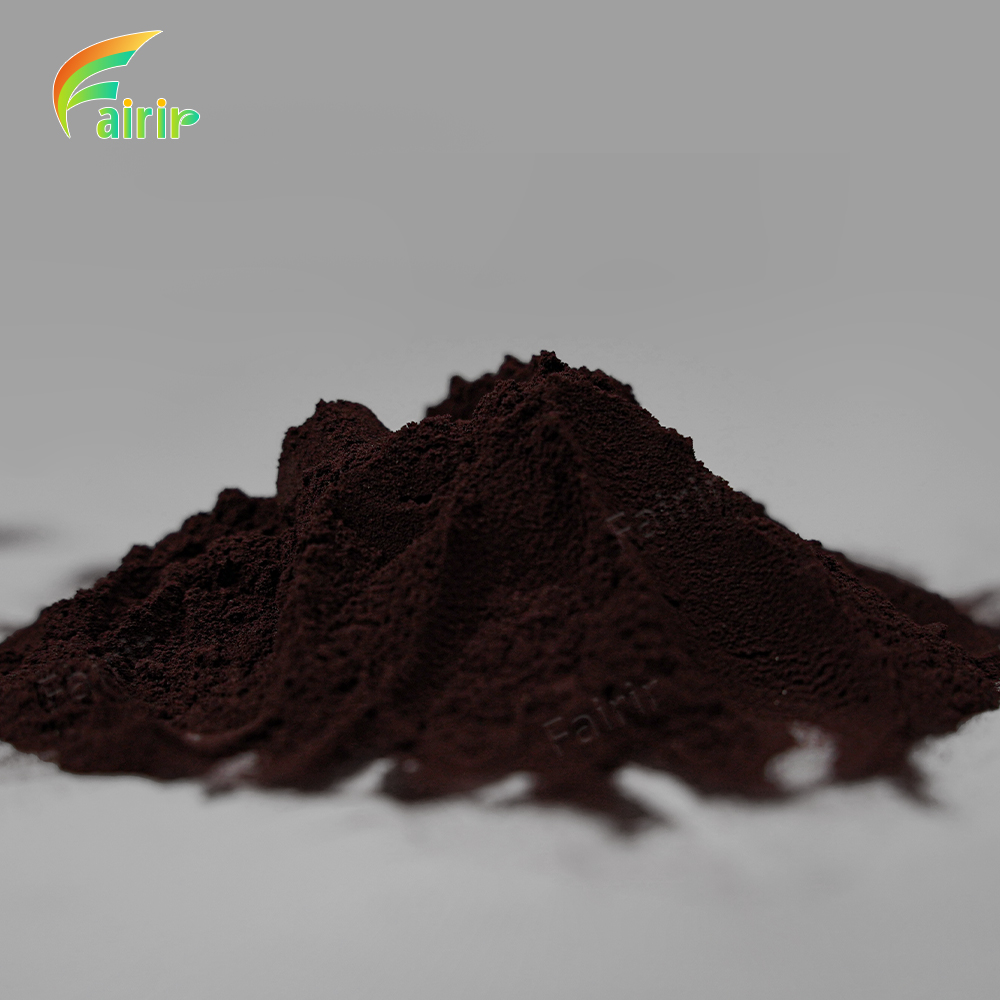

Natural Lutein Powder: Sourcing And Extraction Methods

Common lutein powder has ended up a enormous bargain in the wellbeing and wellness world since it is a effective antioxidant that may moreover be great for your wellbeing. A part of distinctive things utilize this shinning yellow to orange powder, which is generally made from marigold blossoms. It's utilized in drugs, supplements, excellence items, and solid nourishments. Finding and evacuating characteristic lutein powder such as Natural Lutein Powder is a complicated handle that incorporates progressed extraction innovations, strict quality control measures, and cultivating strategies. It goes into extraordinary profundity almost how to make common lutein powder in this piece. It talks approximately the diverse places makers get their fixings from and the most current ways to get them out of plants that make beyond any doubt the last item is the best and most grounded conceivable. If we know these steps, we can learn a part around how characteristic lutein gets from the field to the powder. We will be able to way better get it the science and ability behind this effective nourishment fixing.

What are the primary sources of natural lutein powder?

Marigold Flowers: The Golden Standard

Marigold flowers (Tagetes erecta) stand as the primary and most widely used source for natural lutein powder extraction. There are a lot of lutein esters in these bright blooms, which can be easily turned into free lutein during the extraction process. To get the most lutein out of marigolds grown just for that purpose, careful farming methods must be used. The final lutein amount depends on many things, including the quality of the soil, the weather, and the way the plants are harvested. Natural lutein powder manufacturers often work closely with farmers to ensure optimal growing conditions and implement sustainable farming practices. The flowers are typically harvested at peak maturity when lutein concentrations are at their highest, then carefully dried to preserve their nutritional integrity before undergoing extraction.

Green Leafy Vegetables: A Complementary Source

While marigolds remain the primary source, some natural lutein powder producers also explore alternative sources to diversify their product offerings. A lot of lutein can be found in green leafy veggies like spinach, kale, and collard greens. Compared to marigolds, these vegetables have a different lutein profile and often have higher amounts of zeaxanthin, which is another good carotenoid. Getting lutein out of these sources can be harder because they have less of it and other plant chemicals are present. But as extraction methods have improved, it has become easier to make natural lutein powder from these vegetable sources. This variety lets companies make their own special lutein blends and meet the needs of people who want plant-based options.

Emerging Sources: Microalgae and Bioengineered Options

Researchers have looked into new ways to get natural lutein powder because they want to find sources that are safe and effective. Some microalgae, like Chlorella and Dunaliella, have shown promise as possible sources of lutein. These tiny living things can be grown in controlled settings, which could lead to a more sustainable and scalable way to make natural lutein powder. Also, bioengineering methods are being developed to make lutein production better in common plant sources or even to make new creatures that can produce large amounts of lutein. While these emerging sources are still in the research and development phase, they represent exciting possibilities for the future of natural lutein powder production, potentially revolutionizing sourcing methods and expanding the availability of this valuable nutrient.

How is natural lutein powder extracted from its sources?

Solvent Extraction: The Traditional Approach

Solvent extraction remains one of the most widely used methods for obtaining natural lutein powder from plant sources. This process typically involves using organic solvents such as hexane or ethanol to dissolve and extract the lutein from the plant material. The dried and ground source material is mixed with the solvent, allowing the lutein to be dissolved and separated from other plant components. After extraction, the solvent is carefully removed through evaporation, leaving behind a concentrated lutein oleoresin. This oleoresin then undergoes further processing, including saponification to convert lutein esters into free lutein, and purification steps to remove any residual impurities. The resulting natural lutein powder is then standardized to achieve the desired concentration, usually ranging from 5% to 80% lutein content. While effective, solvent extraction methods require strict controls to ensure the complete removal of solvents and maintain the purity of the final natural lutein powder product.

Supercritical Fluid Extraction: A Green Alternative

As the demand for cleaner and more environmentally friendly extraction methods grows, supercritical fluid extraction (SFE) has gained popularity in the production of natural lutein powder. This technique typically uses carbon dioxide (CO2) in its supercritical state as the extraction medium. Under specific temperature and pressure conditions, supercritical CO2 exhibits properties of both a liquid and a gas, allowing it to efficiently penetrate plant material and dissolve lutein and other desired compounds. One of the main advantages of SFE is that it leaves no solvent residues, as the CO2 simply evaporates once the pressure is released, resulting in a pure natural lutein powder. This method is particularly well-suited for heat-sensitive compounds like lutein, as it operates at relatively low temperatures, helping to preserve the integrity of the extract. While SFE requires specialized equipment and expertise, it offers a "green" extraction option that aligns with the growing consumer demand for clean-label and environmentally conscious products.

Ultrasound-Assisted Extraction: Enhancing Efficiency

Ultrasound-assisted extraction (UAE) is a new method that has the potential to make the production of natural lutein powder more efficient and increase the yield. High-frequency sound waves are used in this method to make cavitation bubbles in the extraction medium. These bubbles break and create micro-jets that damage plant cell walls, which makes it easier for lutein and other compounds that are wanted to be released. UAE can be used with traditional solvent extraction or as part of a water-based extraction method that is better for the environment. UAE has shown that when used to remove natural lutein powder, it can shorten the extraction time, use less solvent, and maybe even get higher lutein yields than traditional methods. The gentle climate of the UAE also helps keep the extracted lutein stable, which guarantees a high-quality end product. As companies keep looking for better ways to extract materials, UAE is a useful tool for making natural lutein powder because it strikes a good mix between efficiency and product quality.

What are the key quality control measures in natural lutein powder production?

Raw Material Sourcing and Testing

The journey to producing high-quality natural lutein powder begins with stringent raw material sourcing and testing protocols. Manufacturers must carefully select and qualify suppliers who can consistently provide marigold flowers or other source materials with optimal lutein content. When these raw materials are received, they are carefully tested to make sure they have the right amount of lutein, check their general quality, and look for any possible contaminants. To correctly measure lutein levels, high-performance liquid chromatography (HPLC) and other advanced analytical methods are used. To make sure the starting material is safe and pure, it is also tested for heavy metals, herbicide residues, and microbial contamination. Producers of natural lutein powder can build a strong foundation for the quality of their end product by strictly controlling the raw materials they use. This way, they can make sure that only the best ingredients get into the extraction process.

In-Process Controls and Monitoring

Several checks and balances must be done during the extraction and processing steps to make sure the quality of the natural lutein powder is maintained. To make sure the best lutein output and stability, these controls involve keeping a close eye on important factors like temperature, pressure, and extraction time. Regular sampling and testing during various stages of production allow manufacturers to make real-time adjustments to process conditions if necessary. For instance, during solvent extraction, the concentration of lutein in the extract is monitored to determine the optimal extraction time and prevent degradation. In supercritical fluid extraction, pressure and temperature are carefully controlled to maintain the supercritical state of CO2 and maximize extraction efficiency. These in-process controls not only help make sure that the quality of the product stays the same, but they also help to improve the process, which could help makers of natural lutein powder get higher yields and lower costs.

Final Product Testing and Certification

The final stage of quality control in natural lutein powder production involves comprehensive testing of the finished product to verify its composition, purity, and potency. Advanced analytical methods, such as HPLC and spectrophotometry, are used to prove the amount of lutein present and make sure it is at the right concentration. To make sure the powder is safe to eat, it is also tested for heavy metals, microbial contaminants, and liquids that are still present. To find out how long the natural lutein powder will last in different storage situations, stability tests are done. Many companies also look for third-party certifications, like USP (United States Pharmacopeia) verification or Non-GMO Project recognition, to give their customers even more peace of mind about the quality of their products. The strict tests and certificates for the wrapped up item offer assistance make beyond any doubt that the normal lutein powder meets all government measures and client needs. Because of this, it is a great fixing that can be utilized appropriately in numerous things, from makeup and utilitarian nourishments to dietary supplements.

Conclusion

Common lutein powder has gotten to be a important fixing in the wellbeing and wellness trade. It is made through a complicated prepare of sourcing and extricating lutein. It's imperative to take after all the steps to make beyond any doubt the item is of tall quality, from carefully developing marigold blooms to utilizing cutting-edge extraction innovations and strict quality control measures. As the require for normal lutein keeps developing, modern ways of finding sources and extricating it are likely to show up. These might make the handle more productive, final longer, and deliver way better comes about. Both producers and shoppers can advantage from knowing these steps. This will offer assistance them make keen choices and appreciate the science behind this effective antioxidant.

Shaanxi Fairir Biotech Co., Ltd. is proud to be one of the best companies that makes and sells high-quality plant products, such as natural lutein powder. Our cutting-edge facilities and skilled workers make sure that the quality and purity of our goods meet the highest standards. We know a parcel approximately diverse sorts of extraction, like CO2 supercritical extraction, and we take after quality benchmarks from around the world, such as HACCP, GMP, and ISO 9001. To meet the needs of all of our clients, we give a wide extend of administrations, counting contract generation and custom details. Please email us at sales@fairirbiotech.com if you need more information or have a question.

References

1. Johnson, E. J. (2014). Role of lutein and zeaxanthin in visual and cognitive function throughout the lifespan. Nutrition Reviews, 72(9), 605-612.

2. Khoo, H. E., Prasad, K. N., Kong, K. W., Jiang, Y., & Ismail, A. (2011). Carotenoids and their isomers: color pigments in fruits and vegetables. Molecules, 16(2), 1710-1738.

3. Mares, J. (2016). Lutein and zeaxanthin isomers in eye health and disease. Annual Review of Nutrition, 36, 571-602.

4. Nwachukwu, I. D., Udenigwe, C. C., & Aluko, R. E. (2016). Lutein and zeaxanthin: Production technology, bioavailability, mechanisms of action, visual function, and health claim status. Trends in Food Science & Technology, 49, 74-84.

5. Rao, A. V., & Rao, L. G. (2007). Carotenoids and human health. Pharmacological Research, 55(3), 207-216.

6. Zhao, X., Zhang, S., & Pu, Y. (2019). Supercritical fluid extraction of bioactive compounds from plants: A review. Trends in Food Science & Technology, 86, 260-269.

_1751965378790.webp)