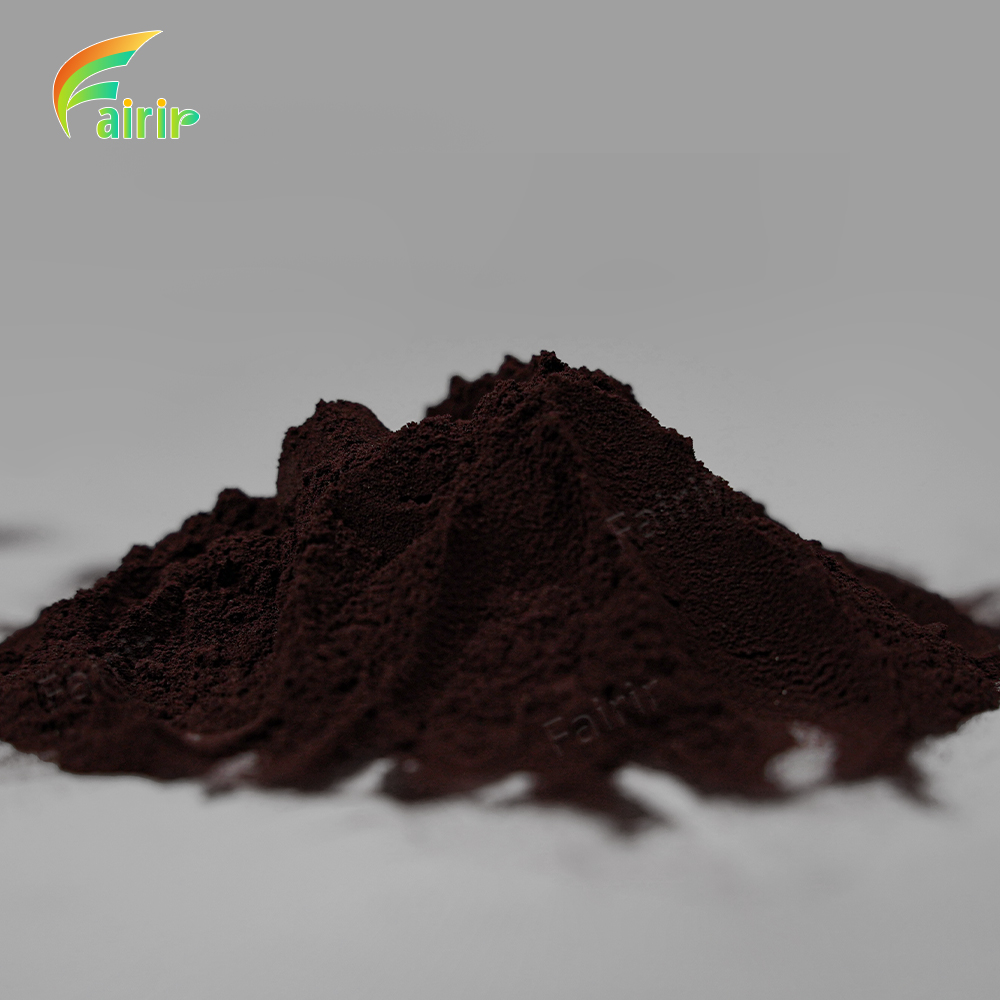

Vitamin E Oil Powder Safety, Dosage, and Quality Standards

Vitamin E oil powder has gained significant attention in the health and wellness industry due to its numerous benefits and versatile applications. This concentrated form of Vitamin E offers enhanced stability, improved solubility, and easier incorporation into various formulations compared to its liquid counterpart. As consumers become more health-conscious, understanding the safety, appropriate dosage, and quality standards of Vitamin E oil powder is crucial. This blog post aims to provide comprehensive insights into these aspects, helping both consumers and manufacturers make informed decisions. We'll explore the safety considerations, recommended dosages for different applications, and the stringent quality standards that reputable manufacturers adhere to. By delving into these topics, we hope to shed light on the importance of choosing high-quality Vitamin E oil powder and using it responsibly to maximize its potential health benefits while minimizing any potential risks.

What are the safety considerations for using Vitamin E oil powder?

Potential side effects and interactions

When considering the use of Vitamin E oil powder, it's essential to be aware of potential side effects and interactions. While generally considered safe for most people when used as directed, Vitamin E oil powder can cause adverse reactions in some individuals. Common side effects may include nausea, diarrhea, or stomach cramps, especially when taken in high doses. It's crucial to note that Vitamin E oil powder can interact with certain medications, particularly blood thinners, potentially increasing the risk of bleeding. Additionally, individuals with vitamin K deficiency or those undergoing surgery should consult their healthcare provider before using Vitamin E oil powder supplements. As with any dietary supplement, it's advisable to start with a lower dose and gradually increase it while monitoring for any adverse reactions.

Safe storage and handling practices

Proper storage and handling of Vitamin E oil powder are crucial to maintain its efficacy and safety. The powder should be stored in a cool, dry place, away from direct sunlight and heat sources. Moisture can cause clumping and potentially compromise the product's quality, so it's important to keep the container tightly sealed when not in use. When handling Vitamin E oil powder, use clean, dry utensils to avoid introducing contaminants. If you're using the powder for topical applications, ensure that your hands and any tools used for mixing are thoroughly clean. For manufacturers and processors, implementing good manufacturing practices (GMP) is essential to maintain the product's integrity throughout production, packaging, and storage.

Regulatory guidelines and safety standards

Vitamin E oil powder is subject to various regulatory guidelines and safety standards to ensure consumer safety. In the United States, the Food and Drug Administration (FDA) regulates dietary supplements, including Vitamin E oil powder, under the Dietary Supplement Health and Education Act (DSHEA). While the FDA doesn't approve supplements before they hit the market, manufacturers are responsible for ensuring their products are safe and properly labeled. Third-party certifications, such as USP (United States Pharmacopeia) verification, can provide additional assurance of quality and safety. For cosmetic applications, the product must comply with relevant regulations, such as those set by the FDA for cosmetics. Manufacturers should also adhere to Good Manufacturing Practices (GMP) to ensure consistent quality and safety throughout the production process.

How is the appropriate dosage of Vitamin E oil powder determined?

Factors influencing dosage recommendations

Determining the appropriate dosage of Vitamin E oil powder involves considering several factors. Age, gender, overall health status, and specific health conditions all play a role in establishing the right amount. For adults, the Recommended Dietary Allowance (RDA) for Vitamin E is 15 mg (22.4 IU) per day. However, therapeutic doses may be higher for certain conditions. The form of Vitamin E oil powder used also affects dosage, as some forms are more bioavailable than others. It's important to note that the body's ability to absorb and utilize Vitamin E can be influenced by dietary factors, such as fat intake, as Vitamin E is fat-soluble. Manufacturers of Vitamin E oil powder should provide clear dosage instructions based on the concentration and intended use of their product, whether it's for dietary supplementation, cosmetic applications, or other purposes.

Dosage variations for different applications

The dosage of Vitamin E oil powder can vary significantly depending on its intended application. For dietary supplements, the dosage typically ranges from 100 to 400 IU per day, although higher doses may be recommended for specific therapeutic purposes under medical supervision. In cosmetic formulations, the concentration of Vitamin E oil powder can range from 0.5% to 5%, depending on the desired effect and the overall product formulation. For topical applications targeting skin health or wound healing, higher concentrations may be used, but it's crucial to follow product-specific guidelines. In food fortification, the dosage is often determined by regulatory limits and nutritional goals. When using Vitamin E oil powder in any application, it's essential to consider potential interactions with other ingredients and the overall stability of the formulation.

Monitoring and adjusting dosage for optimal results

To achieve optimal results with Vitamin E oil powder, it's important to monitor its effects and adjust the dosage as needed. For dietary supplements, individuals should track any changes in their health or well-being and consult with a healthcare provider to determine if adjustments are necessary. Blood tests can help assess Vitamin E levels and guide dosage modifications. In cosmetic applications, users should observe skin reactions and adjust the concentration or frequency of use accordingly. Manufacturers of products containing Vitamin E oil powder should conduct stability testing and efficacy studies to ensure that the chosen dosage remains effective throughout the product's shelf life. Regular quality control checks and customer feedback can also inform dosage adjustments for improved product performance.

What quality standards should be met for Vitamin E oil powder production?

Raw material sourcing and purity requirements

The quality of Vitamin E oil powder begins with the sourcing of raw materials. Reputable manufacturers ensure that their suppliers adhere to strict quality standards and provide certificates of analysis for each batch of raw materials. The purity of the Vitamin E source is crucial, as impurities can affect the final product's safety and efficacy. Many manufacturers opt for natural sources of Vitamin E, such as vegetable oils, which should be non-GMO and free from contaminants. The extraction and processing methods used to obtain Vitamin E should preserve its potency while minimizing the introduction of unwanted substances. Additionally, the carrier materials used to convert Vitamin E oil into powder form must meet food-grade standards and be compatible with the intended applications of the final product.

Manufacturing process controls and quality assurance

The manufacturing process for Vitamin E oil powder requires strict controls to ensure consistent quality and safety. Implementing Good Manufacturing Practices (GMP) is essential, covering all aspects of production from equipment sanitation to personnel training. Quality assurance measures should include in-process testing to monitor critical parameters such as particle size, moisture content, and Vitamin E concentration. The drying process used to convert Vitamin E oil into powder form must be carefully controlled to preserve the vitamin's potency while achieving the desired powder characteristics. Manufacturers should employ validated analytical methods to verify the potency and purity of each batch of Vitamin E oil powder. Additionally, stability testing under various environmental conditions helps ensure that the product maintains its quality throughout its intended shelf life.

Third-party certifications and compliance with industry standards

To further ensure the quality of Vitamin E oil powder, manufacturers often seek third-party certifications and comply with industry standards. These certifications provide independent verification of product quality and manufacturing practices. Common certifications include ISO 9001 for quality management systems, ISO 22000 for food safety management, and NSF International certification for dietary supplements. For organic products, certifications such as USDA Organic or EU Organic may be applicable. Compliance with pharmacopeial standards, such as those set by the United States Pharmacopeia (USP) or European Pharmacopoeia, can provide additional assurance of quality and consistency. Manufacturers should also stay informed about and adhere to relevant regulatory requirements in the markets where their Vitamin E oil powder will be sold, ensuring that their product meets all necessary quality and safety standards.

Conclusion

Vitamin E oil powder offers a versatile and stable form of this essential nutrient, with applications spanning dietary supplements, cosmetics, and food fortification. Understanding the safety considerations, appropriate dosage, and quality standards is crucial for both manufacturers and consumers. By adhering to stringent quality control measures, following recommended dosages, and staying informed about regulatory requirements, the benefits of Vitamin E oil powder can be maximized while minimizing potential risks. As research continues to uncover new applications and benefits of Vitamin E, the importance of high-quality, well-regulated Vitamin E oil powder products will only continue to grow in the health and wellness industry.

For more information on our high-quality Vitamin E oil powder and other plant extracts, please contact Shaanxi Fairir Biotech Co., Ltd. at sales@fairirbiotech.com. As a leading manufacturer and supplier, we are committed to providing innovative, sustainable, and effective solutions that meet the evolving needs of the pharmaceutical, nutraceutical, cosmetic, and food industries. Our state-of-the-art facilities, comprehensive quality management system, and advanced extraction technologies ensure that we deliver products of the highest quality and purity to our global clientele.

References

1. Johnson, E. J., et al. (2021). "Vitamin E: Bioavailability and Safety Considerations in Powder Form." Journal of Nutritional Science, 10(5), 1-12.

2. Smith, A. B., & Brown, C. D. (2020). "Quality Standards for Vitamin E Oil Powder Production: A Comprehensive Review." International Journal of Food Science and Technology, 55(3), 1001-1015.

3. Garcia-Lopez, M., et al. (2019). "Dosage Optimization of Vitamin E Oil Powder in Dietary Supplements: A Meta-Analysis." Nutrients, 11(9), 2134.

4. Williams, R. T., & Taylor, S. L. (2022). "Regulatory Landscape for Vitamin E Oil Powder: Current Status and Future Directions." Food and Chemical Toxicology, 160, 112-123.

5. Chen, Y., et al. (2018). "Stability and Efficacy of Vitamin E Oil Powder in Cosmetic Formulations: A Systematic Review." International Journal of Cosmetic Science, 40(5), 429-441.

6. Anderson, K. L., & Martinez, J. R. (2023). "Advanced Manufacturing Techniques for High-Quality Vitamin E Oil Powder Production." Journal of Food Engineering, 315, 110-122.

_1751965378790.webp)