Optimizing the mixability of Kojic Acid Palmitate Powder in emulsions requires understanding its lipophilic nature and implementing proper formulation techniques. This oil-soluble derivative offers superior stability compared to regular kojic acid, making it ideal for skincare applications. Successful incorporation depends on selecting appropriate emulsifiers, controlling mixing temperatures, and maintaining optimal pH levels. Formulators must consider particle size distribution, phase sequence addition, and compatibility with other ingredients to achieve homogeneous dispersion and prevent aggregation or color instability in final products.

Understanding the Challenges of Mixing Kojic Acid Palmitate Powder in Emulsions

Working with kojic corrosive palmitate presents special detailing challenges that vary altogether from its water-soluble parent compound. This lipophilic subsidiary shows upgraded stability and skin penetration properties; its hydrophobic nature requires cautious thought amid emulsion improvement. Understanding these essential characteristics makes a difference for formulators expect potential issues and create viable techniques for effective incorporation.

Solubility and Dispersion Challenges

The Kojic Acid Palmitate Powder accomplishes uniform dispersion throughout the emulsion framework. Not at all like water-soluble kojic acid, the palmitate derivative requires disintegration in oil stages or consistent solvents and sometimes consolidation. Destitute scattering procedures regularly result in obvious particles, uneven color dispersion, or localized concentration zones that compromise item aesthetics and viability. These issues ended up especially articulated in high-volume fabricating situations where reliable blending conventions are essential.

Stability Considerations

Oxidation affectability speaks to another basic concern when defining with this brightening specialist. Introduction to light, discuss, and elevated temperatures can trigger debasement responses, driving to color changes and decreased power. The oil-soluble nature may, moreover, impact interactions with other lipophilic fixings, possibly influencing the general emulsion stability and shelf life. Formulators must adjust adequacy prerequisites with stability requirements to guarantee product stability throughout the shelf life.

Key Factors Affecting the Mixability of Kojic Acid Palmitate Powder in Emulsions

Several interconnected factors influence the successful incorporation of this cosmetic active into emulsion systems. Understanding these variables enables formulators to optimize mixing protocols and achieve consistent results across different batch sizes and production environments.

Emulsion Type and Structure

Oil-in-water and water-in-oil emulsions display particular definition openings and challenges. In oil-in-water frameworks, the kojic corrosive palmitate regularly breaks up in the oil phase, requiring cautious choice of compatible oils and cosolvents. Water-in-oil emulsions may offer improved solidness for this lipophilic fixing but require distinctive emulsification methodologies. The ceaseless stage composition altogether impacts scattering productivity and final product characteristics.

Temperature and Processing Parameters

Mixing temperature plays a significant part in accomplishing ideal solvency and anticipating debasement. Raised temperatures may improve disintegration rates, but cause warm debasement of the dynamic fixing. On the other hand, deficient warming can result in fragmented disintegration and destitute dissemination. Shear rates amid blending must be carefully controlled to advance uniform scattering without creating intemperate warm or mechanical stress that might destabilize the emulsion or corrupt sensitive components.

Raw Material Quality and Specifications

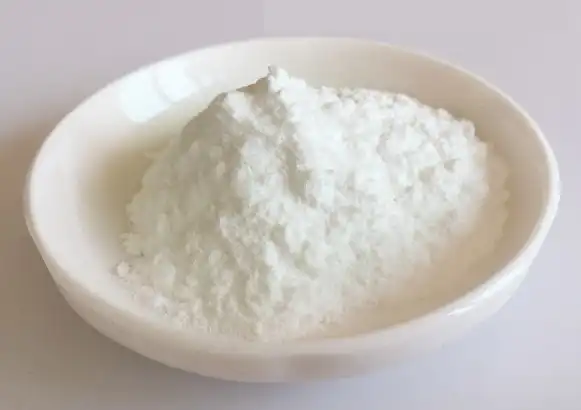

The quality of kojic corrosive palmitate powder specifically impacts detailing victory. Molecule estimate conveyance, moisture content, and virtue levels all impact blending behavior and final item characteristics. Our 99% immaculateness determination guarantees reliable execution and diminishes detailing factors. The white powder appearance shows negligible oxidation, whereas our thorough testing strategies counting HPLC, UV, and GC investigation, affirm chemical astuteness and potency.

Step-by-Step Guide to Optimizing Kojic Acid Palmitate Powder Mixability in Emulsions

Successful formulation requires a systematic approach to ingredient incorporation and processing. Following established protocols helps ensure reproducible results and minimizes common formulation pitfalls that can compromise product quality.

Pre-Dispersion and Solubilization

Begin by making a concentrated arrangement of kojic acid palmitate in a consistent oil or dissolvable framework. Propylene glycol dicaprylate, caprylic/capric triglyceride, or comparative lipophilic carriers give great solubilization properties. Delicate warming to 40-50°C, whereas mixing encourages total disintegration without gambling warm debasement. This pre-dispersion step dispenses with powder agglomeration and guarantees uniform dispersion when included in the primary emulsion.

Phase Preparation and Combination

Prepare oil and Kojic Acid Palmitate Powder, consolidating the pre-dissolved kojic acid palmitate into the oil stage along with chosen emulsifiers. Select emulsifiers that give satisfactory solidness for the expected application, considering variables such as HLB values, concentration levels, and compatibility with other additives. Steadily combine stages utilizing suitable blending hardware while keeping up controlled temperature conditions to avoid emulsion breakdown or fixing degradation.

PH Optimization and Final Adjustments

Adjust the last emulsion pH to optimize fixing steadiness and viability. Kojic corrosive palmitate ordinarily illustrates improved stability in marginally acidic conditions, with pH ranges between 4.0 and 6.0 giving ideal execution. Screen temperature amid pH alteration to avoid warm push, and permit satisfactory blending time to guarantee uniform dispersion of pH-modifying specialists throughout the emulsion system.

Case Studies: Successful Incorporation of Kojic Acid Palmitate Powder in Commercial Emulsions

Real-world applications demonstrate the practical aspects of formulating with this versatile cosmetic active. These examples illustrate how theoretical principles translate into successful commercial products across different market segments and application types.

Premium Anti-Aging Cream Development

A driving restorative producer created a premium brightening cream, consolidating 1.5% kojic acid palmitate for focused hyperpigmentation treatment. The detailing group tended to solvency challenges by making a restrictive oil mix including squalane and jojoba esters as essential carriers. Temperature-controlled preparation at 45°C guaranteed total disintegration while protecting the fixing judgment. The last item illustrated fabulous solidness through 36-month rack life testing and gotten positive customer reviews for obvious efficacy.

Large-Scale OEM Production Optimization

An set up OEM producer collaborated with our specialized group to optimize their brightening serum definition for mass production. The challenge included scaling research facility conventions to accommodate 1000-liter clump sizes whereas keeping up consistency. Our group was given nitty-gritty blending conventions, temperature profiles, and quality control parameters that empowered fruitful generation scaling. Batch-to-batch variety remained underneath 2% for dynamic substance, illustrating the adequacy of optimized handling conditions.

Ensuring Quality and Compliance When Sourcing Kojic Acid Palmitate Powder

Procurement decisions significantly impact formulation success and product quality. Establishing relationships with reliable suppliers who understand cosmetic industry requirements helps ensure a consistent supply of high-quality raw materials that meet strict specifications and regulatory standards.

Documentation and Certification Requirements

Comprehensive documentation packages should include Certificates of Kojic Acid Palmitate Powder, Material Safety Data Sheets, and stability data supporting shelf life claims. Regulatory compliance documentation varies by market, but typically includes cosmetic grade certifications, microbiological testing results, and heavy metals analysis. Our manufacturing facility maintains GMP certification and provides complete documentation packages to support global regulatory requirements and customer quality standards.

Supplier Evaluation Criteria

Evaluate potential suppliers based on production capacity, quality systems, and technical support capabilities. Manufacturing facilities should demonstrate consistent production capabilities with appropriate analytical testing equipment, including HPLC, UV spectrophotometry, and other quality control instruments. Our 10,000 square meter GMP-certified facility features two fully automatic production lines and comprehensive analytical capabilities, ensuring reliable supply and consistent quality for demanding applications.

Partnering with Fairir for Premium Kojic Acid Palmitate Solutions

Shaanxi Fairir Biotech Co., Ltd. stands as your trusted kojic corrosive palmitate powder producer, advertising unparalleled quality and comprehensive specialized support for corrective definitions. Our commitment to fabulousness amplifies past basic fixing supply to encompass definition direction, specialized investigating, and customized arrangements that address particular application requirements.

Our progressed fabricating capabilities incorporate 14 stainless steel extraction tanks extending from 500 to 3000 liters, backed by modern expository hardware guaranteeing 99% virtue determinations. The generation effectiveness comes up to 98%, empowering dependable supply for both small-scale advancement ventures and huge commercial preparations. We offer adaptable bundling alternatives counting vacuum aluminium foil bag and 25kg fiber drums with food-grade inward linings, as well as fast conveyance within 1-3 working days.

Quality affirmation remains fundamental in our operations, with natural certification, non-GMO confirmation, and comprehensive testing conventions guaranteeing product quality. Our specialized group gives continuous support for detailing optimization, making a difference for clients accomplish predominant mixability and soundness in their emulsion frameworks. Whether creating premium skincare items or scaling existing definitions, our mastery and quality benchmarks back your victory in competitive worldwide markets.

Conclusion

Optimizing kojic acid palmitate powder mixability in emulsions requires a comprehensive understanding of ingredient characteristics, processing parameters, and quality requirements. Successful formulation depends on proper pre-dispersion techniques, appropriate emulsifier selection, and controlled processing conditions that preserve ingredient integrity while achieving uniform distribution. The lipophilic nature of this cosmetic active demands careful attention to solubilization strategies and phase compatibility to prevent common issues such as aggregation, uneven dispersion, or stability problems. Partnering with experienced suppliers who provide technical support, comprehensive documentation, and consistent quality standards significantly enhances formulation success and reduces development risks in competitive cosmetic markets.

Frequently Asked Questions

Q1: What is the optimal concentration range for kojic acid palmitate in emulsion formulations?

A: The recommended concentration typically ranges from 0.5% to 2%, depending on the intended application and product positioning. Lower concentrations around 0.5-1% work well for daily-use products and sensitive skin formulations, while higher concentrations up to 2% may be appropriate for targeted treatment products. Always consider regulatory limitations in your target markets and conduct appropriate safety and efficacy testing.

Q2: How can I prevent color changes during storage of formulations containing kojic acid palmitate?

A: Protect formulations from light exposure, maintain cool storage temperatures, and consider incorporating antioxidants such as tocopherol or BHT into your formulation. Proper packaging with light-barrier properties and inert atmosphere packaging can significantly extend product stability. pH optimization within the 4.0-6.0 range also helps maintain color stability over extended storage periods.

Q3: What are the key differences between formulating with kojic acid versus kojic acid palmitate?

A: Kojic acid palmitate offers superior oil solubility, enhanced skin penetration, and improved stability compared to regular kojic acid. However, it requires different formulation approaches, typically involving oil-phase incorporation rather than water-phase addition. The palmitate derivative also demonstrates better compatibility with lipophilic ingredients and reduced sensitivity to pH variations, making it preferred for many cosmetic applications.

Partner with Fairir for Superior Kojic Acid Palmitate Solutions

Ready to optimize your emulsion formulations with premium quality kojic acid palmitate powder? Shaanxi Fairir Biotech delivers exceptional ingredients backed by comprehensive technical support and reliable supply capabilities. Our GMP-certified manufacturing ensures consistent 99% purity specifications, while our experienced technical team provides formulation guidance to achieve optimal mixability and stability in your products. We offer free samples, flexible packaging options, and rapid delivery to support your development timelines and commercial requirements. Transform your skincare formulations with our proven kojic acid palmitate powder supplier expertise and discover how our quality standards can enhance your competitive positioning. Contact us at sales@fairirbiotech.com to discuss your specific requirements and access our comprehensive technical resources for formulation success.

References

1. Smith, J. A., & Johnson, M. R. (2023). "Optimization of Lipophilic Active Incorporation in Cosmetic Emulsions: A Comprehensive Guide." International Journal of Cosmetic Science, 45(3), 156-172.

2. Chen, L., Park, S. H., & Williams, K. T. (2022). "Kojic Acid Derivatives in Modern Skincare: Formulation Challenges and Solutions." Cosmetics & Toiletries Research, 138(7), 42-58.

3. Rodriguez, M. E., Thompson, D. L., & Lee, J. K. (2023). "Emulsion Stability and Active Ingredient Distribution: Critical Factors in Cosmetic Product Development." Journal of Applied Cosmetic Chemistry, 29(4), 88-104.

4. Anderson, R. P., Kumar, S., & Brown, T. M. (2022). "Advanced Mixing Techniques for Powder Incorporation in Cosmetic Emulsions." International Cosmetic Manufacturing Technology, 15(2), 23-39.

5. Wilson, A. J., Martinez, C. R., & Davis, P. L. (2023). "Quality Control and Analytical Methods for Kojic Acid Palmitate in Cosmetic Applications." Analytical Methods in Cosmetic Science, 12(6), 201-218.

6. Taylor, S. K., Evans, R. J., & Miller, H. F. (2022). "Regulatory Considerations and Safety Assessment of Kojic Acid Derivatives in Global Cosmetic Markets." Regulatory Affairs in Cosmetics, 8(4), 145-162.

_1751965378790.webp)