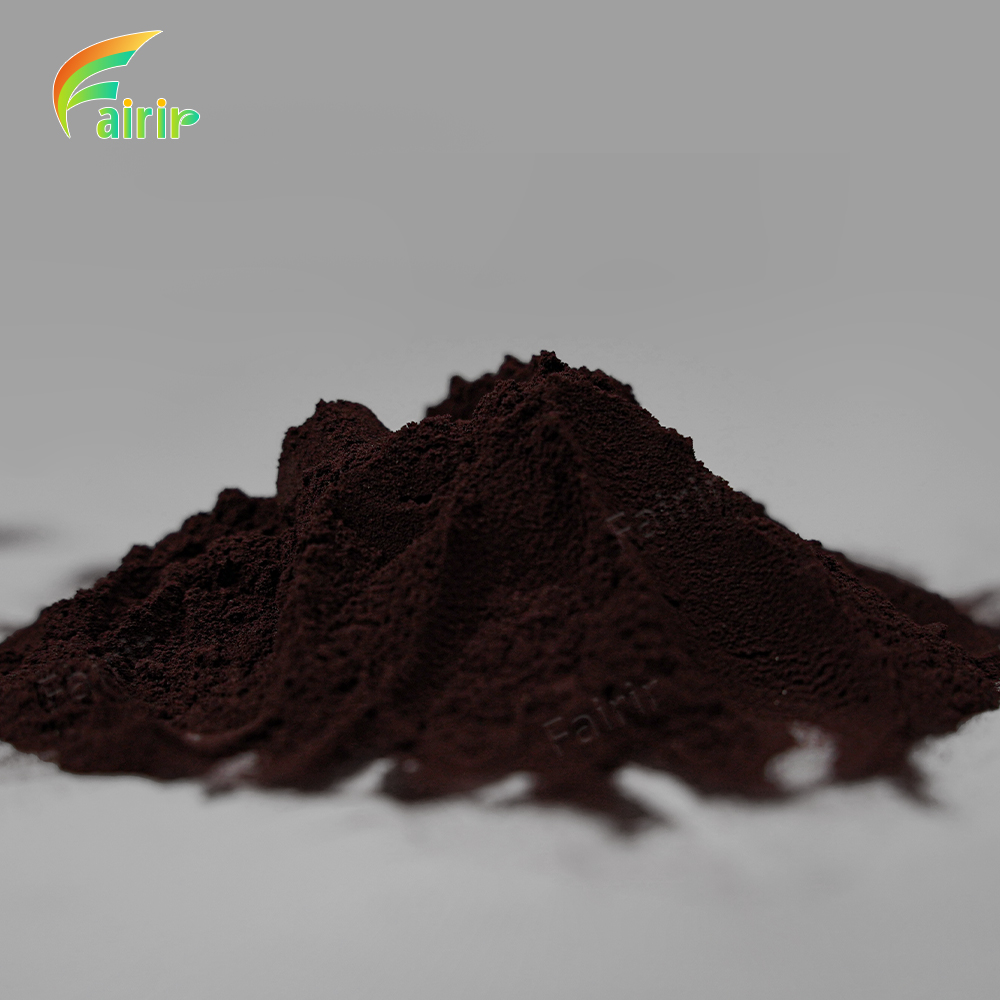

Stevioside Powder Solubility And Formulation Guidelines

Stevioside powder, a natural sweetener derived from the Stevia rebaudiana plant, has gained significant attention in the food and beverage industry due to its zero-calorie profile and intense sweetness. Understanding the solubility and formulation guidelines of stevioside powder is crucial for manufacturers and product developers looking to incorporate this versatile ingredient into their products. This blog post aims to provide comprehensive insights into the solubility characteristics of stevioside powder and offer practical guidelines for its effective formulation in various applications. We will explore the factors affecting stevioside solubility, discuss optimal dissolution techniques, and present strategies for overcoming common formulation challenges. Additionally, we'll delve into the importance of proper pH management, temperature control, and compatibility with other ingredients to ensure successful integration of stevioside powder in diverse product matrices. By following these solubility and formulation guidelines, formulators can maximize the potential of stevioside powder and create high-quality, consumer-friendly products that meet the growing demand for natural, low-calorie sweetening solutions.

What are the key factors affecting stevioside powder solubility?

Temperature and its impact on stevioside dissolution

The temperature is very important for how well stevioside powder dissolves. Stevioside usually dissolves better when it's warmer, just like many other chemicals. When the temperature goes up, the fluid molecules' kinetic energy goes up, which makes it easier for them to break the bonds between molecules in the stevioside powder. This increased molecular movement speeds up the breakdown process and lets more stevioside molecules mix with the solvent. But it's important to keep in mind that high or low temperatures may break down the stevioside compound, which could change how sweet it is and how stable it is. Formulators must strike a balance between optimal solubility and preserving the integrity of the stevioside powder. Typically, a temperature range of 20-50°C is considered suitable for stevioside dissolution in most applications, with specific temperatures dependent on the formulation requirements and the desired end product.

PH influence on stevioside powder solubility

The pH of the solution significantly impacts the solubility of stevioside powder. Stevioside exhibits better solubility in slightly acidic to neutral pH ranges, typically between 4 and 7. This pH range aligns well with many food and beverage applications, making stevioside powder a versatile ingredient. In highly acidic environments (pH < 3), stevioside may undergo hydrolysis, potentially affecting its sweetness profile and stability. Conversely, in alkaline conditions (pH > 8), the solubility of stevioside powder may decrease, leading to potential precipitation or reduced sweetness intensity. Formulators must carefully consider the pH of their product matrix and adjust accordingly to ensure optimal stevioside powder solubility. In some cases, buffering agents or pH adjusters may be necessary to maintain the ideal pH range for stevioside dissolution throughout the product's shelf life.

Particle size and its effect on stevioside solubility

The particle size of stevioside powder significantly influences its solubility and dissolution rate. Generally, smaller particle sizes lead to improved solubility due to the increased surface area available for interaction with the solvent. Finely ground stevioside powder dissolves more quickly and completely compared to coarser particles. This is especially important when the substance needs to dissolve quickly, like in fast drinks or powdered mixes. Manufacturers often offer stevioside powder in various particle sizes to cater to different formulation needs. Micronized or nano-sized stevioside particles can further enhance solubility and may be beneficial in challenging applications where complete dissolution is critical. However, formulators should be aware that extremely fine particles may lead to dusting issues during handling and processing. Balancing the desired solubility characteristics with practical processing considerations is essential when selecting the appropriate stevioside powder particle size for a given application.

How can stevioside powder be effectively incorporated into liquid formulations?

Pre-dissolving techniques for stevioside powder

Effectively incorporating stevioside powder into liquid formulations often begins with pre-dissolving techniques. One common method is to create a concentrated stevioside solution before adding it to the main formulation. In this method, the stevioside powder is mixed with a small amount of warm water or another liquid that works well, usually when the temperature is between 40°C and 50°C. Gentle shaking or motion helps make sure that everything dissolves completely. The concentrated solution that is made can then be easily added to the main liquid mixture. This makes sure that the sweetness is spread out evenly. A high-shear mixer or homogenizer can also be used to mix the stevioside powder straight into the liquid base. This method works especially well for bigger batches or liquids that are harder to stir. In some cases, formulators may choose to combine stevioside powder with other dry ingredients before adding them to the liquid base, which can help prevent clumping and promote uniform distribution.

Emulsion-based strategies for stevioside incorporation

Emulsion-based strategies can be highly effective for incorporating stevioside powder into liquid formulations, especially in oil-based or high-fat systems. One approach is to create a water-in-oil emulsion where stevioside powder is first dissolved in the water phase. Then, this emulsion can be added to the oil-based mixture to make sure that the sweetness is spread out evenly in the result. To make a stable mixture of stevioside powder in a liquid matrix, emulsifiers or detergents can also be used. This method works especially well for drinks or liquid medicines that need to be clear and stable. There are formulators who choose microemulsion methods because they can make stevioside powder more soluble and bioavailable. Usually, these systems include water, oil, and detergents that make nanoparticle-sized droplets. These droplets dissolve the stevioside and keep it stable in the mixture.

Encapsulation methods for improved stevioside powder dispersion

There are new ways to improve the stability and spread of stevioside powder in liquid products by encapsulation. Microencapsulation techniques, such as spray drying or coacervation, can be used to create stevioside-containing particles that are easily dispersible in liquids. Because they are enclosed, these types can keep the stevioside from breaking down because of changes in pH or temperature. Cyclodextrins are another method. They can join with stevioside molecules to form inclusion complexes. This makes them more solid and smooth to dissolve in water. Another potential way is liposomal encapsulation, which can be used to add stevioside powder to functional drinks or nutritional mixes. Using this method, stevioside molecules are wrapped in lipid bilayers, which can make it easier for it to dissolve in both water- and lipid-based systems and may also make it more bioavailable.

What are the best practices for maintaining stevioside powder stability in dry mix formulations?

Moisture control strategies for stevioside powder preservation

Maintaining the stability of stevioside powder in dry mix formulations requires careful attention to moisture control. Too much water can cause the stevioside powder to clump, break down, and possibly grow microbes, which lowers its quality and effectiveness. One effective way to keep the surroundings dry is to use desiccants or moisture absorbers inside the package. In this case, silica gel packets or molecular sieves can work really well. Another way is to add anti-caking agents, like silicon dioxide or tricalcium phosphate. These can help keep the stevioside powder's ability to flow freely in dry mixes by stopping it from absorbing water. Formulators should also consider the hygroscopicity of other ingredients in the formulation and how they might interact with stevioside powder over time. Proper packaging selection, such as using moisture-barrier materials or multi-layer pouches, can further protect the stevioside powder from environmental humidity.

Particle size optimization for stevioside powder in dry blends

Improving the particle size of stevioside powder is important for making sure that it is evenly distributed and doesn't separate in dry mix formulas. Usually, making sure that the stevioside powder particles are the same size as the other materials in the mix helps keep everything uniform. Micronized stevioside powder with particles sized between 10 and 50 microns may work for tiny powders. For grainy mixes, bigger stevioside particles or agglomerates might be better to keep the blend's structure and stop it from sifting. Some companies make powdered types of stevioside that are made to be used in dry mix recipes. These grains can make things move better and make them less dusty while they are being processed and handled. Controlling the particle size distribution of stevioside powder can also help improve how well it dissolves when the dry mix is restored. This will help make sure that the end product has a consistent sweetness profile.

Compatibility considerations with other dry ingredients

When formulating dry mixes with stevioside powder, it's essential to consider its compatibility with other ingredients. Stevioside powder is generally stable in the presence of most common food ingredients, but certain combinations may affect its performance or stability. For instance, highly acidic ingredients in powdered form may potentially hydrolyze stevioside over time, especially if moisture is present. Stability studies should be done by formulators to make sure that the sweetness profile stays the same over the course of the product's shelf life. Some ingredients, like some proteins or fibers, might react with stevioside powder and change how it dissolves when the mix is mixed again. If this happens, changing the order in which the ingredients are added or using compressed types of stevioside powder can help fix the problems. It's also important to think about the color changes or off-flavors that could happen when stevioside powder interacts with other ingredients. This is especially true for products that have a long shelf life or are subject to changing weather.

Conclusion

In conclusion, understanding the solubility and formulation guidelines for stevioside powder is crucial for successful product development. By considering factors such as temperature, pH, particle size, and compatibility with other ingredients, formulators can optimize the use of this natural sweetener in various applications. Effective incorporation techniques, whether in liquid or dry formulations, ensure consistent sweetness and stability. As the demand for natural, low-calorie sweeteners continues to grow, mastering these guidelines will enable manufacturers to create high-quality products that meet consumer expectations for taste, quality, and clean label requirements.

Shaanxi Fairir Biotech Co., Ltd. is proud to be the leading manufacturer and supplier of high-quality plant extracts since it has always strived to be the best. Our core mission is to provide innovative, sustainable, and effective solutions that meet the evolving needs of the pharmaceutical, nutraceutical, cosmetic, and food industries. For more information or inquiries about our stevioside powder and other plant extracts, please contact us at sales@fairirbiotech.com.

References

1. Zhang, Y., et al. (2019). "Solubility and stability characteristics of stevioside in food systems: A comprehensive review." Food Chemistry, 290, 156-164.

2. Lemus-Mondaca, R., et al. (2018). "Stevia rebaudiana Bertoni: A natural alternative for sugar and artificial sweeteners." Journal of Food Science, 83(7), 1837-1851.

3. Prakash, I., et al. (2020). "Formulation strategies for steviol glycosides: Challenges and opportunities." Trends in Food Science & Technology, 96, 132-141.

4. Gupta, E., et al. (2017). "Stevioside and rebaudioside A – Predominant ent-kaurene diterpene glycosides of therapeutic potential: A review." Journal of Food Science and Technology, 54(12), 3845-3859.

5. Samuel, P., et al. (2018). "Stevia leaf to stevia sweetener: Exploring its science, benefits, and future potential." Journal of Nutrition, 148(7), 1186S-1205S.

6. Yadav, S. K., & Guleria, P. (2021). "Stevioside: A natural sweetener with diverse therapeutic applications." Critical Reviews in Food Science and Nutrition, 61(3), 403-419.

_1751965378790.webp)