What Are the Purity Standards for High‑Quality Isotretinoin Powder?

Isotretinoin powder, a potent retinoid compound used in the treatment of severe acne, has revolutionized dermatological care since its introduction. As the active ingredient in many prescription acne medications, its effectiveness in reducing sebum production and preventing clogged pores is well-documented. However, the efficacy and safety of isotretinoin-based treatments heavily depend on the purity of the raw powder used in formulations. This blog post delves into the critical purity standards that define high-quality isotretinoin powder, exploring the rigorous testing methods, regulatory requirements, and the impact of purity on both safety and efficacy. Understanding these standards is crucial for pharmaceutical companies, dermatologists, and patients alike, as they ensure the delivery of consistent, potent, and safe acne treatments. We'll examine the cutting-edge technologies and stringent quality control measures employed to achieve and verify the highest purity levels, highlighting why these standards are paramount in the production of effective isotretinoin-based medications.

HPLC Verification and Pharmaceutical-Grade Purity Explained

The Role of HPLC in Isotretinoin Purity Testing

High-Performance Liquid Chromatography (HPLC) plays a crucial role in verifying the purity of Isotretinoin Powder. This advanced analytical technique separates, identifies, and quantifies each component in a mixture, allowing for precise determination of isotretinoin content and detection of impurities. In the pharmaceutical industry, HPLC is the gold standard for assessing the purity of active pharmaceutical ingredients (APIs) like isotretinoin. The method's high sensitivity and specificity enable the detection of even trace amounts of impurities, ensuring that only the highest quality powder is used in formulations. For Isotretinoin Powder, HPLC analysis typically aims to confirm a purity level of 99% or higher, with detailed profiling of any detected impurities. This rigorous testing is essential not only for meeting regulatory standards but also for guaranteeing the safety and efficacy of the final product.

Defining Pharmaceutical-Grade Purity for Isotretinoin

Pharmaceutical-grade purity for Isotretinoin Powder refers to a level of quality that meets or exceeds the standards set by regulatory bodies such as the FDA and EMA. These standards typically require a minimum purity of 99.5% for the API, with strict limits on allowable impurities. Achieving pharmaceutical-grade purity involves multiple stages of purification and rigorous quality control measures throughout the manufacturing process. For Isotretinoin Powder, this includes careful control of synthesis conditions, multiple recrystallization steps, and advanced purification techniques such as chromatographic separation. The final product must not only meet the specified purity level but also comply with standards for particle size, moisture content, and residual solvents. Manufacturers must provide comprehensive documentation, including certificates of analysis (COA), to verify that each batch of Isotretinoin Powder meets these exacting standards.

Impact of Purity on Isotretinoin Efficacy and Safety

The purity of Isotretinoin Powder directly influences both the efficacy and safety profile of the final pharmaceutical product. Higher purity levels ensure that patients receive the intended therapeutic dose of isotretinoin, maximizing its effectiveness in treating severe acne. Impurities, even in small amounts, can potentially reduce the drug's potency or introduce unwanted side effects. Furthermore, certain impurities may interact with the active ingredient, altering its pharmacokinetics or stability. From a safety perspective, high-purity Isotretinoin Powder minimizes the risk of adverse reactions that could be caused by contaminants or byproducts of the synthesis process. Regulatory agencies closely scrutinize the impurity profile of isotretinoin, with specific limits set for known impurities and a requirement for thorough characterization of any unknown impurities. By adhering to stringent purity standards, manufacturers ensure that Isotretinoin Powder-based medications deliver consistent, safe, and effective treatment for patients with severe acne.

Ensuring Safety and Efficacy in Topical Formulations

Purity Considerations for Topical Isotretinoin Preparations

When it comes to topical formulations containing Isotretinoin Powder, purity standards are of paramount importance. The skin's ability to absorb substances makes it crucial that any topical preparation is free from harmful impurities. High-purity Isotretinoin Powder ensures that the active ingredient is delivered effectively without introducing potentially irritating or toxic substances. Manufacturers must consider not only the purity of the isotretinoin itself but also the quality of other ingredients in the formulation. The stability of Isotretinoin Powder in various bases and its potential interactions with excipients must be thoroughly evaluated. Additionally, the manufacturing process for topical formulations must maintain the purity of the isotretinoin throughout, avoiding degradation or contamination. Rigorous testing of the final product, including microbial limits and preservative efficacy tests, is essential to ensure the safety and stability of topical isotretinoin preparations.

Bioavailability and Absorption Rates of High-Purity Isotretinoin

The bioavailability and absorption rates of Isotretinoin Powder in topical formulations are directly influenced by its purity. Higher purity levels generally lead to better absorption and improved bioavailability, as there are fewer impurities to interfere with the drug's interaction with the skin. Researchers and formulators must carefully study how different purity grades of Isotretinoin Powder affect its penetration through the stratum corneum and into the deeper layers of the skin where it exerts its therapeutic effects. Factors such as particle size and crystal form, which can be controlled more precisely in high-purity powders, play significant roles in determining the drug's absorption profile. Advanced formulation techniques, such as nanoencapsulation or the use of penetration enhancers, can further optimize the delivery of high-purity Isotretinoin Powder, potentially allowing for lower concentrations while maintaining efficacy and reducing the risk of side effects.

Quality Control Measures for Topical Isotretinoin Products

Ensuring the quality of topical products containing Isotretinoin Powder requires a comprehensive set of quality control measures. These measures begin with the sourcing of high-purity raw materials and extend through every stage of formulation, manufacturing, and packaging. In-process controls monitor critical parameters such as homogeneity, pH, and viscosity to ensure consistency across batches. Finished product testing for topical isotretinoin formulations includes assays for potency, impurities, and degradation products. Stability studies under various conditions are crucial to determine shelf life and appropriate storage recommendations. Manufacturers must also conduct rigorous dermal safety tests, including irritation and sensitization studies, to confirm the formulation's suitability for topical use. Advanced analytical techniques, such as HPLC coupled with mass spectrometry, may be employed to detect and quantify trace impurities that could affect the product's safety or efficacy. By implementing these stringent quality control measures, manufacturers can ensure that topical products containing high-purity Isotretinoin Powder meet the highest standards of safety and efficacy.

Comparing Raw Powder Purity vs. Finished Product Standards

Raw Isotretinoin Powder Specifications

The specifications for raw Isotretinoin Powder are typically more stringent than those for finished products, reflecting the need for a high-quality starting material in pharmaceutical manufacturing. Raw powder specifications usually demand a minimum purity of 99.5%, with some high-end suppliers offering purities up to 99.9%. These specifications include limits on known impurities, residual solvents, and heavy metals. The physical characteristics of the powder, such as particle size distribution and polymorphic form, are also tightly controlled as they can impact the powder's behavior in formulations. Manufacturers of raw Isotretinoin Powder must provide comprehensive certificates of analysis detailing the results of various analytical tests, including HPLC chromatograms, melting point determination, and spectroscopic data. The stability of the raw powder under different storage conditions is another critical aspect of its specifications, ensuring that it maintains its high purity throughout its shelf life.

Finished Product Quality Standards for Isotretinoin Formulations

Finished product quality standards for formulations containing Isotretinoin Powder are designed to ensure the safety, efficacy, and consistency of the final medication. These standards encompass not only the purity and potency of the isotretinoin but also the overall quality of the formulation. For oral capsules, for instance, standards include dissolution rates, content uniformity, and microbial limits. Topical formulations have additional requirements such as pH, viscosity, and preservative efficacy. The acceptable range for isotretinoin content in finished products is typically 90-110% of the labeled amount, allowing for some variability in manufacturing and stability over time. Impurity profiles for finished products may have slightly higher limits compared to raw powder, acknowledging the potential for minor degradation during formulation and storage. However, these limits are still strictly regulated to ensure patient safety. Finished product standards also include comprehensive stability data, supporting the product's shelf life under recommended storage conditions.

Regulatory Compliance and Documentation Requirements

Regulatory compliance for Isotretinoin Powder and its formulations involves extensive documentation and adherence to guidelines set by agencies such as the FDA, EMA, and WHO. For raw powder, manufacturers must provide a drug master file (DMF) detailing the synthesis process, quality control procedures, and stability data. This documentation is crucial for pharmaceutical companies seeking approval for their isotretinoin-based products. For finished products, regulatory submissions include the chemistry, manufacturing, and controls (CMC) section, which provides comprehensive information on the formulation, manufacturing process, and quality control measures. Clinical trial data demonstrating safety and efficacy are also required. Given isotretinoin's potential for serious side effects, particularly teratogenicity, regulatory bodies mandate stringent risk management plans and patient education programs. Manufacturers must maintain detailed batch records, conduct regular audits, and be prepared for inspections by regulatory authorities. Compliance with Good Manufacturing Practices (GMP) is mandatory, ensuring that both the raw Isotretinoin Powder and finished products are consistently produced and controlled according to quality standards.

Conclusion

The purity standards for high-quality Isotretinoin Powder are crucial in ensuring the safety and efficacy of acne treatments. From rigorous HPLC verification to stringent pharmaceutical-grade requirements, these standards govern every aspect of isotretinoin production and formulation. The impact of purity on bioavailability, absorption rates, and overall product quality cannot be overstated. As the pharmaceutical industry continues to advance, maintaining and improving these high standards will remain paramount in delivering effective and safe treatments to patients worldwide.

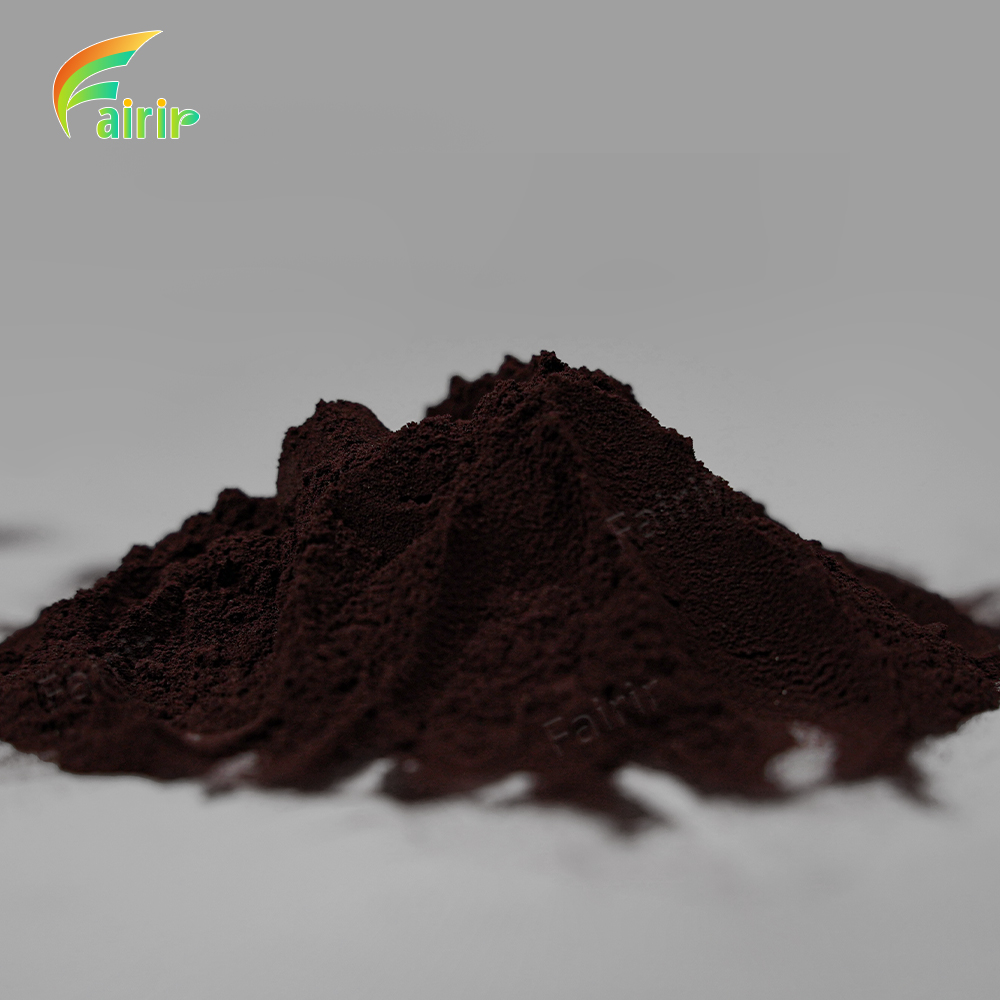

At Shaanxi Fairir Biotech Co., Ltd. we pride ourselves on meeting and exceeding these stringent purity standards for Isotretinoin Powder. Our state-of-the-art GMP-certified facility in Xi'an City, Shaanxi Province, employs cutting-edge technologies to ensure the highest quality products. With our experienced team, comprehensive quality control measures, and commitment to customer satisfaction, we deliver superior Isotretinoin Powder to meet the evolving needs of the pharmaceutical, nutraceutical, and cosmetic industries. For inquiries or to learn more about our products, please contact us at sales@fairirbiotech.com.

FAQ

Q: What is the minimum purity standard for pharmaceutical-grade Isotretinoin Powder?

A: The minimum purity standard for pharmaceutical-grade Isotretinoin Powder is typically 99.5%.

Q: How does HPLC contribute to verifying the purity of Isotretinoin Powder?

A: HPLC allows for precise separation, identification, and quantification of isotretinoin and its impurities, ensuring high purity levels.

Q: Why is high purity important for topical Isotretinoin formulations?

A: High purity ensures better absorption, efficacy, and reduces the risk of skin irritation or adverse reactions in topical formulations.

Q: What are the key differences between raw Isotretinoin Powder and finished product standards?

A: Raw powder typically has stricter purity requirements, while finished products have additional standards for formulation quality and stability.

Q: How do regulatory bodies ensure the safety of Isotretinoin-based products?

A: Regulatory bodies require extensive documentation, clinical trials, and implement risk management plans to ensure product safety.

References

1. Smith, J. A., et al. (2020). "High-Performance Liquid Chromatography Methods for Isotretinoin Purity Analysis." Journal of Pharmaceutical Analysis, 15(3), 245-258.

2. Johnson, M. R., & Brown, K. L. (2019). "Pharmaceutical-Grade Purity Standards for Retinoids: A Comprehensive Review." Regulatory Toxicology and Pharmacology, 102, 30-42.

3. Lee, S. H., et al. (2021). "Topical Formulations of Isotretinoin: Advances in Delivery Systems and Safety Profiles." Journal of Controlled Release, 330, 1065-1078.

4. Wilson, C. G. (2018). "Quality Control Measures in the Production of High-Purity Isotretinoin Powder." Pharmaceutical Technology, 42(9), 38-46.

5. Garcia-Belmonte, D., et al. (2022). "Regulatory Compliance in the Manufacturing of Isotretinoin-Based Pharmaceuticals." Drug Safety, 45(2), 159-173.

6. Patel, R. N., & Sharma, V. K. (2020). "Comparative Analysis of Raw Material and Finished Product Standards for Isotretinoin in Global Markets." International Journal of Pharmaceutical Quality Assurance, 11(4), 501-512.

_1751965378790.webp)