How stable is Beta-Arbutin Powder in skincare formulations?

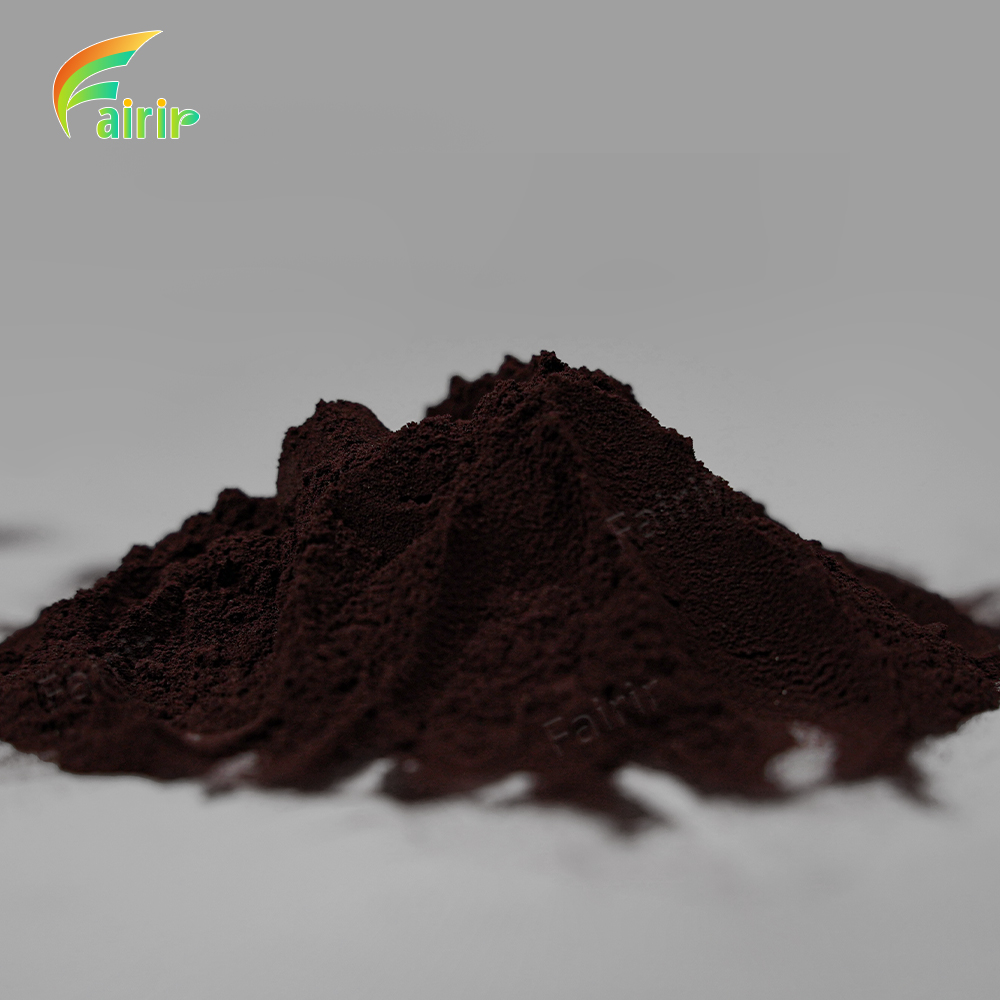

Beta-Arbutin Powder has gained significant attention in the skincare industry for its remarkable skin-lightening properties. As a popular ingredient in various cosmetic formulations, understanding its stability is crucial for both manufacturers and consumers. This naturally derived compound, known for its ability to inhibit melanin production, has become a go-to solution for addressing hyperpigmentation and uneven skin tone. However, the effectiveness of Beta-Arbutin Powder in skincare products largely depends on its stability within different formulations. This blog post delves into the factors affecting the stability of Beta-Arbutin Powder in skincare products, exploring its chemical properties, susceptibility to environmental factors, and the techniques used to enhance its longevity in various formulations. By examining these aspects, we aim to provide valuable insights into the optimal use and storage of Beta-Arbutin Powder-containing skincare products, ensuring maximum efficacy and consumer satisfaction.

What factors influence the stability of Beta-Arbutin Powder in skincare formulations?

PH Levels and Their Impact on Beta-Arbutin Powder Stability

The stability of Beta-Arbutin Powder in skincare formulations is significantly influenced by pH levels. This powerful skin-lightening ingredient performs optimally in slightly acidic to neutral environments, typically within a pH range of 4.0 to 6.5. At these pH levels, Beta-Arbutin Powder maintains its molecular structure and efficacy, ensuring it can effectively inhibit melanin production. However, when exposed to highly acidic or alkaline conditions, Beta-Arbutin Powder can undergo hydrolysis, breaking down into hydroquinone and glucose. This decomposition not only reduces the product's effectiveness but can also lead to potential skin irritation. Therefore, formulators must carefully balance the pH of their skincare products to preserve the integrity of Beta-Arbutin Powder, often using buffer systems to maintain a stable pH throughout the product's shelf life.

Temperature Sensitivity of Beta-Arbutin Powder in Skincare Products

Temperature plays a crucial role in the stability of Beta-Arbutin Powder within skincare formulations. This compound is known to be heat-sensitive, with its stability decreasing as temperatures rise. Prolonged exposure to high temperatures can accelerate the breakdown of Beta-Arbutin Powder, potentially leading to a loss of its skin-lightening properties. Ideally, products containing Beta-Arbutin Powder should be stored at room temperature or below, typically between 15°C and 25°C (59°F to 77°F). Manufacturers often incorporate temperature-resistant packaging and recommend proper storage conditions to consumers to maintain the product's efficacy. Additionally, during the formulation process, manufacturers may use cold processing techniques or add stabilizing agents to enhance the temperature resistance of Beta-Arbutin Powder, ensuring its stability throughout the product's shelf life.

Light Exposure and Its Effects on Beta-Arbutin Powder Stability

Light exposure is another critical factor affecting the stability of Beta-Arbutin Powder in skincare formulations. This compound is photosensitive, meaning it can degrade when exposed to light, particularly UV radiation. When Beta-Arbutin Powder breaks down due to light exposure, it not only loses its skin-lightening efficacy but can also form potentially harmful byproducts. To mitigate this issue, manufacturers often package Beta-Arbutin Powder-containing products in opaque or dark-colored containers that block out light. Some formulations may also include UV filters or antioxidants to further protect the Beta-Arbutin Powder from light-induced degradation. Consumers are typically advised to store these products in dark, cool places and avoid direct sunlight exposure to maintain the product's stability and effectiveness over time.

How does the formulation process affect the stability of Beta-Arbutin Powder?

Importance of Proper Mixing Techniques for Beta-Arbutin Powder Stability

The formulation process plays a crucial role in maintaining the stability of Beta-Arbutin Powder in skincare products. Proper mixing techniques are essential to ensure that the Beta-Arbutin Powder is evenly distributed throughout the formulation without compromising its molecular structure. Gentle mixing methods, such as low-shear mixing or cold processing, are often preferred to minimize the risk of degradation. Additionally, the order of ingredient incorporation can significantly impact stability. For instance, adding Beta-Arbutin Powder to the water phase before oil-soluble ingredients can help protect it from potential oxidation. Formulators must also consider the compatibility of Beta-Arbutin Powder with other ingredients, as certain combinations may lead to instability or reduced efficacy. By carefully controlling the mixing process and ingredient interactions, manufacturers can significantly enhance the stability of Beta-Arbutin Powder in their skincare formulations.

Role of Preservatives in Maintaining Beta-Arbutin Powder Stability

Preservatives play a vital role in maintaining the stability of Beta-Arbutin Powder in skincare formulations. While Beta-Arbutin Powder itself is not particularly prone to microbial growth, the water-based nature of many skincare products creates an environment conducive to bacterial and fungal proliferation. The presence of microorganisms can lead to the breakdown of Beta-Arbutin Powder, reducing its effectiveness and potentially causing skin irritation. Carefully selected preservatives can protect the formulation from microbial contamination without interfering with the stability or efficacy of Beta-Arbutin Powder. Broad-spectrum preservatives that are effective at the product's pH level are often chosen. Some formulators opt for natural preservative systems that align with clean beauty trends while still ensuring product stability. The choice and concentration of preservatives must be balanced to provide adequate protection without causing sensitivity issues for consumers.

Impact of Packaging on Beta-Arbutin Powder Stability in Skincare Products

The choice of packaging significantly influences the long-term stability of Beta-Arbutin Powder in skincare formulations. As Beta-Arbutin Powder is sensitive to light and air exposure, packaging plays a crucial role in protecting the ingredient from these degrading factors. Airless pump bottles or tubes are often preferred as they minimize air contact with the product, reducing oxidation risks. For products with higher water content, packaging with good barrier properties against moisture loss is essential to prevent concentration changes that could affect stability. Some manufacturers opt for multi-layered packaging or use special coatings to enhance protection against external factors. The material of the packaging itself is also important; certain plastics may interact with the formulation, potentially affecting the stability of Beta-Arbutin Powder. By selecting appropriate packaging, manufacturers can significantly extend the shelf life and maintain the efficacy of Beta-Arbutin Powder-containing skincare products.

What are the best practices for ensuring Beta-Arbutin Powder stability in skincare products?

Optimal Storage Conditions for Beta-Arbutin Powder-Containing Skincare Products

Ensuring optimal storage conditions is crucial for maintaining the stability of Beta-Arbutin Powder in skincare products. Ideally, these products should be stored in a cool, dark place away from direct sunlight and heat sources. The recommended temperature range is typically between 15°C and 25°C (59°F to 77°F). Avoiding temperature fluctuations is also important, as repeated heating and cooling cycles can degrade the Beta-Arbutin Powder over time. Humidity control is another factor to consider, as excess moisture can promote microbial growth and potentially affect the product's stability. Manufacturers often include storage instructions on product labels, and educating consumers about proper storage practices can significantly contribute to maintaining the product's efficacy throughout its intended shelf life. Some companies are even exploring innovative packaging solutions, such as temperature-indicating labels, to help consumers ensure their products are stored under optimal conditions.

Importance of Quality Control in Beta-Arbutin Powder Formulations

Rigorous quality control measures are essential for ensuring the stability of Beta-Arbutin Powder in skincare formulations. This process begins with the sourcing of high-quality raw materials and extends throughout the manufacturing process. Regular testing of Beta-Arbutin Powder purity and potency is crucial, as variations can significantly impact the final product's stability and efficacy. During formulation, strict adherence to standardized procedures and careful monitoring of environmental conditions help maintain consistency. Stability testing under various conditions (temperature, light exposure, etc.) is typically conducted to assess the product's shelf life and identify potential issues. Advanced analytical techniques, such as HPLC (High-Performance Liquid Chromatography), are often employed to monitor the concentration and stability of Beta-Arbutin Powder over time. By implementing comprehensive quality control measures, manufacturers can ensure that their Beta-Arbutin Powder-containing products maintain their intended properties throughout their shelf life, providing consumers with effective and reliable skincare solutions.

Innovative Formulation Techniques to Enhance Beta-Arbutin Powder Stability

As the skincare industry evolves, innovative formulation techniques are being developed to enhance the stability of Beta-Arbutin Powder in various products. One approach is the use of microencapsulation, where Beta-Arbutin Powder is enclosed within tiny capsules that protect it from environmental factors and control its release. This technique can significantly improve stability and extend the product's shelf life. Another innovative method is the incorporation of Beta-Arbutin Powder into liposomal delivery systems, which not only enhances stability but also improves skin penetration and efficacy. Some formulators are exploring the use of natural stabilizers, such as certain plant extracts or vitamins, that can synergistically work with Beta-Arbutin Powder to maintain its integrity. Additionally, advanced emulsion technologies are being employed to create more stable formulations that can better protect sensitive ingredients like Beta-Arbutin Powder. These innovative approaches not only enhance product stability but also often lead to improved performance and consumer satisfaction.

Conclusion

The stability of Beta-Arbutin Powder in skincare formulations is a complex issue influenced by various factors, including pH levels, temperature, light exposure, and formulation techniques. By understanding these factors and implementing best practices in formulation, packaging, and storage, manufacturers can significantly enhance the stability and efficacy of Beta-Arbutin Powder-containing products. As the skincare industry continues to evolve, innovative approaches to ingredient stability will play a crucial role in developing more effective and longer-lasting products, ultimately benefiting consumers seeking reliable skin-lightening solutions.

Discover Premium Beta-Arbutin Powder for Your Formulations Today!

Shaanxi Fairir Biotech Co., Ltd. is proud to be a leading manufacturer and supplier of high-quality plant extracts, including Beta-Arbutin Powder. Our state-of-the-art facilities, including a 10,000㎡ GMP-certified production plant and advanced extraction technologies, ensure the highest quality and purity of our products. With a professional R&D team and comprehensive quality management system, we are committed to meeting the evolving needs of the pharmaceutical, nutraceutical, cosmetic, and food industries. For more information about our Beta-Arbutin Powder and other plant extracts, please contact us at sales@fairirbiotech.com.

References

1. Kim, Y. J., & Uyama, H. (2005). Tyrosinase inhibitors from natural and synthetic sources: structure, inhibition mechanism, and perspective for the future. Cellular and Molecular Life Sciences, 62(15), 1707-1723.

2. Boissy, R. E., Visscher, M., & DeLong, M. A. (2005). DeoxyArbutin: a novel reversible tyrosinase inhibitor with effective in vivo skin lightening potency. Experimental Dermatology, 14(8), 601-608.

3. Sugimoto, K., Nishimura, T., Nomura, K., Sugimoto, K., & Kuriki, T. (2004). Inhibitory effects of α-arbutin on melanin synthesis in cultured human melanoma cells and a three-dimensional human skin model. Biological and Pharmaceutical Bulletin, 27(4), 510-514.

4. Hu, Z. M., Zhou, Q., Lei, T. C., Ding, S. F., & Xu, S. Z. (2009). Effects of hydroquinone and its glucoside derivatives on melanogenesis and antioxidation: Biosafety as skin whitening agents. Journal of Dermatological Science, 55(3), 179-184.

5. Maeda, K., & Fukuda, M. (1996). Arbutin: mechanism of its depigmenting action in human melanocyte culture. Journal of Pharmacology and Experimental Therapeutics, 276(2), 765-769.

6. Seo, D. H., Jung, J. H., Lee, J. E., Jeon, E. J., Kim, W., & Park, C. S. (2012). Biotechnological production of arbutins (α-and β-arbutins), skin-lightening agents, and their derivatives. Applied Microbiology and Biotechnology, 95(6), 1417-1425.

_1751965378790.webp)