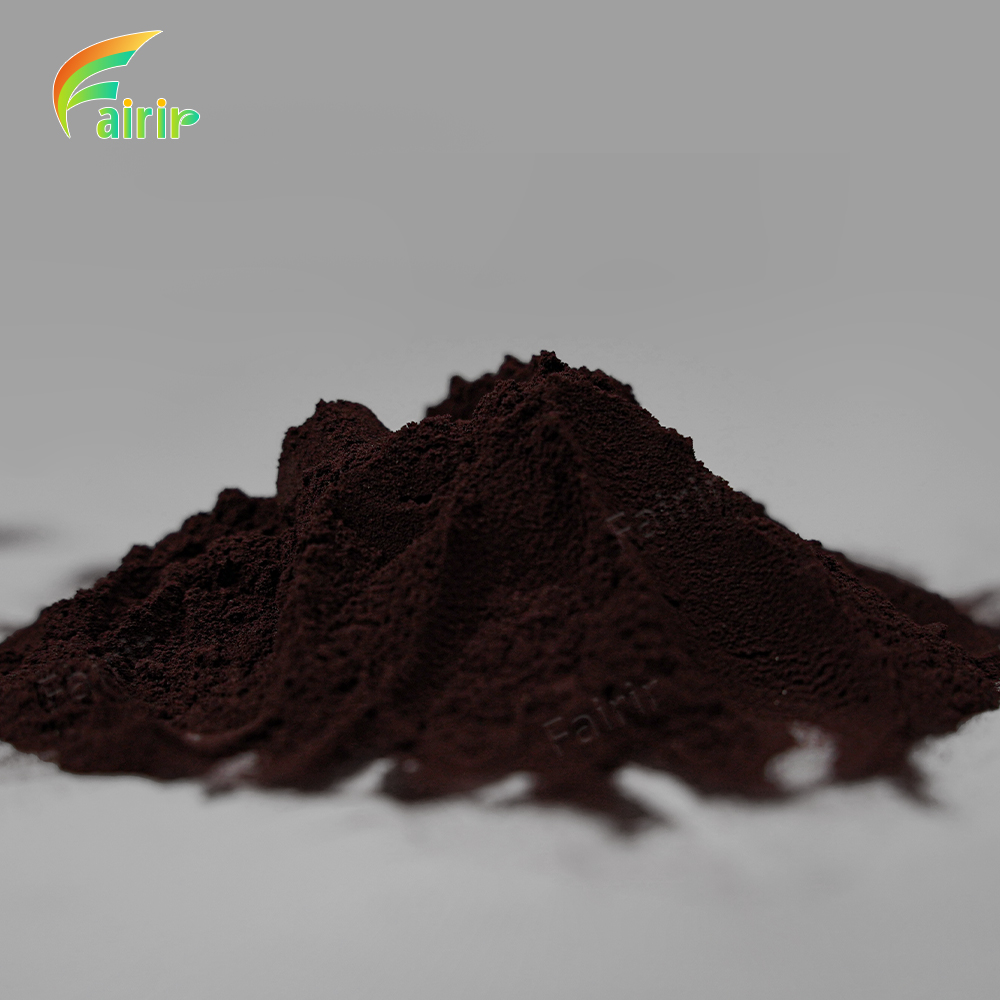

Vitamin E Oil Powder Shelf Life and Storage Conditions

Vitamin E oil powder is a versatile and stable form of vitamin E that has gained popularity in various industries, including pharmaceuticals, nutraceuticals, cosmetics, and food. Understanding the shelf life and proper storage conditions of this valuable ingredient is crucial for maintaining its potency and ensuring its effectiveness in various applications. Vitamin E oil powder offers numerous benefits over its liquid counterpart, including improved stability, easier handling, and enhanced incorporation into diverse formulations. This blog post will delve into the factors affecting the shelf life of vitamin E oil powder, explore optimal storage conditions, and provide insights into maximizing its longevity. By comprehending these aspects, manufacturers, formulators, and consumers can make informed decisions to preserve the quality and efficacy of vitamin E oil powder throughout its lifecycle.

What is the typical shelf life of Vitamin E oil powder?

Factors influencing shelf life

The shelf life of Vitamin E oil powder is influenced by various factors, including its formulation, packaging, and storage conditions. Generally, high-quality Vitamin E oil powder can maintain its potency for 24 to 36 months when stored properly. However, this duration may vary depending on the specific product and manufacturing process. Light, heat, and wetness, among other things, can have a big effect on how stable Vitamin E oil powder is. In addition, the formulation's vitamins and preservatives can help it last longer on the shelf. It is very important for companies that make Vitamin E oil powder to do stability studies to find out how long their goods will last and give customers true expiration dates to make sure they work at their best.

Importance of proper packaging

Proper packaging plays a vital role in preserving the shelf life of Vitamin E oil powder. It is very important to use good packages that keep air out and keep the product safe from light, moisture, and oxygen. A lot of companies choose dark or amber-colored boxes to keep the powder from getting too much light. Aluminum foil bags that are vacuum-sealed are another popular way to package things because they keep things safe from the outside world. As a way to package large amounts of goods, some businesses fill fiber drums with food-safe poly bags. When picking the material and style of packing, you should think about how sensitive the product is to the climate and what it will be used for. Proper packaging not only extends the shelf life of Vitamin E oil powder but also maintains its quality and potency throughout its lifespan.

Impact of storage temperature

Storage temperature significantly affects the shelf life of Vitamin E oil powder. If possible, keep it somewhere cool and dry, away from heat sources and direct sunlight. Usually, 15°C to 25°C (59°F to 77°F) is the best temperature range for keeping. High temperatures can speed up the oxidation and breakdown of Vitamin E molecules, making them less effective and lowering the product's shelf life. Conversely, extremely low temperatures may cause moisture condensation when the product is brought back to room temperature, potentially leading to clumping or degradation. Some manufacturers may recommend refrigeration for certain Vitamin E oil powder formulations to extend their shelf life further. However, it's crucial to follow the specific storage instructions provided by the manufacturer to ensure optimal preservation of the product's quality and efficacy.

How can you extend the shelf life of Vitamin E oil powder?

Proper handling and storage techniques

To extend the shelf life of Vitamin E oil powder, proper handling and storage techniques are essential. Always handle the powder with clean, dry utensils or equipment to prevent contamination. Avoid exposing the product to air for extended periods by promptly closing the container after each use. Store the Vitamin E oil powder in its original packaging or transfer it to an airtight, opaque container if necessary. Keep the storage area clean, dry, and free from pests. Implementing a first-in, first-out (FIFO) inventory system can help ensure that older stock is used before newer batches, minimizing the risk of expired products. To keep the powder's quality throughout its shelf life, it's also important to do regular quality checks and rotate the stock properly.

Use of antioxidants and stabilizers

Incorporating antioxidants and stabilizers into Vitamin E oil powder formulations can significantly extend their shelf life. These extras help keep the Vitamin E molecules from breaking down or oxidizing, so they keep working well over time. Tocopherols, ascorbyl palmitate, and rosemary extract are some of the most common antioxidants found in Vitamin E oil powder. Stabilizers like silicon dioxide or tricalcium phosphate can be added to make the mixture move better and keep it from sticking. When choosing antioxidants and stabilizers, it's important to think about how well they will work with the product and any rules that need to be followed. The right amount of these additives should be used to keep the product working well and make it last longer. Manufacturers often conduct stability studies to determine the optimal combination and concentration of antioxidants and stabilizers for their specific Vitamin E oil powder formulations.

Monitoring and quality control measures

Implementing robust monitoring and quality control measures is crucial for extending the shelf life of Vitamin E oil powder. Testing the product's strength, look, and other important factors on a regular basis can help find any signs of quality problems or decline. Manufacturers should set up a full quality control program that includes tests for stability, microbial analysis, and organoleptic reviews on a regular basis. Using data loggers or weather tracking systems to keep an eye on storage conditions like temperature and humidity can help make sure that the product is always kept in the best conditions. Furthermore, putting in place a tracking system makes it easy to find and fix any quality problems that may appear. To make sure their Vitamin E oil powder goods work until the expiration date, producers can make sure they last as long as possible by using strict quality control measures during production, storage, and distribution.

What are the best storage conditions for Vitamin E oil powder?

Optimal temperature and humidity levels

The best storage conditions for Vitamin E oil powder involve maintaining optimal temperature and humidity levels. As mentioned earlier, the ideal storage temperature range is typically between 15°C to 25°C (59°F to 77°F). It's crucial to avoid temperature fluctuations, as they can lead to moisture condensation and potential degradation of the product. Regarding humidity, Vitamin E oil powder should be stored in a dry environment with relative humidity levels below 60%. High humidity can cause the powder to absorb moisture, leading to clumping and potential microbial growth. Some manufacturers may recommend using desiccants or moisture-absorbing packets within the packaging to maintain low humidity levels. It's essential to monitor both temperature and humidity regularly to ensure that the storage conditions remain within the specified range, thereby preserving the quality and extending the shelf life of the Vitamin E oil powder.

Protection from light and air exposure

Protecting Vitamin E oil powder from light and air exposure is crucial for maintaining its stability and extending its shelf life. Light, especially UV radiation, can accelerate the oxidation of Vitamin E molecules, leading to a loss of potency. To prevent this, store the powder in opaque or amber-colored containers that block out light. If transparent packaging is used, consider storing the product in a dark place or using additional light-protective measures. Air exposure should also be minimized, as oxygen can contribute to the oxidation of Vitamin E. Always keep the container tightly sealed when not in use, and consider using nitrogen flushing or vacuum sealing for bulk storage to remove oxygen from the packaging. Some manufacturers may incorporate oxygen absorbers into their packaging to further protect the Vitamin E oil powder from air exposure. By implementing these protective measures, the shelf life and efficacy of the product can be significantly extended.

Proper container selection and sealing methods

Selecting the appropriate container and sealing method is essential for preserving the quality of Vitamin E oil powder. Materials used to make containers should be safe for the product inside and not damage it when exposed to outside elements. Vitamin E oil powder is usually packed in high-density polyethylene (HDPE) bottles, glass jars with lids that keep air out, or multi-layer layered bags. The container should not let water or light in and should have a tight-sealing device to keep air out. A lot of the time, food-grade liner bags or vacuum-sealed metal foil bags are put inside fiber drums for mass storage. The way the seal is made should create an airtight cover that keeps out contamination and water. Some companies use induction sealing or heat sealing to make a seal that can't be broken and keeps air out. It's also important to think about how easy it is for the end user to use. For example, make sure that the package can be properly packed again after each use to keep the product's quality during its shelf life.

Conclusion

Understanding the shelf life and proper storage conditions of Vitamin E oil powder is crucial for maintaining its quality and efficacy. By implementing optimal storage techniques, using appropriate packaging, and monitoring quality control measures, manufacturers and consumers can significantly extend the product's lifespan. Proper handling, protection from environmental factors, and adherence to recommended storage conditions all contribute to preserving the potency of Vitamin E oil powder. As the demand for this versatile ingredient continues to grow across various industries, maintaining its stability and effectiveness becomes increasingly important. By following the guidelines outlined in this blog, stakeholders can ensure that Vitamin E oil powder remains a reliable and potent ingredient in their formulations.

At Shaanxi Fairir Biotech Co., Ltd., we are committed to providing high-quality Vitamin E oil powder and other plant extracts to meet the diverse needs of our global clientele. Our GMP-certified manufacturing facility, equipped with state-of-the-art technology, ensures consistent quality and purity in every batch. We adhere to strict quality control measures and offer professional services to ensure customer satisfaction. For more information about our products or to discuss your specific requirements, please contact us at sales@fairirbiotech.com. We look forward to partnering with you for mutual success in the world of plant extracts and nutraceuticals.

FAQ

Q: How long does Vitamin E oil powder typically last?

A: High-quality Vitamin E oil powder generally maintains its potency for 24 to 36 months when stored properly.

Q: What is the ideal storage temperature for Vitamin E oil powder?

A: The recommended storage temperature typically ranges from 15°C to 25°C (59°F to 77°F).

Q: Can Vitamin E oil powder be stored in transparent containers?

A: It's best to store Vitamin E oil powder in opaque or amber-colored containers to protect it from light exposure.

Q: How does humidity affect Vitamin E oil powder storage?

A: High humidity can cause the powder to absorb moisture, leading to clumping and potential microbial growth. It's recommended to store in a dry environment with relative humidity below 60%.

Q: What are some common antioxidants used to extend the shelf life of Vitamin E oil powder?

A: Common antioxidants include tocopherols, ascorbyl palmitate, and rosemary extract.

References

1. Johnson, A. R., & Bauernfeind, J. C. (2019). Vitamin E: Food Chemistry, Composition, and Analysis. Marcel Dekker, Inc.

2. Smith, J. L., & Charter, E. (2020). Functional Food Product Development. John Wiley & Sons.

3. Madhavi, D. L., Deshpande, S. S., & Salunkhe, D. K. (2018). Food Antioxidants: Technological, Toxicological, and Health Perspectives. CRC Press.

4. Wildman, R. E. C. (2021). Handbook of Nutraceuticals and Functional Foods. CRC Press.

5. Sabliov, C. M., Chen, H., & Yada, R. Y. (2017). Nanotechnology and Functional Foods: Effective Delivery of Bioactive Ingredients. John Wiley & Sons.

6. Gaonkar, A. G., & McPherson, A. (2019). Ingredient Interactions: Effects on Food Quality. CRC Press.

_1751965378790.webp)