powder, pre-encapsulated alternatives, and custom definitions supporting assorted fabricating requirements.

Quality certifications incorporate natural certification, gluten-free confirmation, and comprehensive allergen testing. Our items keep up a non-GMO status while guaranteeing paraben-free, color-free, and BSE/TSE-free compliance. These certifications bolster administrative endorsements over worldwide markets, while advancing buyer inclinations for clean-label ingredients.

Manufacturing Excellence and Service Commitment

Advanced extraction methodologies ensure superior product quality through careful selection of premium konjac roots and precise purification processes. Stringent quality control procedures encompass raw material inspection through finished product verification. Every production batch undergoes comprehensive testing, including HPLC analysis, UV spectrophotometry, and microbiological screening.

Our global logistics network supports efficient delivery with standard lead times of 1-3 working days for stock items. Packaging options include vacuum aluminum foil bags and 25kg fiber drums with food-grade poly bag liners. Custom packaging solutions accommodate specific customer requirements while maintaining product integrity throughout transportation and storage.

Conclusion

Selecting optimal Pure Glucomannan Powder requires systematic evaluation of purity specifications, supplier capabilities, and application requirements. Quality products demonstrate 85-95% purity levels, originate from GMP-certified facilities, and undergo rigorous analytical testing via HPLC and UV spectrophotometry. Successful procurement strategies emphasize long-term supplier partnerships, comprehensive quality documentation, and responsive technical support. Global buyers benefit from understanding application-specific requirements, regulatory compliance needs, and value-added services that enhance procurement efficiency. The growing demand for natural, functional ingredients positions glucomannan as a strategic raw material for innovative product development across pharmaceutical, nutraceutical, and food industry segments.

FAQ

What specifications should I look for in Pure Glucomannan Powder?

Quality Pure Glucomannan Powder should meet 85-95% purity specifications with proper analytical verification through HPLC and UV testing methods. The product should exhibit an off-white to white powder appearance with consistent particle size distribution. Essential documentation includes Certificates of Analysis confirming molecular weight profile, moisture content below 10%, and comprehensive microbiological safety testing. GMP-certified manufacturing origin ensures regulatory compliance across international markets.

How does glucomannan powder differ from konjac flour?

Glucomannan powder represents a highly purified extract containing 85-95% glucomannan content, while konjac flour typically contains 40-60% glucomannan along with other plant components. The purification process removes starches, proteins, and fiber components present in raw konjac flour. This higher purity level provides superior functional performance, including enhanced water absorption capacity and improved gel-forming properties essential for pharmaceutical and nutraceutical applications.

What are the recommended dosage ranges for different applications?

Weight management formulations typically utilize 1-3 grams daily dosages taken before meals with adequate water intake. Blood sugar control applications often employ 0.5-1 gram dosages integrated into meal planning. Food applications require precise dosing based on desired viscosity and texture modification goals. Professional formulation guidance ensures optimal dosing while maintaining safety and efficacy standards across diverse application requirements.

Which packaging options best preserve product quality?

Vacuum aluminum foil bags provide optimal moisture protection for smaller quantities while maintaining product stability during storage and transportation. Industrial-scale shipments benefit from 25kg fiber drums with double-layer food-grade poly bag liners offering enhanced protection against environmental contamination. Temperature-controlled storage below 25°C with relative humidity control extends shelf life while preserving functional properties. Proper packaging prevents moisture absorption that could compromise product performance.

Partner with Fairir for Premium Pure Glucomannan Powder Supply

Shaanxi Fairir Biotech offers comprehensive solutions for global procurement teams seeking reliable Pure Glucomannan Powder manufacturer partnerships. Our GMP-certified facility delivers consistent quality backed by advanced analytical testing and responsive technical support. Experience competitive pricing through direct manufacturer relationships while accessing custom formulation services and private label manufacturing capabilities. Contact our sales team at sales@fairirbiotech.com to request samples, bulk quotations, and detailed product specifications tailored to your specific requirements.

References

1. Chen, H.L., Sheu, W.H., Tai, T.S., Liaw, Y.P., Chen, Y.C. (2003). Konjac supplement alleviated hypercholesterolemia and hyperglycemia in type 2 diabetic subjects. Journal of the American College of Nutrition, 22(1), 36-42.

2. Keithley, J., Swanson, B. (2005). Glucomannan and obesity: a critical review. Alternative Therapies in Health and Medicine, 11(6), 30-34.

3. Sood, N., Baker, W.L., Coleman, C.I. (2008). Effect of glucomannan on plasma lipid and glucose concentrations, body weight, and blood pressure: systematic review and meta-analysis. The American Journal of Clinical Nutrition, 88(4), 1167-1175.

4. Walsh, D.E., Yaghoubian, V., Behforooz, A. (1984). Effect of glucomannan on obese patients: a clinical study. International Journal of Obesity, 8(4), 289-293.

5. Wood, R.J., Fernandez, M.L., Sharman, M.J., Silvestre, R., Greene, C.M., Zern, T.L., Shrestha, S., Judelson, D.A., Gomez, A.L., Kraemer, W.J., Volek, J.S. (2007). Effects of a carbohydrate-restricted diet with and without supplemental soluble fiber on plasma low-density lipoprotein cholesterol and other clinical markers of cardiovascular risk. Metabolism, 56(1), 58-67.

6. Yoshida, M., Vanstone, C.A., Parsons, W.D., Zawistowski, J., Jones, P.J. (2006). Effect of plant sterols and glucomannan on lipids in individuals with and without type II diabetes. European Journal of Clinical Nutrition, 60(4), 529-537.

_1751965378790.webp)