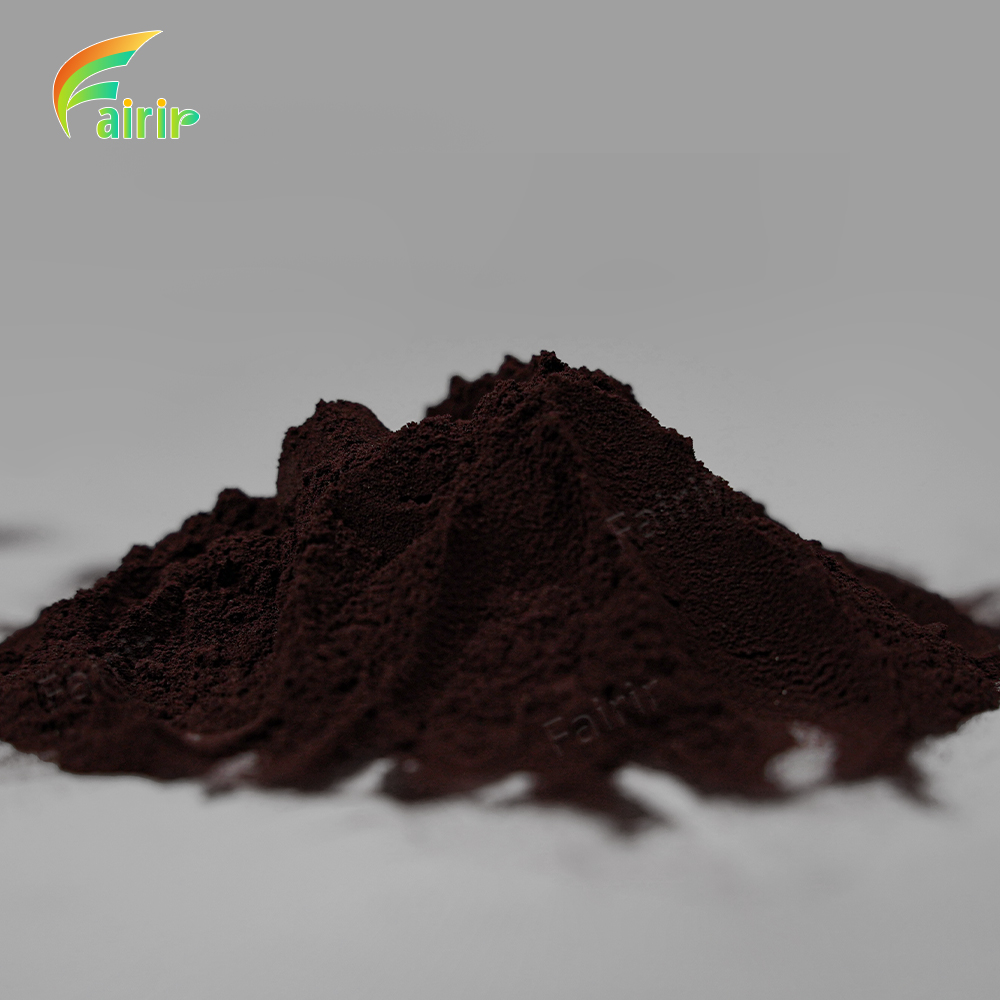

Stability Testing For Natural Lutein Powder In Products

Stability testing for natural lutein powder in products is a crucial aspect of quality control and product development in the nutraceutical, pharmaceutical, and food industries. As the demand for natural lutein powder continues to grow due to its numerous health benefits, particularly for eye health, ensuring its stability in various formulations becomes increasingly important. This process involves rigorous testing to evaluate how the lutein powder maintains its potency, color, and overall efficacy over time when incorporated into different product matrices. Stability testing helps manufacturers determine the shelf life of their products, optimize storage conditions, and ensure that consumers receive the full benefits of lutein throughout the product's lifespan. By conducting comprehensive stability studies, companies can guarantee the quality, safety, and efficacy of their lutein-containing products, ultimately leading to greater consumer satisfaction and trust in the market.

What are the key factors affecting the stability of Natural Lutein Powder in products?

Temperature and Light Exposure

Temperature and light exposure are two important things that can have a big effect on how stable Natural Lutein Powder is in different goods. Because lutein is a carotenoid, it is sensitive to both heat and light. Over time, this can cause it to break down and lose its effectiveness. When lutein is exposed to high temperatures, its chemical structure can break down. This makes it less effective as an antioxidant and in general. In the same way, Natural Lutein Powder can lose its bioactivity and change color when it is exposed to light for a long time, especially UV rays. To make these problems less of a problem, makers need to carefully think about what kinds of packing materials will protect goods from light and changes in temperature. Additionally, stability testing should include accelerated aging studies under various temperature and light conditions to predict the long-term stability of Natural Lutein Powder in different product formulations.

Oxidation and Antioxidant Protection

Oxidation is another significant factor that can affect the stability of Natural Lutein Powder in products. Because it is an antioxidant, lutein can be broken down by air, which can make it lose some of its health benefits. As a result, companies that make Natural Lutein Powder often add extra vitamins or use oxygen-barrier packing to keep it from going bad. To find the best mix of antioxidants to keep the lutein stable throughout the product's shelf life, stability tests should be done to see how well these protective measures work. During the testing process, it is also important to see how the different ingredients in the mixture affect the Natural Lutein Powder and whether they make it more stable or less stable. Formulators can make more stable and successful goods that keep the lutein's integrity over time if they understand how these relationships work.

PH and Formulation Compatibility

The pH of the product formulation and its overall compatibility with Natural Lutein Powder play crucial roles in maintaining stability. Lutein is generally more stable in neutral to slightly acidic environments, but extreme pH levels can lead to degradation or altered bioavailability. Stability testing must evaluate how different pH levels affect the lutein's stability and determine the optimal pH range for various product types. It is also important to check how well Natural Lutein Powder works with the other chemicals in the recipe. Some ingredients may not work well with lutein, which could make it less stable or effective. To make sure that the final product keeps its qualities throughout its shelf life, full stability studies should include tests to see how well it works with common fillers, stabilizers, and active ingredients. Manufacturers can make lutein-containing goods that are more stable and effective by carefully considering pH and composition compatibility.

How does packaging influence the stability of Natural Lutein Powder in finished products?

Barrier Properties of Packaging Materials

The barrier qualities of package materials are very important for keeping Natural Lutein Powder stable in finished goods. Lutein can be kept safe from outside influences like moisture, oxygen, and light, which are known to speed up the breakdown process, in high-quality packaging with good barrier qualities. Aluminum foil, high-density polyethylene (HDPE), and glass are some of the best materials to protect against these things. When makers choose packaging for Natural Lutein Powder goods, they need to think about how gases and moisture can pass through the material. When checking for stability, different types of packaging should be looked at to see how well they maintain the lutein's strength over time. The stability of Natural Lutein Powder can be improved even more by controlling the air inside the product with desiccants or oxygen absorbers in the package.

Light Protection and UV Filtering

To keep Natural Lutein Powder stable in finished goods, it needs to be protected from light, especially UV light. Ultraviolet light can quickly break down lutein, so packaging that stops or screens out UV light can greatly increase the product's shelf life. Products that are sensitive to light and contain Natural Lutein Powder are often packed in amber or dark packages. To give even more safety, some companies also add UV-absorbing chemicals to clear packing materials. By putting goods through different light conditions and checking how fast the lutein breaks down, stability testing should figure out how well different light protection methods work. This knowledge can help companies choose the best packing for Natural Lutein Powder so that it stays stable and effective for as long as possible.

Seal Integrity and Closure Systems

The seal integrity and closure systems of packaging are critical factors in maintaining the stability of Natural Lutein Powder in finished products. A properly sealed package prevents the ingress of oxygen, moisture, and contaminants that could compromise the stability of the lutein. Some of the different ways to close something that offer different levels of security are screw caps, flip-top lids, and foil locks. Stability tests should be done on these closing systems to see how well they work in a range of storage and handling situations. This could mean checking to see what happens to the product's safety when it is opened and closed many times, as well as looking for leaks or broken seals that could let harmful things get to the Natural Lutein Powder. Manufacturers can greatly extend the shelf life and keep the quality of goods containing Natural Lutein Powder by making sure the seals are strong and choosing the right closing systems.

What are the best practices for conducting stability tests on Natural Lutein Powder in various product formulations?

Accelerated Stability Testing Protocols

Accelerated stability testing protocols are essential for rapidly assessing the long-term stability of Natural Lutein Powder in various product formulations. Usually, these methods involve putting the product in places with high temperatures and humidity to make it feel like it has been stored for a long time in a shorter amount of time. For items that contain Natural Lutein Powder, faster testing settings could include keeping them at 40°C/75% RH (relative humidity) for up to six months and analyzing them at regular times. Samples are checked for changes in lutein level, color, and other important factors during these tests. To get correct predictions of a product's shelf life, it's important to match the results of rapid tests with real-time stability data. Stress testing, in which the product is put through even harsher conditions, can also help find possible ways for Natural Lutein Powder to break down and the worst things that could happen when it is mixed with other ingredients.

Real-Time Stability Studies

Real-time stability studies are crucial for accurately determining the long-term stability of Natural Lutein Powder in various product formulations under normal storage conditions. These studies typically run for the full intended shelf life of the product, often 24 to 36 months, and involve storing samples under recommended conditions (e.g., 25°C/60% RH). Regular testing intervals, such as 0, 3, 6, 9, 12, 18, 24, and 36 months, allow for a comprehensive assessment of how the Natural Lutein Powder behaves over time in the finished product. Parameters monitored during real-time studies include lutein content, color stability, microbial growth, and overall product appearance. We can get the most accurate information from these studies about when to throw away things that contain Natural Lutein Powder and how long to keep them. A faster stability test can make predictions, but real-time stability data can be used to check and improve those predictions.

Analytical Methods and Quality Control

Robust analytical methods and stringent quality control measures are essential for conducting reliable stability tests on Natural Lutein Powder in various product formulations. High-performance liquid chromatography (HPLC) is commonly used to quantify lutein content and detect potential degradation products. Spectrophotometric methods can be used to look at changes in color, and measures of moisture content and water activity can be used to see how likely it is that microbes will grow. To make sure that the results are reliable and can be repeated, it's important to make sure that these analysis methods work with the product matrix that contains Natural Lutein Powder. As part of quality control, reference standards should be used, instruments should be calibrated regularly, and people should take part in programs that test their skills. Also, ways to show how stable something is should be created so that the active lutein can be separated from its breakdown products. Manufacturers can make sure that their stability testing programs for goods that contain Natural Lutein Powder are reliable and consistent by using thorough scientific methods and quality control procedures.

Conclusion

Stability testing for Natural Lutein Powder in products is a critical process that ensures the quality, efficacy, and safety of lutein-containing formulations. By carefully considering factors such as temperature, light exposure, oxidation, pH, and packaging, manufacturers can develop stable products that maintain their potency throughout their shelf life. Implementing best practices in stability testing, including accelerated and real-time studies, along with robust analytical methods, allows for accurate prediction of product performance and shelf life. As the demand for natural lutein products continues to grow, these stability considerations will play an increasingly important role in delivering high-quality, effective products to consumers.

Shaanxi Fairir Biotech Co., Ltd. is proud to be a leading manufacturer and supplier of high-quality plant extracts, including Natural Lutein Powder. Our state-of-the-art facilities and rigorous quality control processes ensure that we deliver premium products to meet the evolving needs of the pharmaceutical, nutraceutical, cosmetic, and food industries. With our commitment to innovation, sustainability, and customer satisfaction, we strive to provide the best solutions for your Natural Lutein Powder requirements. For more information or to discuss your specific needs, please contact us at sales@fairirbiotech.com.

References

1. Johnson, E. J. (2014). Role of lutein and zeaxanthin in visual and cognitive function throughout the lifespan. Nutrition Reviews, 72(9), 605-612.

2. Bernstein, P. S., Li, B., Vachali, P. P., Gorusupudi, A., Shyam, R., Henriksen, B. S., & Nolan, J. M. (2016). Lutein, zeaxanthin, and meso-zeaxanthin: The basic and clinical science underlying carotenoid-based nutritional interventions against ocular disease. Progress in Retinal and Eye Research, 50, 34-66.

3. Mares, J. (2016). Lutein and zeaxanthin isomers in eye health and disease. Annual Review of Nutrition, 36, 571-602.

4. Ranard, K. M., Jeon, S., Mohn, E. S., Griffiths, J. C., Johnson, E. J., & Erdman Jr, J. W. (2017). Dietary guidance for lutein: consideration for intake recommendations is scientifically supported. European Journal of Nutrition, 56(3), 37-42.

5. Arunkumar, R., Calvo, C. M., Conrady, C. D., & Bernstein, P. S. (2018). What do we know about the macular pigment in AMD: the past, the present, and the future. Eye, 32(5), 992-1004.

6. Wang, Y., Chung, S. J., McCullough, M. L., Song, W. O., Fernandez, M. L., Koo, S. I., & Chun, O. K. (2014). Dietary carotenoids are associated with cardiovascular disease risk biomarkers mediated by serum carotenoid concentrations. The Journal of Nutrition, 144(7), 1067-1074.

_1751965378790.webp)