When sourcing Ganoderma Lucidum Extricate Powder for bulk supply, producers must explore complex quality parameters that straightforwardly affect product quality and advertise acknowledgment. This concentrated frame of reishi mushroom, accessible in standardized 10:1 and 20:1 proportions, speaks to a basic ingredient for pharmaceutical, nutraceutical, and restorative applications. Understanding the fabrication considerations guarantees acquisition groups secure high-quality extricates that meet rigid industry necessities, while keeping up competitive estimating structures. This comprehensive document looks at fundamental fabricating contemplations counting crude fabric sourcing guidelines, advanced extraction methods, quality control measures, packaging arrangements, and provider assessment criteria. Each thought specifically impacts the last product's bioactivity, rack stability, and administrative compliance over worldwide markets.

Understanding Ganoderma Lucidum Extract Powder: Quality and Composition

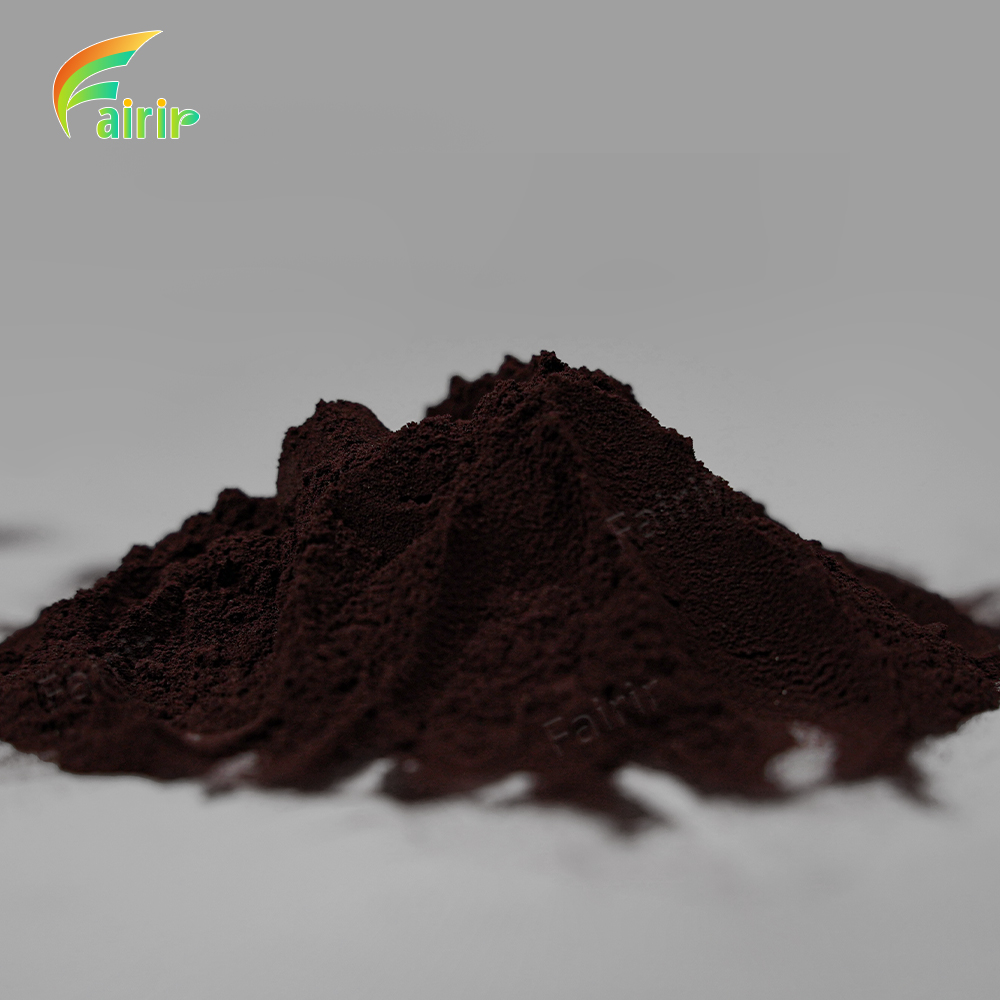

Ganoderma Lucidum extract powder is a high-value ingredient that is different from raw mushroom powders because it is concentrated and pure. It is known for its antioxidant, immune-supportive, anti-inflammatory, and possibly cancer-preventive qualities. The characteristic brown powder look shows that the extraction and processing steps were done correctly, and the standard concentration ratios make sure that the bioactive substance is delivered consistently across all production batches.

Extract Purity and Concentration Standards

Premium reishi extract powder stays at certain concentration levels. It is usually sold in 10:1 and 20:1 ratios, which means that 10 or 20 kg of raw mushroom material makes 1 kg of concentrated extract. These ratios are directly related to the amounts of polysaccharides and triterpenes, which are the main bioactive compounds that have therapeutic benefits. Manufacturers who use advanced extraction methods get higher amounts of purity while keeping heat-sensitive compounds that help change the immune system.

Organic Certification and Quality Parameters

Natural, gluten-free, non-GMO, and allergen-free determinations have become standard necessities for B2B clients serving health-conscious buyer markets. These certifications require comprehensive documentation throughout the supply chain, from crude fabric development to last bundling. BSE/TSE-free and vegetarian compliance advance extend showcase openness, especially for pharmaceutical applications requiring strict defilement controls.

B2B buyers must center on quality parameters, counting extricate immaculateness, concentration levels, and the quality between natural and routine sources. Keeping up reliable quality in unadulterated extricates versus mixed details remains pivotal, whereas overcoming defilement and contaminated dangers in bulk fabricating requires modern quality control frameworks.

Raw Material Sourcing and Supplier Selection

Getting genuine Ganoderma Lucidum Extricate Powder is the first step in making high-quality extract powder. The growing conditions, when the harvest is done, and the processing that happens afterward all have a big impact on the bioactive compound profile and therapeutic potential of the finished extract.

Certified Organic Cultivation Requirements

To make sure the integrity of the raw materials, procurement managers should give priority to approved organic growers with full traceability systems. Organic farming gets rid of chemical residues and heavy metal contamination. It also uses sustainable farming methods that keep supplies stable over time. Traceability paperwork should have records of when the plants were grown, when they were harvested, how they were stored, and how they were moved. These records should show the chain of custody throughout the supply chain.

Supplier Evaluation Criteria

Provider assessment must amplify past estimating contemplations to incorporate notoriety evaluation, bulk supply capacity, private name capabilities, and adherence to GMP and ISO certifications. Fabricating facilities ought to illustrate reliable production volumes capable of assembling large-scale B2B necessities while maintaining batch-to-batch consistency. Free test accessibility permits acquisition groups to conduct preparatory testing, sometimes recently committing to bulk orders, lessening acquisition dangers related to unused provider relationships.

Supply chain unwavering quality and shipping coordination minimize operational disturbances that may affect generation plans. Providers advertising 1-3 working day conveyance times give competitive points of interest for just-in-time stock administration procedures. Viably moderating these challenges underpins feasible sourcing procedures conducive to reliable group quality and competitive showcase positioning.

Manufacturing Processes and Extraction Techniques

To make good reishi extract powder, you need to find the best extraction methods that keep the beneficial compounds while still getting the most out of the plant. Modern extraction technologies have changed the business by making it possible to get higher purity levels while still keeping production scales low.

Advanced Extraction Methodologies

Traditional ways of extracting bioactive compounds are often inefficient and increase the risk of impurities. Newer technologies, like hot water extraction, alcohol extraction, and supercritical CO₂ extraction, are better at recovering these compounds. For pharmaceutical-grade uses, supercritical CO₂ extraction is the gold standard. It uses solvent-free processing to keep heat-sensitive compounds safe while getting rid of any leftover solvent contamination.

Up to 98% of the time, state-of-the-art facilities with continuous countercurrent extraction tools, double-effect concentration systems, and vacuum belt drying technology can get the job done. These automated production lines make sure that the factors of the processing are always the same and reduce the risks of contamination and human error.

Quality Control and Testing Protocols

Basic fabricating parameters counting temperature control, dissolution determination, extraction term, concentration levels, and drying conditions, specifically impact item consistency. HPLC, UV spectrophotometry, and GC testing strategies givea comprehensive examination of bioactive compound profiles, guaranteeing each bunch meets predefined specifications.

Standardizing these forms for large-scale generation through strict quality affirmation conventions guarantees batch-to-batch consistency vital for worldwide B2B supply contracts. In-house research facility testing combined with third-party confirmation gives comprehensive documentation supporting administrative compliance across different locales.

Packaging, Storage, and Regulatory Compliance

Bulk reishi extract powder needs to be packaged in a way that keeps it from getting contaminated and maintains its bioactivity during foreign shipping and long storage periods. Professional packaging methods have a direct effect on how long a product lasts and how well it does in the market.

Protective Packaging Systems

Bioactive substances can be damaged by moisture, oxygen, and light, but vacuum aluminum foil bags protect them from these things. Extra protection during shipping and storage is provided by secondary packing in fiber drums with double-layer food-grade poly bag inserts. These multi-layer methods keep the integrity of the product for a long time while making it easy to handle in business settings.

Storage and Stability Considerations

Proper storing conditions, such as controlling the temperature and humidity, keep products stable throughout the distribution chain and extend their shelf life. Climate-controlled storage keeps products from absorbing water and breaking down due to heat, which could lower their quality before they reach customers.

Global food safety standards and export rules say that you have to keep very detailed records, make sure your labels are correct, and keep your certifications up to date. These standards are in line with what B2B customers want and make it easier for goods to get through customs and be accepted by markets around the world. Full certificate of analysis paperwork backs up claims of quality and regulatory submissions in all foreign markets.

Strategic Advantages of Selecting a Trusted Ganoderma Lucidum Extract Powder Supplier

Working with an experienced manufacturer has real benefits that go beyond just getting products. These benefits include full business help and the ability to come up with new ideas. These benefits are shown by Shaanxi Fairir Biotech Co., Ltd., which uses modern manufacturing techniques and provides service with the customer in mind.

Manufacturing Excellence and Innovation

Our GMP-certified facility is 10,000 square meters and has high-tech extraction tools, such as 14 stainless steel tanks with capacities ranging from 500 to 3,000 liters. Two fully automatic production lines are very efficient and keep high-quality standards throughout the whole process of making the products. For time-sensitive B2B needs, this infrastructure allows flexible production scheduling and quick order fulfillment.

Customization and Private Label Services

There are many ways to customize products, such as capsules, tablets, softgels, gummies, and small bag packing that can be made to fit the needs of each market. Private label manufacturing services offer full branding solutions and flexible minimum order quantities so that businesses of all kinds can use them. Custom recipe development helps differentiate products in specific ways while staying in line with regulations in all target markets.

Trusted suppliers offer OEM partnerships that include certification help and custom packing solutions that make the supply chain work better and help businesses grow. Pricing structures that are clear and based on volume, along with flexible logistics options, give B2B clients trust while making procurement easier.

Conclusion

To successfully buy Ganoderma Lucidum Extract Powder in bulk, you need to carefully consider production factors that affect the quality of the product, compliance with regulations, and acceptance by the market. The therapeutic effectiveness and commercial viability of the finished product depend on things like the authenticity of the raw materials, advanced extraction methods, strict quality control, and professional packaging systems. When you work with well-known makers that have GMP certification, advanced testing tools, and a lot of customization options, you can be sure that your supply chain will work well and help your business grow over the long term in the competitive health and wellness markets.

FAQ

Q1: What is the typical dosage recommendation for Ganoderma Lucidum extract powder in bulk orders?

A: Dosage recommendations vary significantly based on extract concentration ratios and intended applications. Our 10:1 and 20:1 standardized extracts allow manufacturers to customize dosing protocols aligned with specific formulation requirements, ensuring precise bioactive compound delivery for pharmaceutical, nutraceutical, and functional food applications.

Q2: How does Ganoderma Lucidum extract powder compare to capsules in terms of efficacy and cost efficiency?

A: Bulk extract powder offers superior formulation flexibility and cost efficiency at commercial scales, enabling manufacturers to develop customized products while maintaining competitive pricing structures. Capsules provide consumer convenience but typically carry higher per-dose costs due to additional processing and packaging requirements.

Q3: Are there specific storage requirements for maintaining Ganoderma Lucidum extract powder quality during extended warehousing?

A: Proper storage requires controlled temperature and humidity conditions to prevent moisture absorption and bioactive compound degradation. Our vacuum aluminum foil packaging with fiber drum protection maintains product stability for extended periods when stored in climate-controlled environments away from direct sunlight and extreme temperature fluctuations.

Partner with Fairir for Premium Ganoderma Lucidum Extract Powder Supply

Ready to secure a reliable supply of premium reishi extract powder for your manufacturing operations? Shaanxi Fairir Biotech Co., Ltd. offers comprehensive solutions, including organic certification, custom formulation development, and flexible packaging options tailored to your specific requirements. Our advanced extraction capabilities and GMP-certified facility ensure consistent quality, while competitive pricing supports your market positioning objectives. As a trusted Ganoderma Lucidum Extract Powder manufacturer, we provide complete documentation, rapid delivery, and technical support throughout our partnership. Contact us at sales@fairirbiotech.com to discuss your bulk supply needs and request complimentary samples for evaluation.

References

1. Chen, S., Xu, J., Liu, C., Zhu, Y., Nelson, D. R., Zhou, S., ... & Xu, Z. (2012). Genome sequence of the model medicinal mushroom Ganoderma lucidum. Nature communications, 3(1), 913.

2. Bishop, K. S., Kao, C. H., Xu, Y., Glucina, M. P., Paterson, R. R., & Ferguson, L. R. (2015). From 2000 years of Ganoderma lucidum to recent developments in nutraceuticals. Phytochemistry, 114, 56-65.

3. Wachtel-Galor, S., Yuen, J., Buswell, J. A., & Benzie, I. F. (2011). Ganoderma lucidum (Lingzhi or Reishi): A medicinal mushroom. In Herbal Medicine: Biomolecular and Clinical Aspects. 2nd edition. CRC Press.

4. Paterson, R. R. (2006). Ganoderma–a therapeutic fungal biofactory. Phytochemistry, 67(18), 1985-2001.

5. Ahmad, M. F. (2018). Ganoderma lucidum: Persuasive biologically active constituents and their health endorsement. Biomedicine & Pharmacotherapy, 107, 507-519.

6. Jin, X., Ruiz Beguerie, J., Sze, D. M. Y., & Chan, G. C. (2012). Ganoderma lucidum (Reishi mushroom) for cancer treatment. Cochrane Database of Systematic Reviews, (6).

_1751965378790.webp)